- Joined

- Mar 22, 2013

- Messages

- 215

Gentlemen,

For many years I've had a project in mind to build a Ford flathead V-8 engine. The unique thing about the Ford flathead is that the exhaust runners ran through the water jacket and out the side of the block. Actually this was not a good idea as the extra heat from the exhaust added to the cooling woes of this particular engine. That being said I still wanted to try and build one.

For you fellows who follow my work know I scratch build all of my models from bar stock so after many hours of layouts and drawings I just couldn't come up with a way of fabricating this type of engine from solid. The next plan was to make patterns and coreboxes. I had heard from someone that the old flatheads used 23 cores in the casting process. Having come from a Ford foundry where we cast all types of engines at first I couldn't fathom why this engine would use that many cores. A 302 V-8 engine uses 10 cores and 2 molds, cope and drag. Here again after many hours of layouts and drawings I can now understand why they used so many cores.

Now I've put countless hours into engine and model building but to make all of the coreboxes and patterns required for this engine just seemed a little over the top. I had to ask myself if I really went ahead and made them all and took them to a foundry for casting what would be the cost of making all those cores and casting an engine. Furthermore what would happen if some of the coreboxes go lost or damaged.

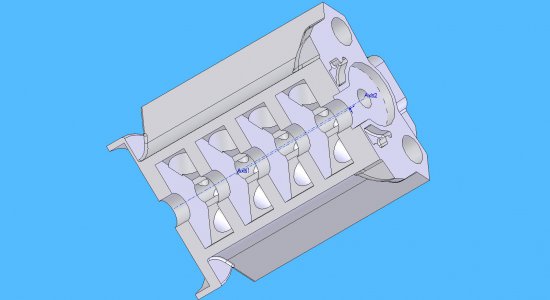

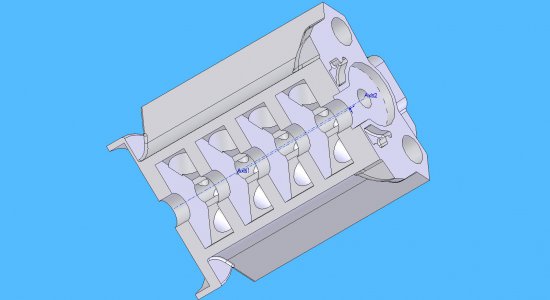

It was time for an entirely new game plan! I still wanted to build a flathead but the Ford type was out of the question so the next best thing is the Cadillac design. The difference in this engine compared to the Ford is that all the ports, intake and exhaust, come out of the top of the block. There are castings out there for this type. They are for the Challenger V-8 that Cole's sells but here again I like to make my own engines so it was back to the drawing board.

