- Joined

- Mar 12, 2022

- Messages

- 132

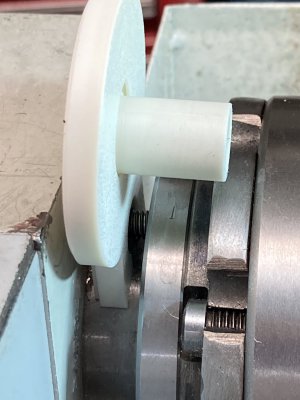

Getting the nuts on and off the chuck studs on my 7x lathe has always been 'tricky' for me. So far, I've been able to hold the nut between the index fingers on both hands and thread it on, but if I had bigger or more arthritic fingers it would be difficult. Even with practice, one of the nuts usually slips from my grip and needs retrieving.

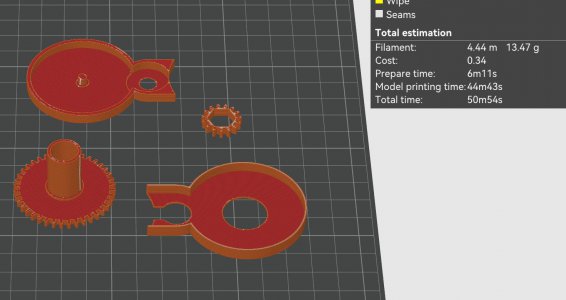

Yesterday I found this ingenious 3D printed "lathe chuck nut mounting tool" by Martin8 on Thingiverse: https://www.thingiverse.com/thing:3245166

It works really well for both removing and attaching chuck nuts on my Sieg 7x14. The curved section near the nut locates against the spindle to 'line up' the nut with the stud.

3D printers are getting more common. If you don't have one, you or a family member may know somebody who does. In my area people advertise 3D printing 'services' on Marketplace. This device is easy to print and doesn't take very long, and the material (filament) cost is less than 50 cents.

Thanks, "Martin8" on Thingiverse!

Yesterday I found this ingenious 3D printed "lathe chuck nut mounting tool" by Martin8 on Thingiverse: https://www.thingiverse.com/thing:3245166

It works really well for both removing and attaching chuck nuts on my Sieg 7x14. The curved section near the nut locates against the spindle to 'line up' the nut with the stud.

3D printers are getting more common. If you don't have one, you or a family member may know somebody who does. In my area people advertise 3D printing 'services' on Marketplace. This device is easy to print and doesn't take very long, and the material (filament) cost is less than 50 cents.

Thanks, "Martin8" on Thingiverse!