- Joined

- Feb 7, 2013

- Messages

- 792

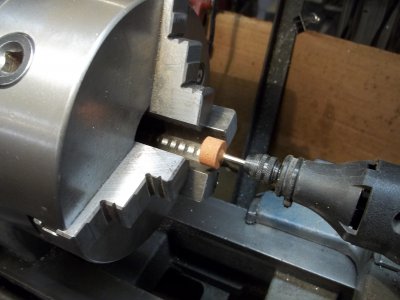

Thanks for the info everyone. After some grinding, below is as close as I could get the jaws. I am sure now I will need to grid all three as described by Iron Man in order to actually get them accurate. @ iron man, if you could post some setup pictures that would be great, I am not quite sure I understand what your doing with the keystock. I do have a dremel, and various stones and diamond bits, I will just have to come up with something to hold it.

Thanks

View attachment 48241

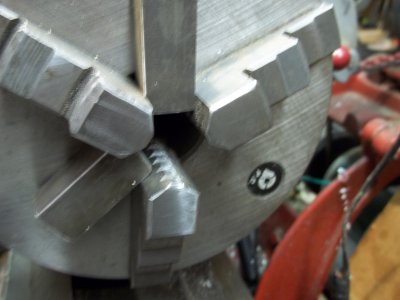

I will set that up and take some pic's right now. be back in a while.. Ray

Last edited: