David Best has the several of the Haas face mills if I recall the HOP Octagon and the HRNP rectangular negative/positive inserts, I have the HS6NPTrigon in 2.5". I use mine with the HMP20 inserts for mild steel, stainless and aluminum and get very smooth finishes, also some significant shouldering and have no problems with my 3Hp mill. If just light surfacing then the Octagon gives more cutting edges, I already had 2" and 4" Iscar octagon face mills, the larger for aluminum, the smaller for ferrous metals, as well as some from Sandvik. The Haas HS6NP performs very well in a wide range of materials with the inserts noted, but I have not used it for harder ferrous metals. Most of the inserts can be both rotated and also flipped, so the Trigon has 6 cutting edges, they are a positive rake at the cutting edge. I find the HS6NP to be very versatile, If I am just doing surfacing then I well switch to an octagon or a 45 degree square insert type. These run just over $400 with a CAT40 holder and 30 inserts.

New Mill owner.. I would like to purchase a general purpose face mill. I have a 2HP (PM833TV) mill with an R8 spindle.... A little overwhelmed with the amount of chinese garbage and types of cutters. I want something "good quality" - Meaning, something I'll be happy with for a very long time...

www.hobby-machinist.com

Explore high-quality Shell Mill Bodies for precision machining. Our range includes durable and efficient milling solutions for various applications. Find the perfect Shell Mill Body for your machining needs.

www.haascnc.com

HS6NP – Haas Sq Shoulder 6 Negative Positive with HMP20 inserts

HS6NP, 3" Diameter Complete Shell Mill Kit, CT40 Holder, 2" Gage Length, Grade HMP20, TSC

www.haascnc.com

HRNP – Haas Rectangle Negative Positive with HMP20 inserts

HRNP, 3" Diameter Complete Shell Mill Kit, CT40 Holder, 2" Gage Length, Grade HMP20, TSC

www.haascnc.com

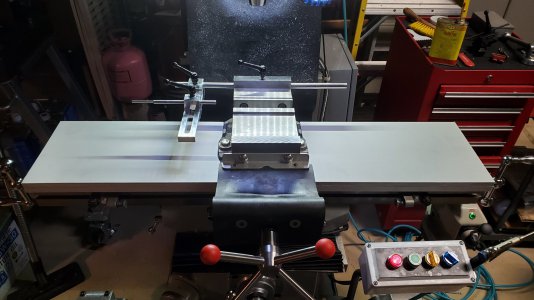

I added taller steel jaws to the front and back of my vise and then surfaced it with the Haas HS6NP, also deep wide shouldering in 7075 aluminum with very nice finish.

View attachment 439669