I bought an older used German-made lathe, which I’ll post about in detail later. But first, a few quick questions about motor wiring.

The lathe came with a 440/550V motor driven by a 3ph VFD. I’ll be selling those and putting in a nice, nearly new 3hp 220V 1ph Hanning motor I happen to have sitting around. I’ve included a picture of the junction box which unfortunately doesn’t include a wiring diagram. I also can’t find one on the Hanning website. So I’m *guessing* I should connect the Yellow and Blue to one line with Black and Brown to the other line, for (say) Forward. And swap the Blue and Brown connections to get Reverse. So:

Forward = Line1 —> Yel + Blu / Line2 —> Blk + Brn

Reverse = Line1 —> Yel + Brn / Line2 —> Blk + Blu

Question 1: Would it be safe to bench test those configurations, or could I damage the motor if I guessed wrong about the pairs?

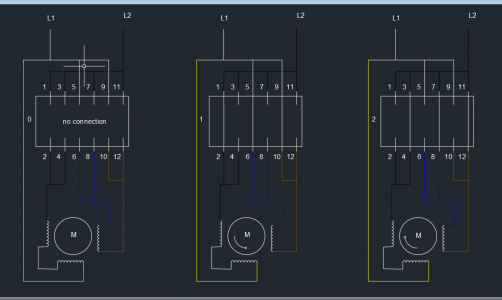

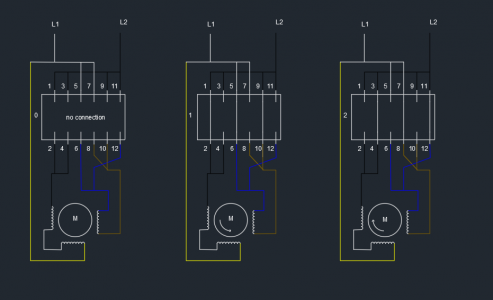

The second issue is about the motor control switch. The shop that had this lathe set up a push button panel and disconnected the original switch. For some reason they didn’t discard it, so I still have the control lever and big modular rotary switch. See pictures. The lever has a lock when at center position (all 12 switches open), so that’s “OFF.” Then there are two detents above and two detents below. So I can have Forward/Reverse with and without the coolant pump. (I have a 230V eighth hp motor to replace the 550V one in the pump).

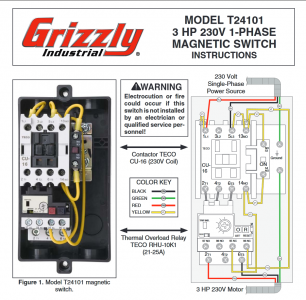

Question 2: Obviously the gear was designed to handle this duty, but is it okay by today’s safety standards? I will add a contactor and E-Stop/Start buttons to shut down line power if needed.

Thanks in advance for your advice.

The lathe came with a 440/550V motor driven by a 3ph VFD. I’ll be selling those and putting in a nice, nearly new 3hp 220V 1ph Hanning motor I happen to have sitting around. I’ve included a picture of the junction box which unfortunately doesn’t include a wiring diagram. I also can’t find one on the Hanning website. So I’m *guessing* I should connect the Yellow and Blue to one line with Black and Brown to the other line, for (say) Forward. And swap the Blue and Brown connections to get Reverse. So:

Forward = Line1 —> Yel + Blu / Line2 —> Blk + Brn

Reverse = Line1 —> Yel + Brn / Line2 —> Blk + Blu

Question 1: Would it be safe to bench test those configurations, or could I damage the motor if I guessed wrong about the pairs?

The second issue is about the motor control switch. The shop that had this lathe set up a push button panel and disconnected the original switch. For some reason they didn’t discard it, so I still have the control lever and big modular rotary switch. See pictures. The lever has a lock when at center position (all 12 switches open), so that’s “OFF.” Then there are two detents above and two detents below. So I can have Forward/Reverse with and without the coolant pump. (I have a 230V eighth hp motor to replace the 550V one in the pump).

Question 2: Obviously the gear was designed to handle this duty, but is it okay by today’s safety standards? I will add a contactor and E-Stop/Start buttons to shut down line power if needed.

Thanks in advance for your advice.