- Joined

- Feb 8, 2014

- Messages

- 11,144

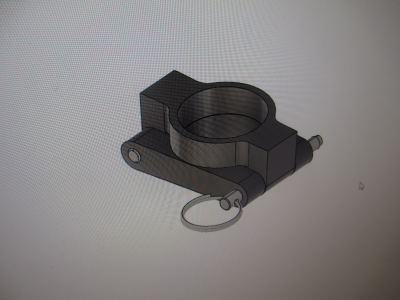

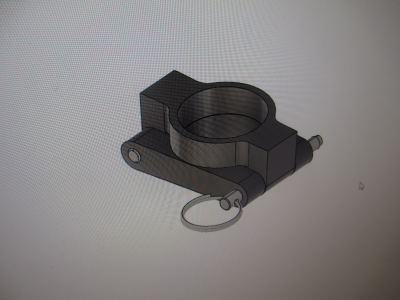

These are some hinges for what we call break down tubes for our truck camper stabilizer product. These are really for a particular camper model that has limited storage space, so the hinge allows it to fold for storage.

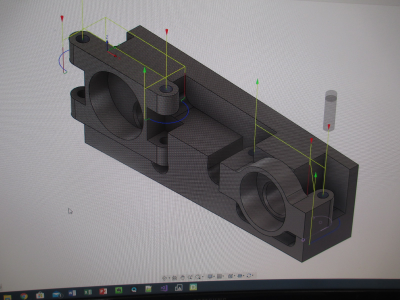

Sorry about the picture quality, I just photographed the screen

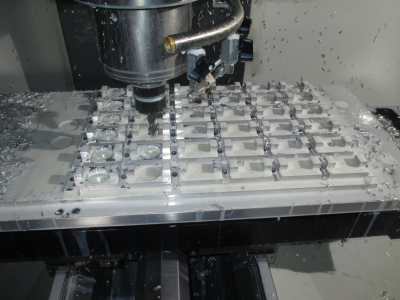

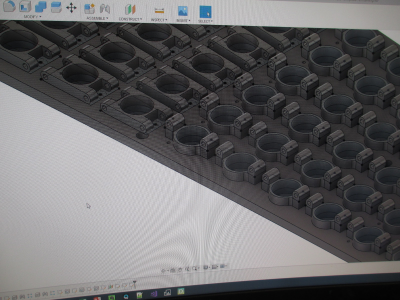

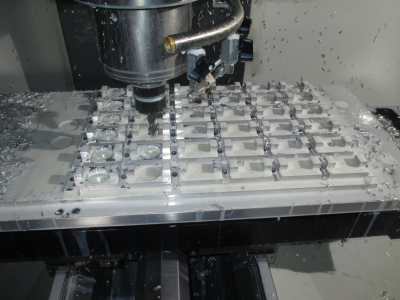

And the layout for machining. The raw stock bolts down to the fixture plate then is machined into the form you see in the next pictures.

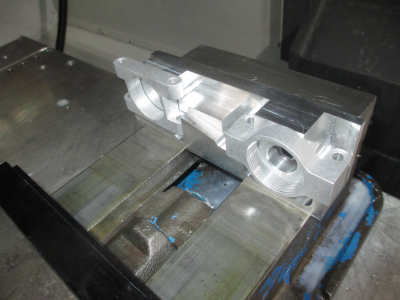

The raw stock for the piece with the two protrusions is 1x1.75 6061 bar stock. The flat pieces are made from 1/2 x 14 6061 plate. Haven't made any of the flat pieces yet.

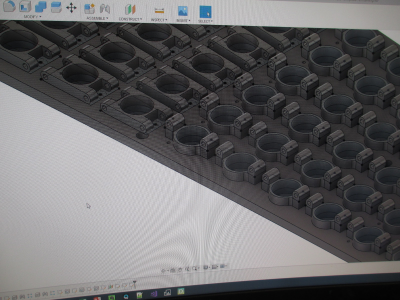

And 36 pieces in process. About 45 minutes from raw stock to roughed out as below in the next picture.

And a close up of the roughed out pieces. The thread is 1 1/2-16, threaded with a thread mill. We chose 16 TPI for the best compromise between thread strength and thread depth. We only have so much wall thickness to work with.

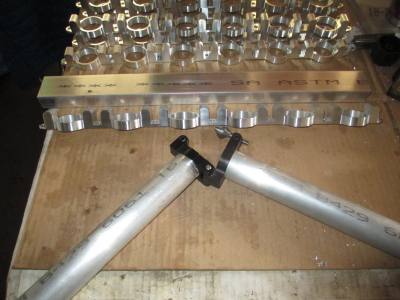

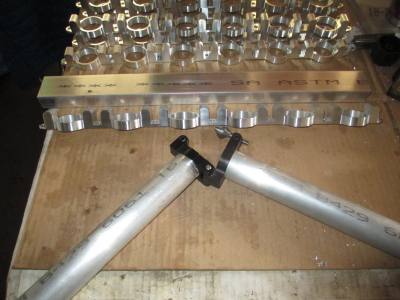

And a wider view. And an old style hinge with tubes screwed in shown. Current production is the new style, easier to manufacture. These will be cut apart and finished in a second operation. I'll post the second opp when we get to it. The raw stock is shown for comparison.

And this is how we thread the tubes.

Sorry about the picture quality, I just photographed the screen

And the layout for machining. The raw stock bolts down to the fixture plate then is machined into the form you see in the next pictures.

The raw stock for the piece with the two protrusions is 1x1.75 6061 bar stock. The flat pieces are made from 1/2 x 14 6061 plate. Haven't made any of the flat pieces yet.

And 36 pieces in process. About 45 minutes from raw stock to roughed out as below in the next picture.

And a close up of the roughed out pieces. The thread is 1 1/2-16, threaded with a thread mill. We chose 16 TPI for the best compromise between thread strength and thread depth. We only have so much wall thickness to work with.

And a wider view. And an old style hinge with tubes screwed in shown. Current production is the new style, easier to manufacture. These will be cut apart and finished in a second operation. I'll post the second opp when we get to it. The raw stock is shown for comparison.

And this is how we thread the tubes.