- Joined

- Sep 1, 2020

- Messages

- 1,591

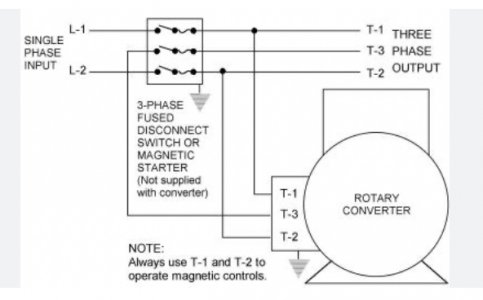

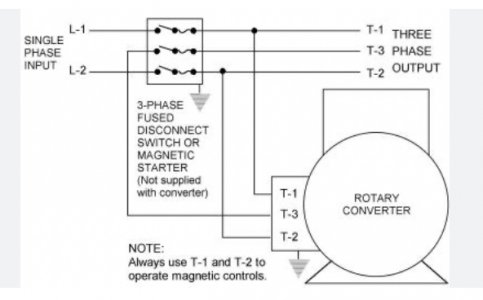

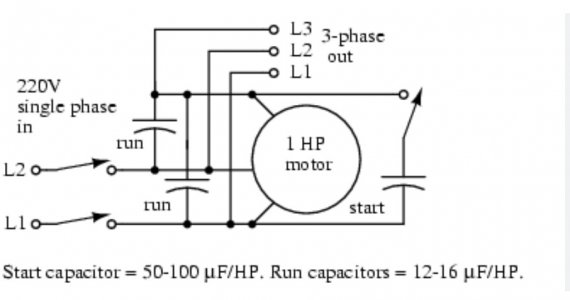

I just got two 7.5 hp 3 phase motors from my uncle, I’m using the better one for a RPC. I have a 60 amp 220 volt circuit running only the RPC. Will this wiring diagram work. The switch I am using is rated for 7.5 hp 3 phase and I’m using 8 gauge wires for all of it. The highest HP machine being powered is a 3 HP lathe, I hope to be able to run the lathe and 2 HP mill at the same time without having issues.