-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE MAIN DISCUSSION SECTION

- TOOL JUNKIES - Love Tools? This is your forum!

- What Did You Buy Today? Tool Junkie Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2018 Archive

- Thread starter GoceKU

- Start date

- Status

- Not open for further replies.

- Joined

- Jul 14, 2017

- Messages

- 2,448

Today i visited couple of tool markets and bought couple of old machinist tools, first i found this protractor, some surface rust, but the numbers are still nicely visible, then i found this old rusty MT3 live centre the bearings feel smooth so decided i'll spend some time cleaning it up and have it for a spare, also made a package deal for the 40-75mm cone drill, and lastly i bought this 24mm new taper drill bit, MT1 to MT3 reducer and 13,75mm drill, not a bad visit.

- Joined

- Jul 14, 2017

- Messages

- 2,448

Today i stopped by a scrapyard i've bought steel pieces before and bought a full box of metal castings and round bar cut offs i'm pretty sure the steel castings are for making bearings, not sure how hard they are but should come in handy, also bought this bent piece of round stock, mechanical tachometer and the rusty machined piece, all in less than 10$.

- Joined

- Oct 18, 2016

- Messages

- 2,872

A couple of CL finds today. I've been wanting to replace the horrible Chinese DP vice I've had for the last 20 years. This one is Taiwanese,

but appears very well made: nicely machined, jaws align properly, smooth in operation after a clean up and lube session. It's a huge

improvement over the old one. While I was at it I bought a couple of old forged steel Wilton C-clamps. None of this stuff appeared to

have ever been used.

- Joined

- Oct 21, 2017

- Messages

- 504

I took a punt on a few items of tooling on eBay and picked up these

2x MGCH08 solid carbide holders and a box of grooving tips. I already have a few other MGCH 08 and MGCH 06 bars but I'm finding that as I use them more it's very handy to be able to leave one with a threading insert and one with a grooving insert and still have one for less frequently used tips.

The beauty of these things is that all tips are available in LH and RH and you can use them on the lathe for boring and back-boring, internal and external threading, internal and external grooving and on the mill for grooving and thread milling ;-)

2x MGCH08 solid carbide holders and a box of grooving tips. I already have a few other MGCH 08 and MGCH 06 bars but I'm finding that as I use them more it's very handy to be able to leave one with a threading insert and one with a grooving insert and still have one for less frequently used tips.

The beauty of these things is that all tips are available in LH and RH and you can use them on the lathe for boring and back-boring, internal and external threading, internal and external grooving and on the mill for grooving and thread milling ;-)

- Joined

- Nov 28, 2016

- Messages

- 2,357

My latest buy...

I didn't get a screaming deal on it, but I've been looking for a good saw for a year now and finally decided I was going to have to increase my spending limit for one.

I was finding project saws in my original price range, but really wanted a 'plug and play'...

I think this is going to be a good fit in my shop.

-Bear

I didn't get a screaming deal on it, but I've been looking for a good saw for a year now and finally decided I was going to have to increase my spending limit for one.

I was finding project saws in my original price range, but really wanted a 'plug and play'...

I think this is going to be a good fit in my shop.

-Bear

- Joined

- Apr 28, 2014

- Messages

- 3,590

Nice Score!My latest buy...

I didn't get a screaming deal on it, but I've been looking for a good saw for a year now and finally decided I was going to have to increase my spending limit for one.

I was finding project saws in my original price range, but really wanted a 'plug and play'...

I think this is going to be a good fit in my shop.