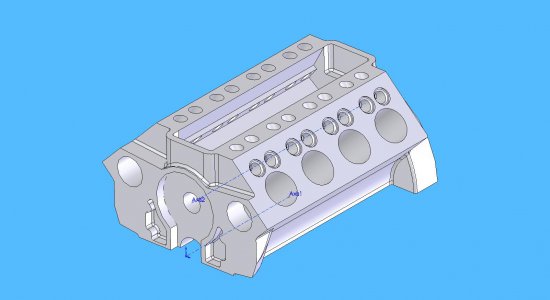

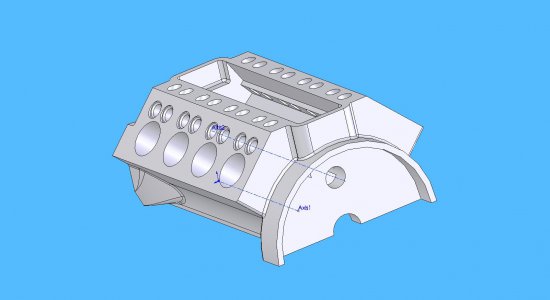

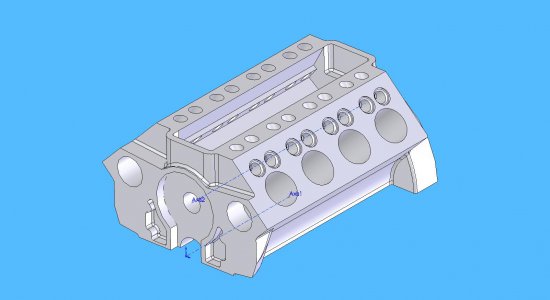

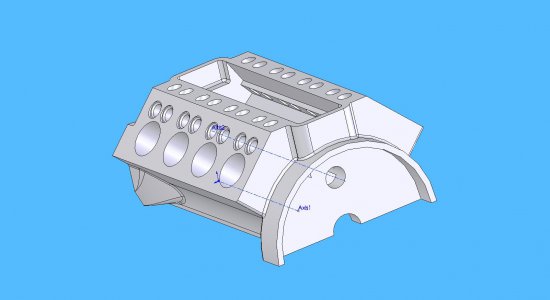

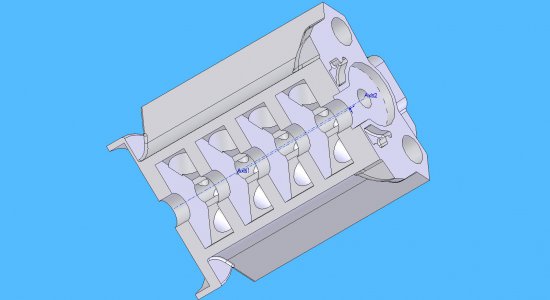

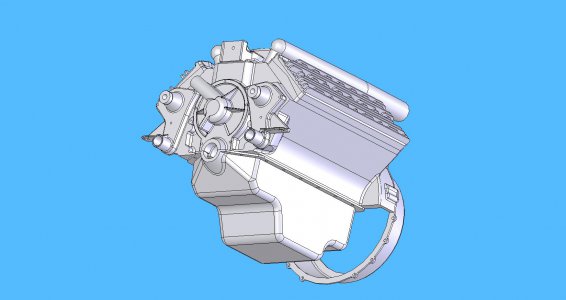

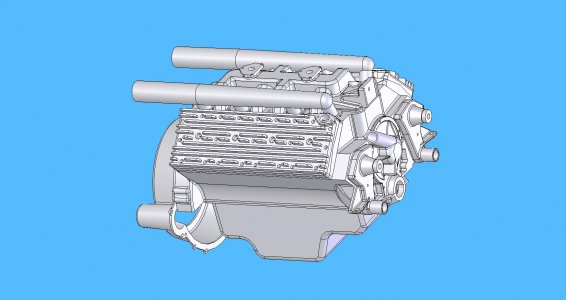

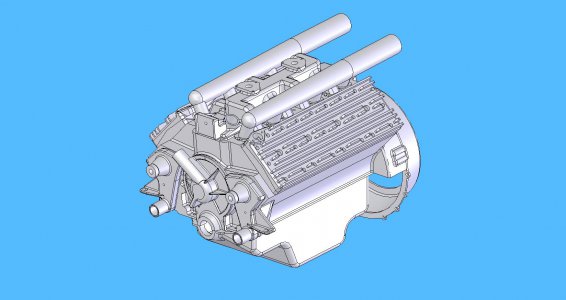

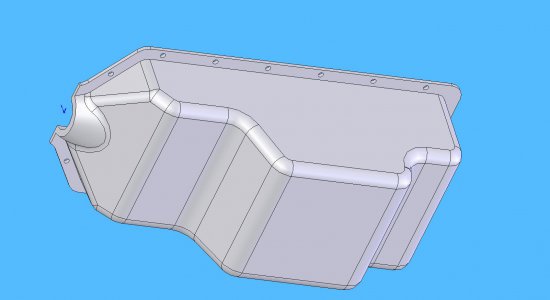

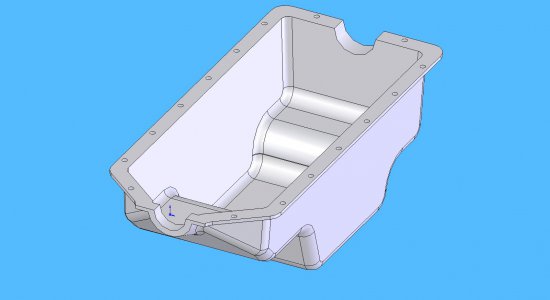

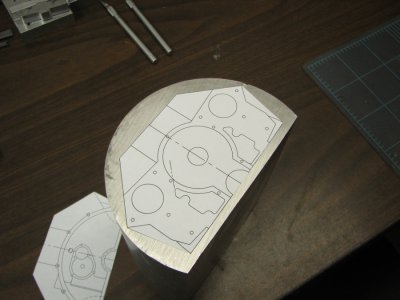

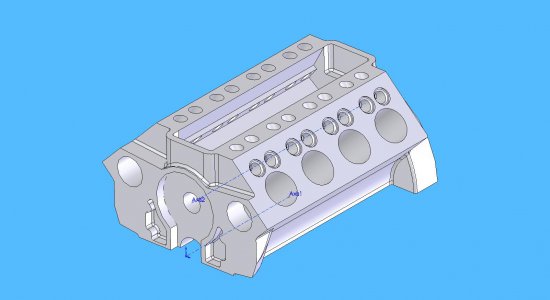

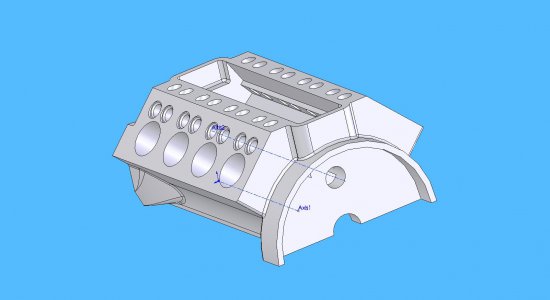

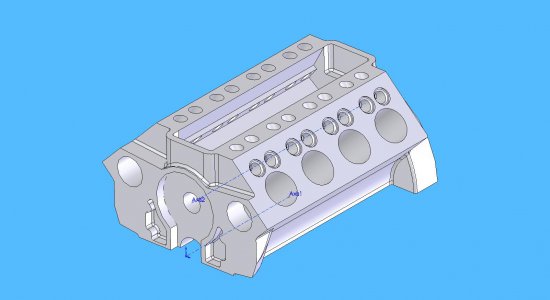

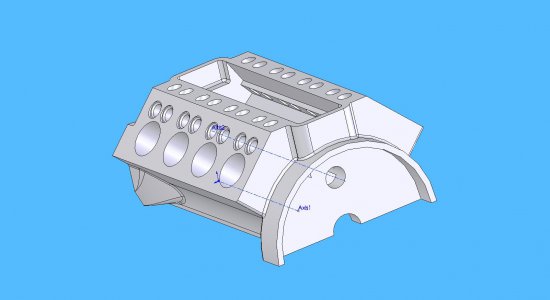

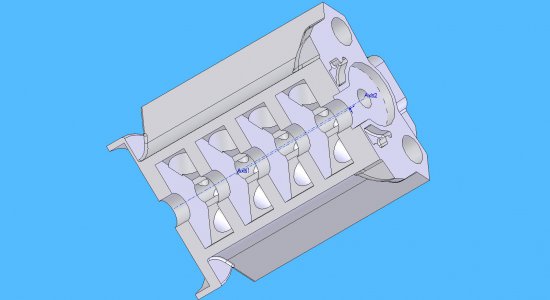

I have the rough Cad drawings made and have converted them into a solid model. I'm presenting them here for your perusal.

With winter just around the corner, I know it's only July but with the way time flies it'll be here in no time so I'm getting a head start on the project.

gbritnell

For many years I've had a project in mind to build a Ford flathead V-8 engine. The unique thing about the Ford flathead is that the exhaust runners ran through the water jacket and out the side of the block. Actually this was not a good idea as the extra heat from the exhaust added to the cooling woes of this particular engine. That being said I still wanted to try and build one.

For you fellows who follow my work know I scratch build all of my models from bar stock so after many hours of layouts and drawings I just couldn't come up with a way of fabricating this type of engine from solid. The next plan was to make patterns and coreboxes. I had heard from someone that the old flatheads used 23 cores in the casting process. Having come from a Ford foundry where we cast all types of engines at first I couldn't fathom why this engine would use that many cores. A 302 V-8 engine uses 10 cores and 2 molds, cope and drag. Here again after many hours of layouts and drawings I can now understand why they used so many cores.

Now I've put countless hours into engine and model building but to make all of the coreboxes and patterns required for this engine just seemed a little over the top. I had to ask myself if I really went ahead and made them all and took them to a foundry for casting what would be the cost of making all those cores and casting an engine. Furthermore what would happen if some of the coreboxes go lost or damaged.

It was time for an entirely new game plan! I still wanted to build a flathead but the Ford type was out of the question so the next best thing is the Cadillac design. The difference in this engine compared to the Ford is that all the ports, intake and exhaust, come out of the top of the block. There are castings out there for this type. They are for the Challenger V-8 that Cole's sells but here again I like to make my own engines so it was back to the drawing board.

I have the rough Cad drawings made and have converted them into a solid model. I'm presenting them here for your perusal.

With winter just around the corner, I know it's only July but with the way time flies it'll be here in no time so I'm getting a head start on the project.

gbritnell