- Joined

- Feb 2, 2014

- Messages

- 1,065

I have been trying to make the original crank work with a center main bearing but every thing I try just makes it worse. Those pieces will go into the "Too good to throw away" bin and I will start over on a new crank shaft. The new crank will not have needle rod bearings as originally designed but bronze split bushings and it will be flat not round.

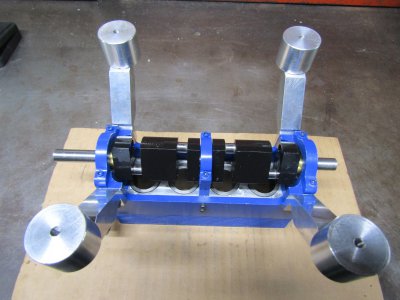

Some of the new pieces for the crank.

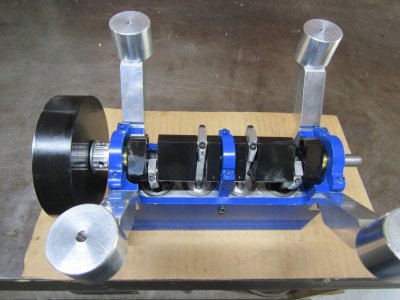

I wanted to make sure that I had enough room for the center bearing so I made and installed the center support.

It will be a close but it does fit and the throws line up with the pistons.

Thanks for looking

Ray

Some of the new pieces for the crank.

I wanted to make sure that I had enough room for the center bearing so I made and installed the center support.

It will be a close but it does fit and the throws line up with the pistons.

Thanks for looking

Ray