- Joined

- Dec 3, 2017

- Messages

- 1,920

If you have a drawbar collet closer, do you leave it set up all the time? I have no experience with them. At one shop I worked at, the machinist only ever had it installed when he needed to use collets. At my current employer, I’ve noticed they’ve left the drawtube loaded all the time. To be clear, the machine has a 3 jaw on it 99% of the time.

Are there pros and cons to this? Or is it machine dependent?

I very much dislike collet chucks. But have stayed away from drawtube setups, because I also very much dislike finagling with attachments that aren’t mostly already installed. Plus the thing looks complicated enough that pieces of it could grow legs if it didn’t stay in one place.

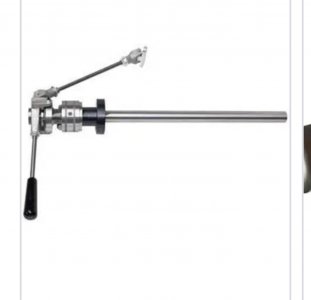

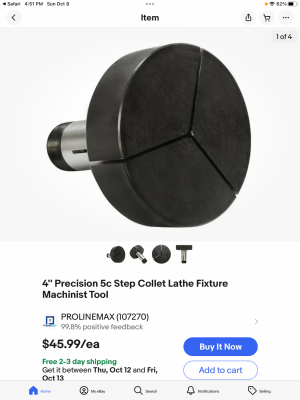

I’m talking specifically about the type of closer pictured.

The only thing I can imagine, that leaving it installed all the time does that some would dislike is shrink the spindle through hole capacity. But I’ve got a 3/4” spindle capacity, and most of my work isn’t that small to begin with.

Are there pros and cons to this? Or is it machine dependent?

I very much dislike collet chucks. But have stayed away from drawtube setups, because I also very much dislike finagling with attachments that aren’t mostly already installed. Plus the thing looks complicated enough that pieces of it could grow legs if it didn’t stay in one place.

I’m talking specifically about the type of closer pictured.

The only thing I can imagine, that leaving it installed all the time does that some would dislike is shrink the spindle through hole capacity. But I’ve got a 3/4” spindle capacity, and most of my work isn’t that small to begin with.