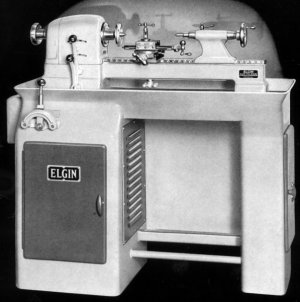

I have been looking for my first lathe and have come across a 9 x 17 Elgin lathe from the 1940s for $600. I figured I couldn't lose much money on the deal, but who knows if that will turn out to be true. It looks exactly like this model in the stock picture and is described as follows at http://www.lathes.co.uk/elgin/:

"Circa 1940 Elgin 9-inch swing by 17 inches between centres precision bench lathe on the maker's enclosed, variable-speed underdrive steel pedestal stand. Running in pre-loaded ball races, the spindle nose could be had a ground thread or with the Hardinge-type quick-release taper and could take 5C collets with a though capacity of 1 inch. Spindle speeds ranged from 120 to 3780 rpm (all without needing to alter any belt position) and, being driven by a 2-speed, 3/4-3/8 h.p. 3-phase motor, were directly reversible. Heavily built for so compact a lathe it weighed a not inconsiderable 1375 lbs."

A 5" 3 jaw chuck is included, a drill bit attachment in the tailstock, but not much else from what I believe.

I was going to start with a small 7" x 16" Chinese variety mini lathe but with this small hefty lathe being available I'll take my chances. I can't believe the weight of this lathe so it should be a bit of challenge to move it.

What should I look out for on this lathe? The lathe hasn't been run in a couple years I believe since the current owner purchased it or moved it from a shop with 3 phase power. I've watched a few videos that describe how to inspect a lathe. I suppose some parts may not be available should something be broken beyond repair. I will need to get a 3 phase converter before I run the machine - maybe purchased from the same seller, or may purchase one via Amazon or Ebay.

Thanks for any input.

Chad

"Circa 1940 Elgin 9-inch swing by 17 inches between centres precision bench lathe on the maker's enclosed, variable-speed underdrive steel pedestal stand. Running in pre-loaded ball races, the spindle nose could be had a ground thread or with the Hardinge-type quick-release taper and could take 5C collets with a though capacity of 1 inch. Spindle speeds ranged from 120 to 3780 rpm (all without needing to alter any belt position) and, being driven by a 2-speed, 3/4-3/8 h.p. 3-phase motor, were directly reversible. Heavily built for so compact a lathe it weighed a not inconsiderable 1375 lbs."

A 5" 3 jaw chuck is included, a drill bit attachment in the tailstock, but not much else from what I believe.

I was going to start with a small 7" x 16" Chinese variety mini lathe but with this small hefty lathe being available I'll take my chances. I can't believe the weight of this lathe so it should be a bit of challenge to move it.

What should I look out for on this lathe? The lathe hasn't been run in a couple years I believe since the current owner purchased it or moved it from a shop with 3 phase power. I've watched a few videos that describe how to inspect a lathe. I suppose some parts may not be available should something be broken beyond repair. I will need to get a 3 phase converter before I run the machine - maybe purchased from the same seller, or may purchase one via Amazon or Ebay.

Thanks for any input.

Chad