-Bear

- Joined

- Jul 20, 2014

- Messages

- 1,386

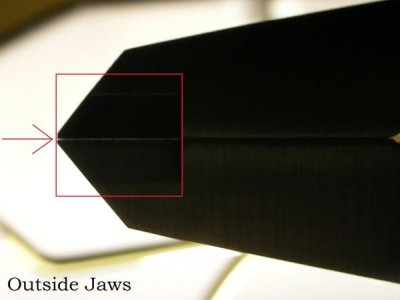

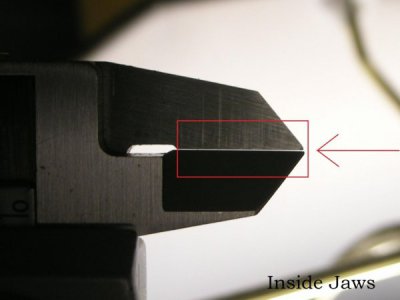

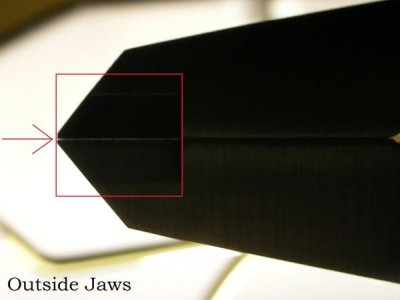

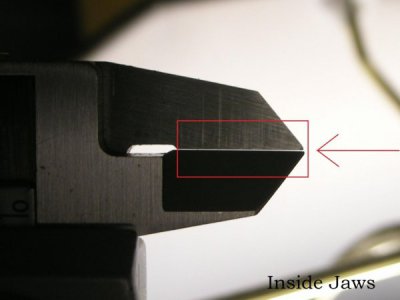

Mitutoyo re-issued a newer version of their 505 series 736 model 6" dial caliper with carbide jaws.

The model no loner needs TiN coating on the beams. Mitutoyo using a better grinding process. I bought this set new because I needed a shop set, and I was tired of buying used calipers with gaps in the jaws from wear. I wanted another Swiss caliper, vintage Tesa or Etalons, but all of them were junk, so I bought these Japan made Mitutoyos. Dead accurate. The carbide jaws will prevent premature wear. The last photo shows the kind of wear that is seen is many used (and some new!) calipers. I purchased and returned 3 Ebay calipers before I bought the new Mitutoyos. 505-736 6" inch/metric dial calipers with carbide jaws.

The model no loner needs TiN coating on the beams. Mitutoyo using a better grinding process. I bought this set new because I needed a shop set, and I was tired of buying used calipers with gaps in the jaws from wear. I wanted another Swiss caliper, vintage Tesa or Etalons, but all of them were junk, so I bought these Japan made Mitutoyos. Dead accurate. The carbide jaws will prevent premature wear. The last photo shows the kind of wear that is seen is many used (and some new!) calipers. I purchased and returned 3 Ebay calipers before I bought the new Mitutoyos. 505-736 6" inch/metric dial calipers with carbide jaws.

Last edited:

- Joined

- Jan 22, 2017

- Messages

- 104

Well I'd been looking around ebay, etc for a Noga base. We had gone down to Abilene, TX and stopped by a flea market that we stop at occasionally. They do have a couple of vendors that carry tools of various sort. Today, just what I was looking for. Noga magnetic base with an SPI 0.5" indicator. Just a shelf away was a set of fractional transfer punches and also a couple of aluminium bars for good measure. Figured it was a good day.

Last edited:

- Joined

- Jan 29, 2017

- Messages

- 311

Mitutoyo re-issued a newer version of their 505 series 736 model 6" dial caliper with carbide jaws.

The model no loner needs TiN coating on beams. Mitutoyo using a better grinding process. I bought this set new because I needed a shop set, and I was tired of buying used calipers with gaps in jaws from wear. I wanted another Swiss caliper, vintage Tesa or Etalons, but all of them were junk, so I bought these Japan made Mitutoyos. Dead accurate. The carbide jaws will prevent premature wear. The last photo shows the kind of wear that is seen is many used (and some new!) calipers. I purchased and returned 3 Ebay calipers before I bought the new Mitutoyos. 505-736 6" inch/metric dial calipers with carbide jaws.

That point wear is from machinists using their calipers as marking gauges I suspect. I always lightly clamp my caliper jaws around the shirt edge between a pair of buttons on my shirtfront and draw away to clean them prior to zeroing and checking, its my habit.

Quality calipers should have a pair of adjusting screws to adjust parallelism also, you have to have a light feel when using calipers, none of this clamp the crap out of the work to get the best measurement. My Mitutoyo's (digital 500-322)were purchased in 1989 and cost me AU$250 then and are still able to measure 0005" repeatedly. The case is a lot worse for wear though.

- Status

- Not open for further replies.