-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A little advice on first prints

- Thread starter GunsOfNavarone

- Start date

- Joined

- Feb 5, 2020

- Messages

- 117

I'm not familiar with crealities slicer. However, although slicer's may not "control" retraction, slicer's most certainly can and do generate gcode to over ride the firmware settings.  . In fact, given that different material and types of prints require different retraction settings, it's the best way to adjust retraction. Then after you've found settings that work you can save them to firmware. You'll still likely be tweaking them often though.

. In fact, given that different material and types of prints require different retraction settings, it's the best way to adjust retraction. Then after you've found settings that work you can save them to firmware. You'll still likely be tweaking them often though.

In the reading I've done on the ender 5, many people have had issues with their Bowden tube couplings. Any play in the couplings can cause issues with retraction. If the creatlity slicer has a profile for your printer and you are using it, I would look at your Bowden tube and couplings. Your last pic shows a ton of stringing which seem far in excess of what you would see with the proper printer profile, unless there was another issue.

Have you calibrated your extruder?

In the reading I've done on the ender 5, many people have had issues with their Bowden tube couplings. Any play in the couplings can cause issues with retraction. If the creatlity slicer has a profile for your printer and you are using it, I would look at your Bowden tube and couplings. Your last pic shows a ton of stringing which seem far in excess of what you would see with the proper printer profile, unless there was another issue.

Have you calibrated your extruder?

Last edited:

- Joined

- Feb 5, 2020

- Messages

- 117

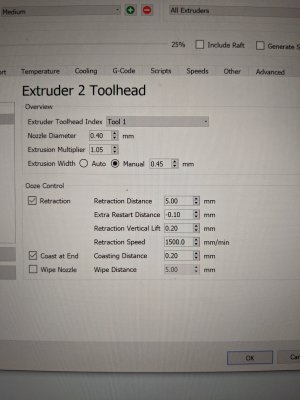

Here's a pic of my cr-x retraction settings. Different slicer's use different names for things, but it might help give you an idea of what I'm talking about. Also, my printer isnt the same as yours, but it is a Bowden setup so it might help. Again though, creality should have a profile for your printer and I would be hard pressed to believe their factory profile is as far off as you're experiencing without some other hardware issue.

Sadly, I'm working N. Of the Arctic Circle at the moment and limited to only 450MB of data per day or I'd install creality's slicer and try it out.

Sadly, I'm working N. Of the Arctic Circle at the moment and limited to only 450MB of data per day or I'd install creality's slicer and try it out.

Attachments

Last edited:

- Joined

- Jan 7, 2016

- Messages

- 3,273

Holy crap, that is a ton of retraction acruxksa. The Prusa is not a Bowden setup and it definitely shows there. My retract setting is 0.8mm on my Prusa, just for comparison. I have never had a Bowden setup so this would be new territory for me.

North of the Arctic Circle huh... Even for you, that is a ways away from home.

North of the Arctic Circle huh... Even for you, that is a ways away from home.

- Joined

- Jun 26, 2018

- Messages

- 1,733

@acruxksa don't worry about downloading a slicer....I appreciate it, but this is just going to be a job of picking peoples brains, watching YT, And running tests. I did calibrate the extruder, it was only putting out 91.x mm of filament on a 100mm run. I'm gonna try to run a retraction test part, but right now I'm not sure how to diagnosis what it shows or what to change. Trial and error is cumbersome as its not a quick change or quick result. Hopefully these problems start to clear up soon!

- Joined

- Jan 7, 2016

- Messages

- 3,273

Yeah buddy. Sumtinwong. As others have pointed out, it is either within the tube or in the retraction settings. At least give that a shot.Even with all the calibration so far....is this settings within the Slicer? 1.75mm PLA @200* these strings should not be there...

Try some small test parts. They print much faster so you can check the results of the changes faster.

www.thingiverse.com

www.thingiverse.com

I use this frequently. It's about a 10 minute print at my more common settings. But it covers the basics. I also destructive test them to check layer adhesion. Squeeze with pliers and see how it breaks. If the break follows the layer lines or you can pull it apart without tools, add about 5 degrees to the extruder at a time until you have good layer bonds. Keeping it lower will help strings and other problems, but you need enough to get the plastic to fuse.

