My project for the day was to remove and replace the broken ram pinion handle on my 1967 J-head, V-ram, 9x42 Series 1 Bridgeport

It was broken off when I bought the machine about 3 years ago. I figured the ram was stuck and I'd get around to fixing it eventually. Been using the machine ever since with the ram where it currently is.

I decided to investigate the stuck ram this weekend and logged the process under the Bridgeports and Clones heading, "Unstuck my Bridgeport Ram this evening". I figured that was the best place for the main story.

Here I'm going to talk about replacing the ram pinion handle.

As stated, the handle was broken off flush at the pinion. I removed the pinion from the Bridgeport, and clamped it between two v-blocks. I soaked it with penetrating oil the night before, and tried unscrewing the stub with a center punch and a small ball pien while tapping tangentially. I was able to get it to unscrew about a half turn, while working it back and forth but that was as far as it wanted to go.

View attachment 122808

I then center punched the ragged stub, and drilled an axial hole for an easy-out. I hadn't used an easy-out in decades, and had never been very successful, but now I was more mature and patient. Surely I would be successful.

The broken stub did indeed start to unscrew, but I only got it to go another half turn before the easy-out snapped. So much for maturity and patience!

I decided to attempt to remove the easy-out, so I drill a couple holes around it and was able to remove the broken easy-out piece.

Eventually I was able to enlarge the hole in the stub, and carefully remove the pieces of the broken handle, but not without some damage to the threads within the hole. I decided to drill and re-tap the 3/8in hole to 1/2in.

I used a pin gauge and v-blocks to align the existing hole in the pinion, on axis with the Bridgeport spindle. The setup was a little kludgy but it worked well. I'm not a trained machinist, but an electrical engineer that likes machines.

View attachment 122810

View attachment 122811

I enlarged the hole for 1/2-13. The setup held good and I got a nicely tapped 1/2-13 hole with which to attach a more robust handle. I screwed in a 6 inch long grade 8 bolt to serve as a temporary handle, while I resumed the task of freeing my stuck ram.

View attachment 122813

Pic below is the new handle on the job. I'll find or fabricate a suitable replacement with a ball end eventually.

View attachment 122814

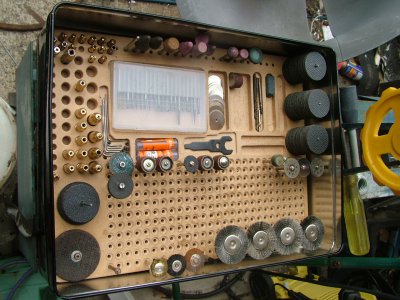

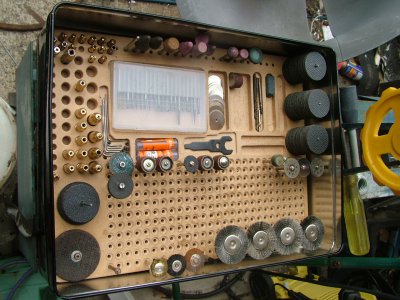

Nothing much, made a holder with my Grandson for some loose rotary tool bits that I had lying around.

Nothing much, made a holder with my Grandson for some loose rotary tool bits that I had lying around.