I do relatively simple work on pool cue tips and ferrules. Right now I have a steady rest that is not actually very steady. It is three rollers in which the bearings have significant play. Consequently, I am not able to work as precisely as I would like. I want to mount a 3 jaw chunk on bearings but it must allow the cue shaft to pass through from behind. The cue will collet is about 16 mm diameter. I would prefer just purchasing this assembly but will build it if I must. Any ideas would be helpful. Hopefully you can picture what I am trying to describe, If not, I will provide pictures.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 Jaw Chuck, work through steady rest

- Thread starter vin421

- Start date

A pic would help me anyhow, 3jaw chuck on bearings ?

Yes, I have ordered some higher end bearings and hopefully that will reduce the throw out. Problem no. 2 is centering the work all the time. I can do it but it requires patience and I do it by eye. I was thinking a 3 jaw chuck might make it easier and more accurate.Could you not just change the bearings in the arms of your current steady rest?

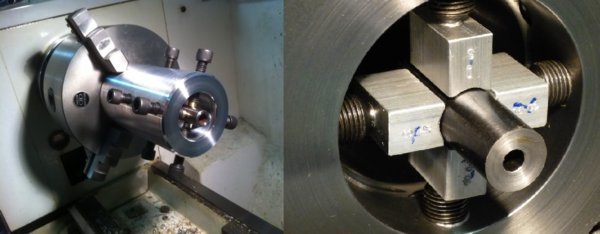

Thanks for the replies. I have discovered the item I am looking for at a billiard supply house. I guess that is the obvious place to have looked. It can be observed in action on YouTube, https://www.youtube.com/watch?v=mwMm0cdhdQo&feature=em-comments at 4:19 - 4:26. Problem now is...$150 plus about $100 shipping to Thailand. I think I can build one for a lot less considering I can get a decent Chinese made chuck for less than $50. So, starting with the standard 3 jaw chuck.....

If anyone has any advice on what I need to complete the project I'd be interested in hearing.

If anyone has any advice on what I need to complete the project I'd be interested in hearing.

Glad to see you found the right place - Now that I've seen what you are looking for I realize your need. If you are doing

quality cues you may want to go for the quality tool.

Yes sir! No substitute for quality tools. I went ahead and forked out the dough.

Now I have to deal with the stress of checking the mail for a delivery notice every day for the next three weeks. I have some virtues. Patience ain't one of 'em.

- Joined

- Jun 12, 2014

- Messages

- 4,810

Not really unless you have a means to set the chuck so that it runs true. A few things to consider, and it partly depends on your lathe, size and how you use it. What is most commonly used is a spider which is a round tube that attaches to your spindle/chuck or you could use a bearing in your steady rest with a spider running on the bearing. A spider usually has 4 Allan screws to adjust/center the position. The tips of the screws are often brass tipped or can have fingers. You use a dial indicator or test indicator to set center very quickly, this is very commonly done with 4J independent chucks.I was thinking a 3 jaw chuck might make it easier and more accurate

The other alternative is to get a mini chuck in the 100mm range either 3J scroll or 4Jindependent, turn a backing plate to fit a bearing that would be secured by your steady rest or fabricate a steady rest block. Not a difficult task, but at the end of the day this approach will probably be more expensive. The price of a chuck with shipping, a bearing and materials will be in the $150-200 range.

Thanks! Very informative. You're second suggestion is what I had planned to do. That is until I saw the item I was looking for being used on YouTube:

and it is available at Cue Man Billiards.

https://www.cuesmith.com/steady-rest-with-deluxe-chuck-mid-size.html

I guess a cue supply parts house was the obvious place to look. With shipping from the US to Thailand, it will be around $250 but, it will be much better than what I have which is little more than a skate board wheeled steady rest.

https://www.cuesmith.com/steady-rest-with-deluxe-chuck-mid-size.html

I guess a cue supply parts house was the obvious place to look. With shipping from the US to Thailand, it will be around $250 but, it will be much better than what I have which is little more than a skate board wheeled steady rest.