- Joined

- Apr 14, 2014

- Messages

- 3,152

I thought I'd start a new thread covering the refreshing of my latest acquisition. That being a Delta 33-400 long arm radial saw. I've been watching Mike's total rebuild on a similar 16" model and have gotten great advice as to some of the intricacies of the machine, and nice improvements he's made. Rather than continue to hijack his thread I thought it would be prudent to move my questions and progress to an independent thread.

The machine I am working on is a 14" radial arm saw as described in the title. I found it at one of my favorite used equipment dealers in October. I purchased it almost immediately and had it delivered to the garage at our family cottage. I've been working on it off and on as time allows, and am finally to the point I can make what are hopefully the final adjustments and put it to work. So far, I've managed to repair some electrical problems, add a new power cord, install some casters for easier movement, and add the necessary 220 single phase outlets to the garage. The next steps are to modify the table for easier use and make all the adjustments for proper cuts.

After the addition of the casters, I reinstalled the original table. I was originally going to shorten it since it's currently 6" long. I've decided to leave it the original length but find it necessary to decrease the depth. It's currently 45" deep which makes it difficult to reach the handle (I'm only 5' 8" tall) when the head is fully retracted to the rear of the machine. I'll get some time tomorrow to make the crosscut, miter, and bevel head adjustments, but then it's time to head home. Hopefully I can get everything aligned properly so the next time up we can start cutting lumber for the new pier decking.

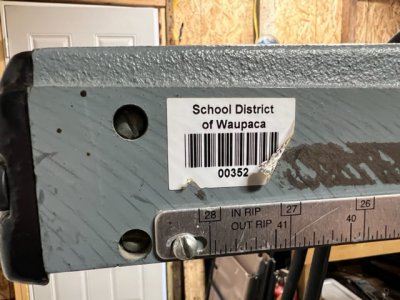

Here are a few pictures of the machine.

The machine I am working on is a 14" radial arm saw as described in the title. I found it at one of my favorite used equipment dealers in October. I purchased it almost immediately and had it delivered to the garage at our family cottage. I've been working on it off and on as time allows, and am finally to the point I can make what are hopefully the final adjustments and put it to work. So far, I've managed to repair some electrical problems, add a new power cord, install some casters for easier movement, and add the necessary 220 single phase outlets to the garage. The next steps are to modify the table for easier use and make all the adjustments for proper cuts.

After the addition of the casters, I reinstalled the original table. I was originally going to shorten it since it's currently 6" long. I've decided to leave it the original length but find it necessary to decrease the depth. It's currently 45" deep which makes it difficult to reach the handle (I'm only 5' 8" tall) when the head is fully retracted to the rear of the machine. I'll get some time tomorrow to make the crosscut, miter, and bevel head adjustments, but then it's time to head home. Hopefully I can get everything aligned properly so the next time up we can start cutting lumber for the new pier decking.

Here are a few pictures of the machine.