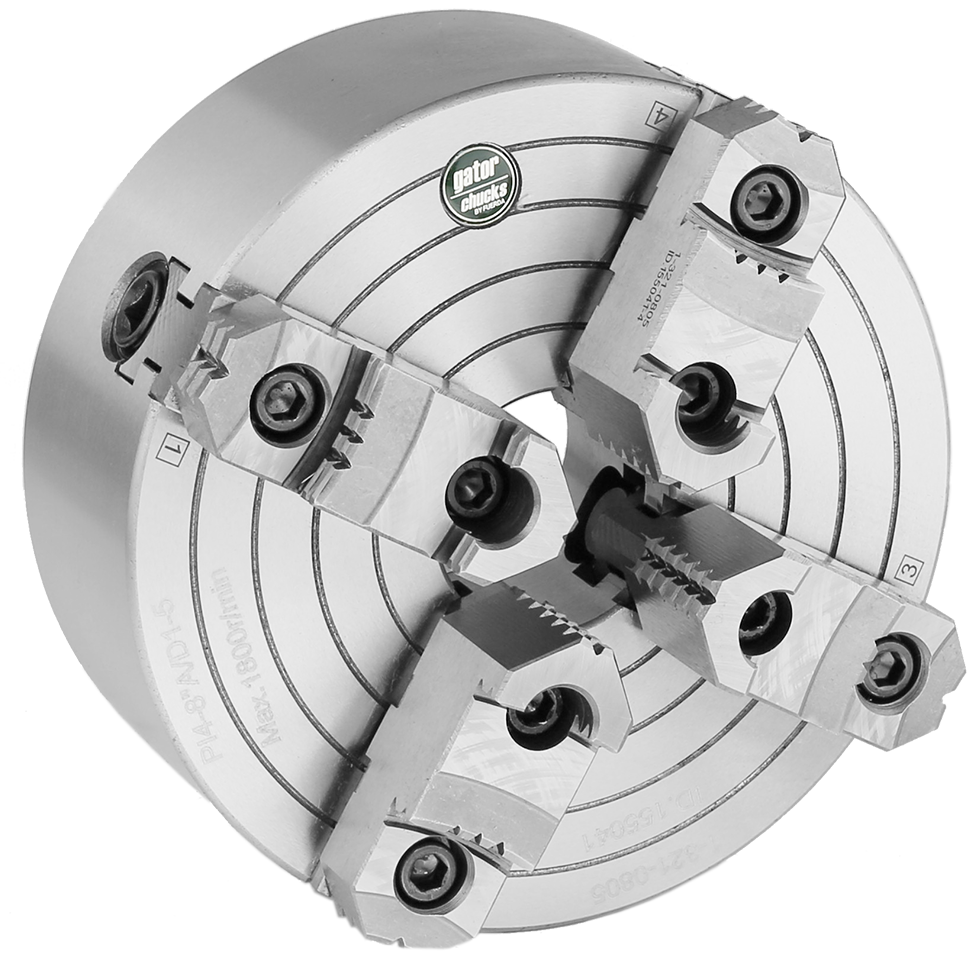

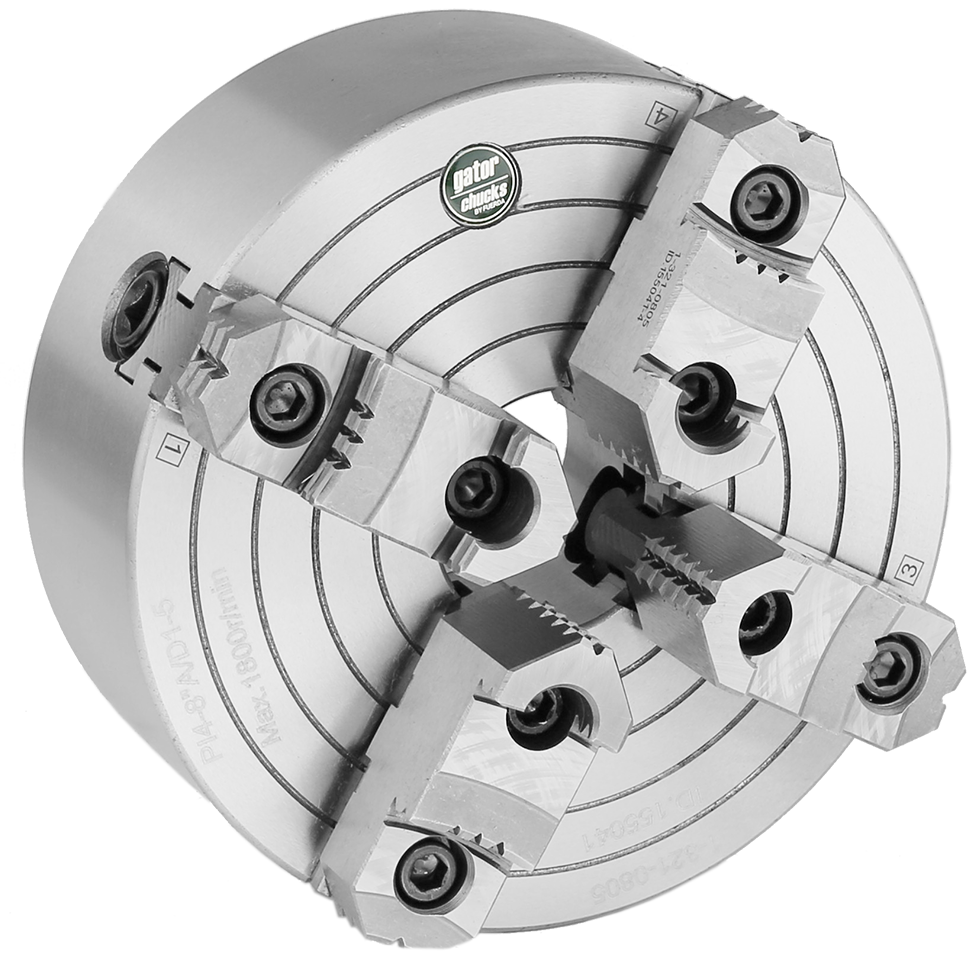

I'm waiting on a PM1228 lathe to arrive and am selecting tools for it, one of which is a 4 jaw chuck. I like the high precision offer from PM, but discovered the Gator chuck in the link that follows. I'm a hobbyist at this point with a lot of ideas and bend toward precise tooling, understanding the dependency on skill with the 4 jaw, and having purchased the PM728 mill first.

I felt the Gator would be the better choice given its apparent versatility; two piece jaws, and t-slots.

I contacted Ajax industries and received a link to the specs and discovered two cons in the process; the actual chuck does not have t-slots as pictured and it weighs ~43 lbs, vs the PM offering at ~33 lbs and has an 1800 rpm max vs. the PM chuck's 3000 rpm max suggesting superior balance.

gatorlathechucks.com

gatorlathechucks.com

Now I believe the PM chuck is probably the better choice, although it does not list a TIR. My creative ideas fall within the small to occasional medium size range. Is my thinking right, or is there other subject matter missed, that needs to be considered. A 6" chuck equivalent would likely be as good, but the 8" range appears to be more favorable in my searches.

