- Joined

- Sep 27, 2014

- Messages

- 3,123

I’ll be starting a project requiring two 4-40 taped holes in 6061 aluminum 1.5” deep thru hole , 40total

I tried google search for reduced shank 4-40 taps , didn’t turn up anything that would go that deep , any suggestions ?, coatings?

I have a tapmatic that I was thinking of power taping them.

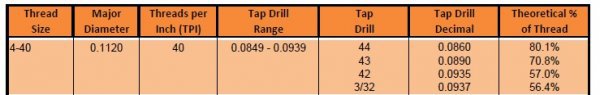

Also remind me about H2-H3-H5 threads

Thanks

I tried google search for reduced shank 4-40 taps , didn’t turn up anything that would go that deep , any suggestions ?, coatings?

I have a tapmatic that I was thinking of power taping them.

Also remind me about H2-H3-H5 threads

Thanks