- Joined

- Feb 2, 2013

- Messages

- 3,901

In my normal work, changing out motors is a constant part of my job.

Another part of my job is purchasing motors for replacement of OEM motors, iv'e gotten very good at it!!!

I have found over the years that most 3 phase motors are constructed in the same manner using similar parts.

The only thing that really changes is the size of the components the motor was constructed from and the materials the motor is constructed from as well.

Not to say that all 3 phase motors are created equal, but rather, i'd say similar.

I have Hobart Meat Saw model#5801 that has a faulty motor.

bear in mind this saw has operated for 6 years without any type of maintenance performed since it was new.

the Company that owns the saw pushed it into the corner when the motor started grumbling and left it there to rot.

The company was given a quote from the manufacturer to repair the saw.

The estimate was an astronomical sum that was more expensive than a new saw.

They gave me a call for a second opinion....

:notthis:

The manufacturer, Hobart is known for bending a customer over a barrel.

The simplest of parts can literally cost the end user hundreds of dollars, and the manufacturer has no sympathy.

To add insult to injury, rarely does Hobart show up in the same week that a service call is placed, putting their customers who depend on the machinery in a real bad position.

Hobart's attitude has made me a lot of money over the years, i hope they don't wake up to smell the coffee:lmao:

I got the call to inspect the saw from the newly contracted customer and reassured them i could make the saw purr like a kitten for less than the cost of a new saw.

I prepared the quote and the customer was nicely surprised as to the difference in projected cost to repair.

i was immediately issued a purchase order and authorized to continue my repair.

Hobart has a bad habit of making items OEM, and this makes going around their cute little system a difficult task sometimes...

They want you to buy anything for their machines from them. They will go as far as cutting special odd threads on certain bolts

just to trip independent service agencies from putting their hands in the cookie jar, so to speak.

Being in the business for a while and just having a think outside of the box mentality, has made me come up with many different was to skin cats of all names and manufacture. this case is no exception.

The motor from the OEM is a general electric manufactured motor. NOT AVAILABLE EXCEPT TO HOBART INC,:angry: and Hobart wants, now get this...$1,500.00 for a 3 hp 3 phase motor, i was told this by the parts rep for my area

:roflmao: was my response....

Knowing a lot about electric motors, i was not worried about finding a replacement. FR56CZ Code J was the OEM Frame

The motor was manufactured to NEMA Standards, so that means other manufacturers manufacture the same frame.

If another manufacturer makes the same frame, they usually make very similar shafting configurations.

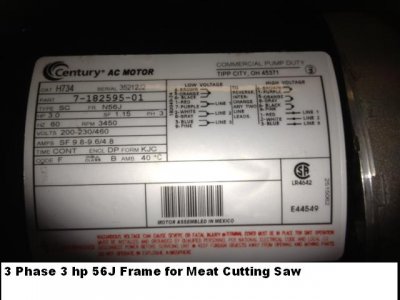

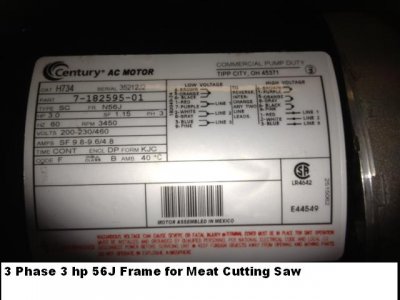

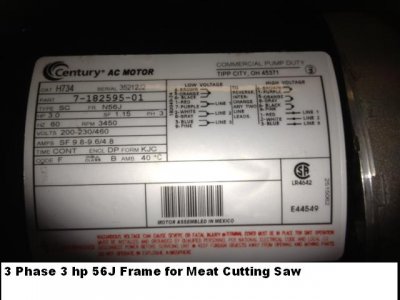

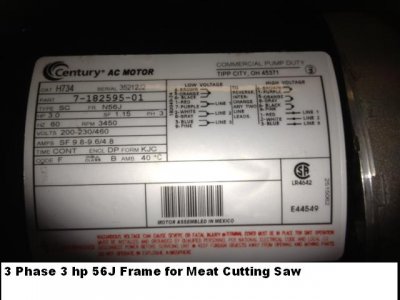

The replacement i found happens to be a 56 J frame pump motor. It's manufactured by Century Motors

The only problem is that the motor is a plain shaft threaded to 7/16-20 male threads.

I need a Threaded and keyed shaft to retain a drive gear.

i disassembled the brand new replacement motor and removed the rotor assembly.

I trammed the mill and performed the set up to put a woodruff key in the 5/8" stainless steel shaft.

I clamped the rotor on 2 VEE blocks to keep it off Beatrice's bed

I was lucky enough to get a good tool score a couple months back, in the haul there were some pristine slot cutters!!!!:biggrin:

i Went to one of my Machinery's Handbooks and looked at the chart for woodruff keys the chart said #11, i just happen to have one to do the job!!:thumbsup:

i located the shaft and locked the X axis.

I Touched off on the top of the shaft. i zeroed the dial and raised the knee .406" to cut on center of the 5/8" shaft

I touched off on the Y axis, zeroed the dial preparing to cut to a depth of .215" as to specifications.