Easy Material Settings Calibration Piece by A_R_B

I was searching for something to easy help me with the filament material settings. Nothing big or with long waiting times. For that a long list of things is available, but just for trying the most important settings as temperatures, flows, speed, layer height, etc. Here is it: print time is...

I use this frequently. It's about a 10 minute print at my more common settings. But it covers the basics. I also destructive test them to check layer adhesion. Squeeze with pliers and see how it breaks. If the break follows the layer lines or you can pull it apart without tools, add about 5 degrees to the extruder at a time until you have good layer bonds. Keeping it lower will help strings and other problems, but you need enough to get the plastic to fuse.

- Joined

- Jan 21, 2013

- Messages

- 868

@GunsOfNavarone Your using a bowden feeder to your hotend, and that means the filament buckles a little inside the tube as you print, creating a spring that keeps pressing filament thru the extruder even when you're not feeding it. Looks like it may be Capricorn tubing which helps, but it can still happen. With a bowden, retract distances of 5mm is common and up to 7mm is not unusual. start with a retract speed of 25mm/s. Too fast, and the filament breaks away from the melted portion, and doesn't do any good. Travel speed also helps to break the string by moving the head faster than the plastic can stretch. With PLA you should be able to lower the temp as well, but that depends on the brand, nozzle size, and how fast you want to print.

- Joined

- Jun 26, 2018

- Messages

- 1,733

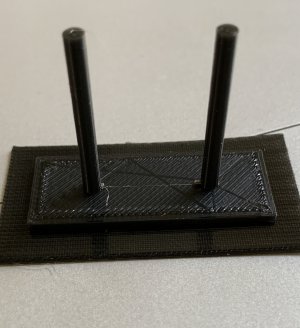

So update.... I did find that the drive motor side of the Bowden tube was missing a spacer that the extruded side did have. It gave it about 2mm of slack which the retraction appears to be set at 1.5, so it wasn’t getting that retraction. (Good call on the Bowden tube) I did the retraction test part...see picture. I don’t know what I’m looking for...it appears fine?

I also did the quick cal pieces, again, I assume they are ok. I see issues with larger pieces & I just can’t get good BED ADHESION....not sure what that cause is. I tried to do the “sqiushy boxes” calibration, but fine tuning the levelers did nothing for adhesion. (It came off mostly pretty easy. The retraction test prior to fixing Bowden tube is the picture of just a platform.

I also did the quick cal pieces, again, I assume they are ok. I see issues with larger pieces & I just can’t get good BED ADHESION....not sure what that cause is. I tried to do the “sqiushy boxes” calibration, but fine tuning the levelers did nothing for adhesion. (It came off mostly pretty easy. The retraction test prior to fixing Bowden tube is the picture of just a platform.

Attachments

-

6275B9FA-708D-4C44-B666-CB4CE93AC3C0.jpeg818 KB · Views: 188

6275B9FA-708D-4C44-B666-CB4CE93AC3C0.jpeg818 KB · Views: 188 -

37C1EF42-45F7-44F6-B243-335F29482881.jpeg280.8 KB · Views: 172

37C1EF42-45F7-44F6-B243-335F29482881.jpeg280.8 KB · Views: 172 -

8BE49095-F24E-48F9-9DFF-F837B74CA3D2.jpeg162.6 KB · Views: 161

8BE49095-F24E-48F9-9DFF-F837B74CA3D2.jpeg162.6 KB · Views: 161 -

ED79859D-64FD-4726-B0C0-89D9D84DE9AF.jpeg229 KB · Views: 161

ED79859D-64FD-4726-B0C0-89D9D84DE9AF.jpeg229 KB · Views: 161 -

A8F0DCD4-9F90-47DE-A745-25BD212B6941.jpeg972 KB · Views: 173

A8F0DCD4-9F90-47DE-A745-25BD212B6941.jpeg972 KB · Views: 173 -

13447DD6-37DB-42EA-B85F-321AC053FB43.jpeg1.1 MB · Views: 157

13447DD6-37DB-42EA-B85F-321AC053FB43.jpeg1.1 MB · Views: 157