Thanks in advance.

I felt the Gator would be the better choice given its apparent versatility; two piece jaws, and t-slots.

I contacted Ajax industries and received a link to the specs and discovered two cons in the process; the actual chuck does not have t-slots as pictured and it weighs ~43 lbs, vs the PM offering at ~33 lbs and has an 1800 rpm max vs. the PM chuck's 3000 rpm max suggesting superior balance.

4-Jaw Independent, 8" Cast-Iron Body, Direct Mount D1-4, 2 PC Hard Rev

Product Information Chuck Type Independent Chuck Mount D1-4 Spindle Type D1-4 Chuck Dia (in) 8 Thru-Hole (in) 2.205 Gripping Range Min-Max (in) .394 - 7.87 Chuck T.I.R (in) 0.0016 Max RPM 1800 Material Cast Iron Jaws 4 Jaw Type 2 PC Hard Reversible Weight Gross (lbs) 42.77 Includes 1 Set of...

gatorlathechucks.com

gatorlathechucks.com

Now I believe the PM chuck is probably the better choice, although it does not list a TIR. My creative ideas fall within the small to occasional medium size range. Is my thinking right, or is there other subject matter missed, that needs to be considered. A 6" chuck equivalent would likely be as good, but the 8" range appears to be more favorable in my searches.

Thanks in advance.