I used a 50/50 mixture of Bacon Grease and Sulfured cutting oil on this run!!

the cutter was very sharp, even though the shaft end wasn't supported , i was able to take light pressure cuts with little resistance offered by the stainless steel shaft.

i thought for sure i was going to have some issues, that fear was not to come true hew:

hew:

in the morning, i'll reassemble the motor and bench test before i make the trip to do the installation in the field.

I was able to purchase the motor for less than $400 shipped.

I'll still sell it for $1,500.00 and put the $1,100.00 in my pocket, i gotta pay for the mill somehow..

she just needs one more small job and she paid for herself!!!

I wish to encourage others who have been told you can't do this or that to prove them wrong!!!

You can do anything you devote yourself to, improbable as it may seem.

Think outside of the box!!!

Thanks for reading.

I welcome questions and comments...

Another part of my job is purchasing motors for replacement of OEM motors, iv'e gotten very good at it!!!

I have found over the years that most 3 phase motors are constructed in the same manner using similar parts.

The only thing that really changes is the size of the components the motor was constructed from and the materials the motor is constructed from as well.

Not to say that all 3 phase motors are created equal, but rather, i'd say similar.

I have Hobart Meat Saw model#5801 that has a faulty motor.

bear in mind this saw has operated for 6 years without any type of maintenance performed since it was new.

the Company that owns the saw pushed it into the corner when the motor started grumbling and left it there to rot.

The company was given a quote from the manufacturer to repair the saw.

The estimate was an astronomical sum that was more expensive than a new saw.

They gave me a call for a second opinion....

:notthis:

The manufacturer, Hobart is known for bending a customer over a barrel.

The simplest of parts can literally cost the end user hundreds of dollars, and the manufacturer has no sympathy.

To add insult to injury, rarely does Hobart show up in the same week that a service call is placed, putting their customers who depend on the machinery in a real bad position.

Hobart's attitude has made me a lot of money over the years, i hope they don't wake up to smell the coffee:lmao:

I got the call to inspect the saw from the newly contracted customer and reassured them i could make the saw purr like a kitten for less than the cost of a new saw.

I prepared the quote and the customer was nicely surprised as to the difference in projected cost to repair.

i was immediately issued a purchase order and authorized to continue my repair.

Hobart has a bad habit of making items OEM, and this makes going around their cute little system a difficult task sometimes...

They want you to buy anything for their machines from them. They will go as far as cutting special odd threads on certain bolts

just to trip independent service agencies from putting their hands in the cookie jar, so to speak.

Being in the business for a while and just having a think outside of the box mentality, has made me come up with many different was to skin cats of all names and manufacture. this case is no exception.

The motor from the OEM is a general electric manufactured motor. NOT AVAILABLE EXCEPT TO HOBART INC,:angry: and Hobart wants, now get this...$1,500.00 for a 3 hp 3 phase motor, i was told this by the parts rep for my area

:roflmao: was my response....

Knowing a lot about electric motors, i was not worried about finding a replacement. FR56CZ Code J was the OEM Frame

The motor was manufactured to NEMA Standards, so that means other manufacturers manufacture the same frame.

If another manufacturer makes the same frame, they usually make very similar shafting configurations.

The replacement i found happens to be a 56 J frame pump motor. It's manufactured by Century Motors

The only problem is that the motor is a plain shaft threaded to 7/16-20 male threads.

I need a Threaded and keyed shaft to retain a drive gear.

i disassembled the brand new replacement motor and removed the rotor assembly.

I trammed the mill and performed the set up to put a woodruff key in the 5/8" stainless steel shaft.

I clamped the rotor on 2 VEE blocks to keep it off Beatrice's bed

I was lucky enough to get a good tool score a couple months back, in the haul there were some pristine slot cutters!!!!:biggrin:

i Went to one of my Machinery's Handbooks and looked at the chart for woodruff keys the chart said #11, i just happen to have one to do the job!!:thumbsup:

i located the shaft and locked the X axis.

I Touched off on the top of the shaft. i zeroed the dial and raised the knee .406" to cut on center of the 5/8" shaft

I touched off on the Y axis, zeroed the dial preparing to cut to a depth of .215" as to specifications.

I used a 50/50 mixture of Bacon Grease and Sulfured cutting oil on this run!!

the cutter was very sharp, even though the shaft end wasn't supported , i was able to take light pressure cuts with little resistance offered by the stainless steel shaft.

i thought for sure i was going to have some issues, that fear was not to come true

in the morning, i'll reassemble the motor and bench test before i make the trip to do the installation in the field.

I was able to purchase the motor for less than $400 shipped.

I'll still sell it for $1,500.00 and put the $1,100.00 in my pocket, i gotta pay for the mill somehow..

she just needs one more small job and she paid for herself!!!

I wish to encourage others who have been told you can't do this or that to prove them wrong!!!

You can do anything you devote yourself to, improbable as it may seem.

Think outside of the box!!!

Thanks for reading.

I welcome questions and comments...

Last edited: