- Joined

- Apr 1, 2015

- Messages

- 76

I had posted these pics in another thread but, rather then hijack that one I will make on of my own.

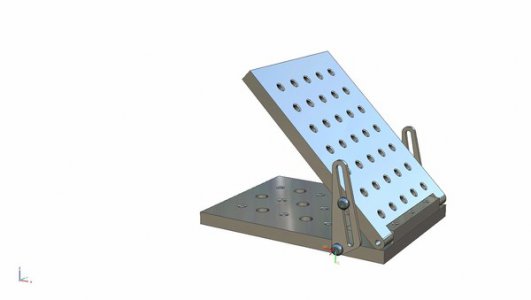

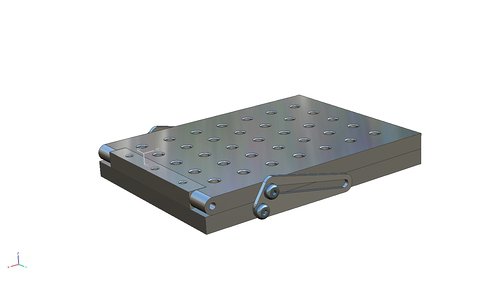

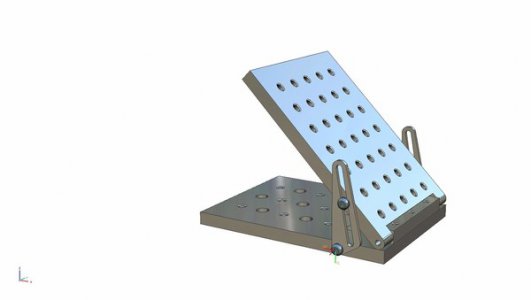

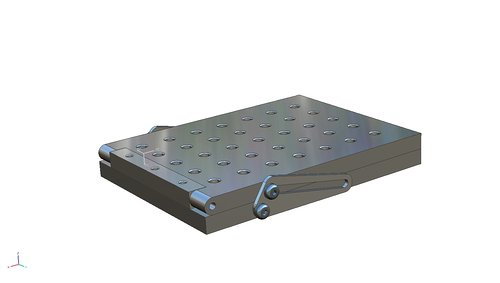

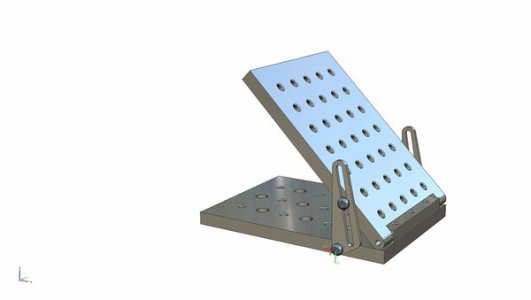

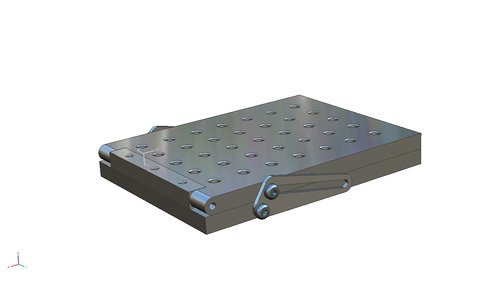

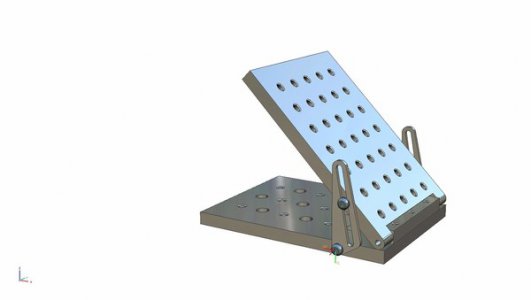

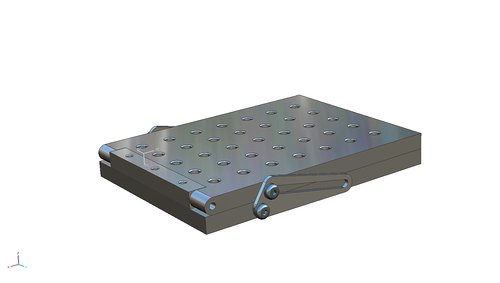

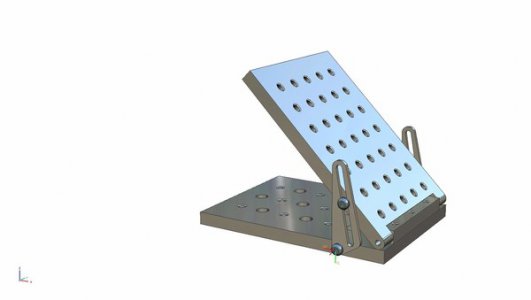

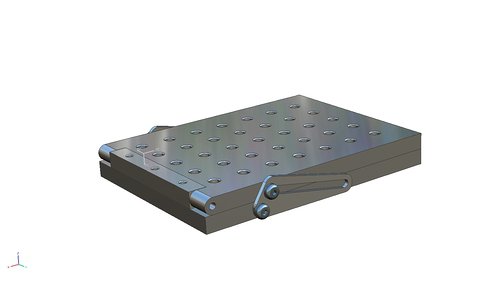

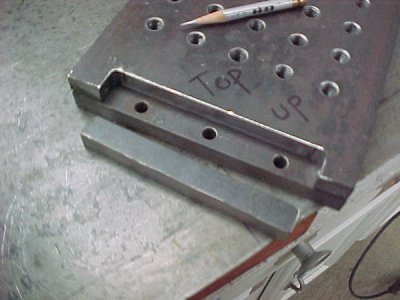

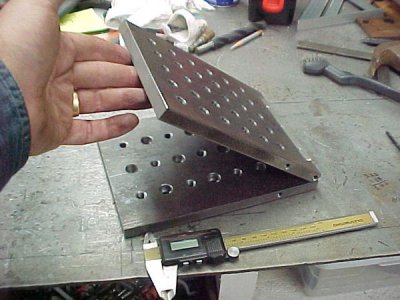

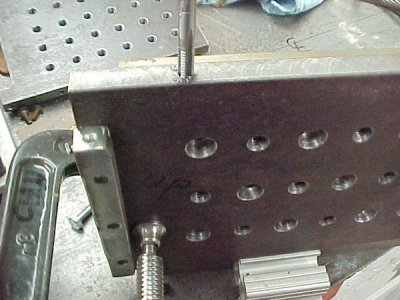

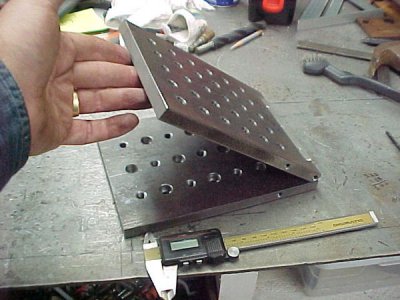

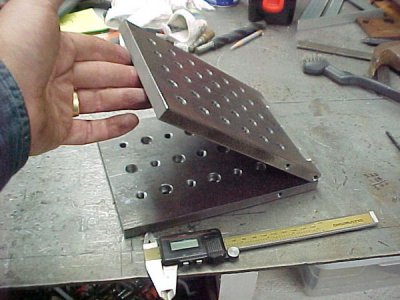

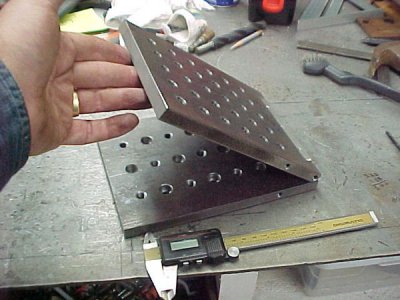

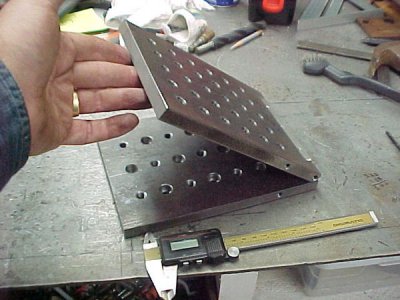

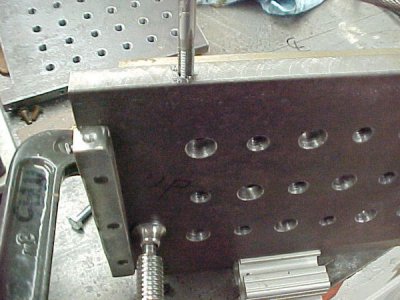

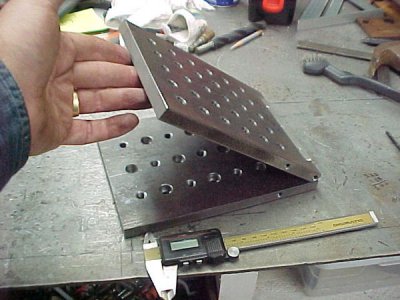

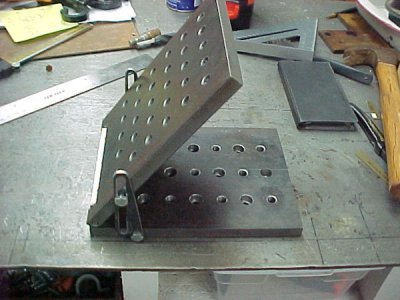

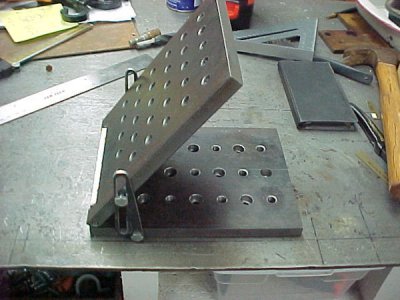

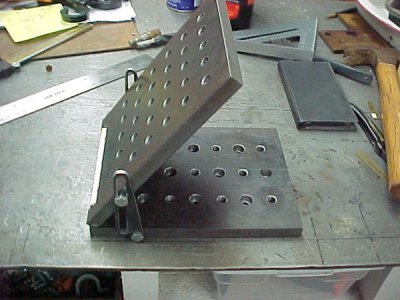

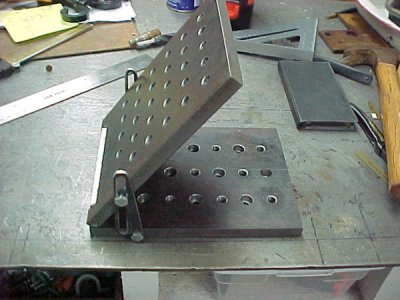

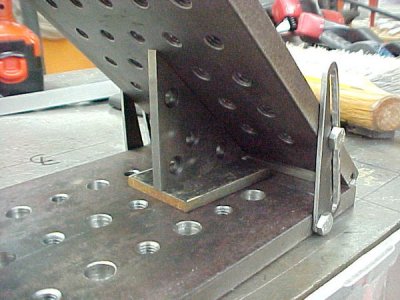

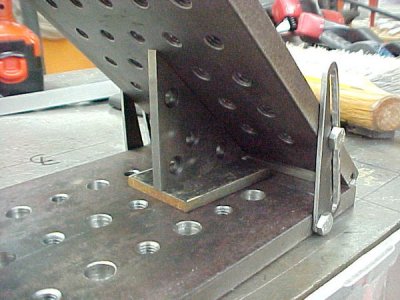

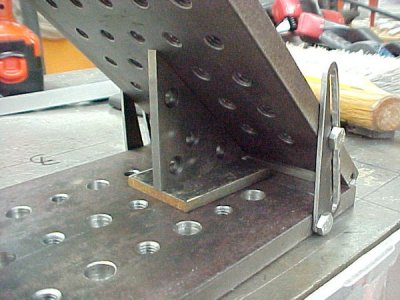

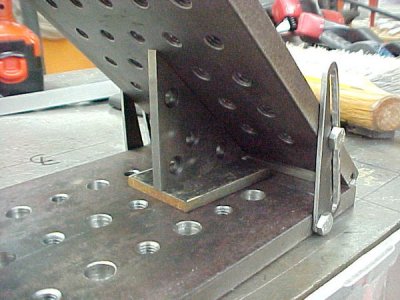

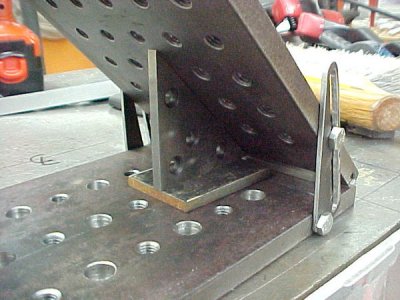

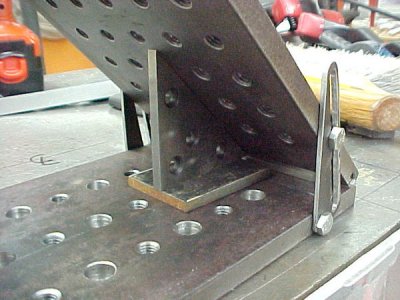

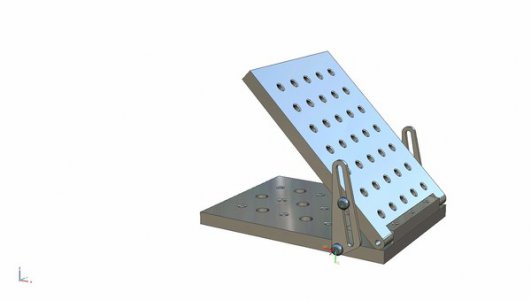

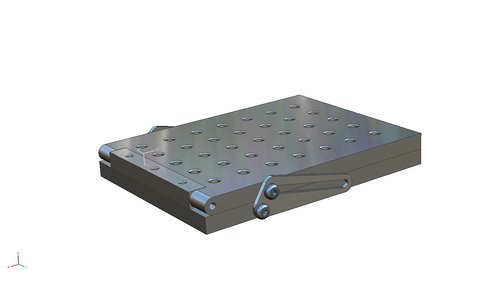

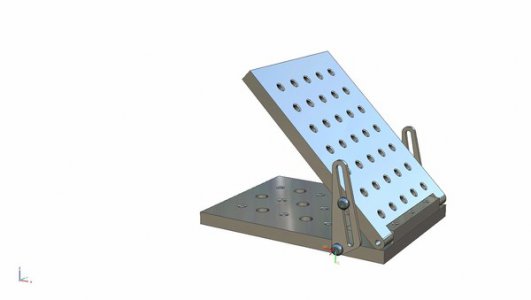

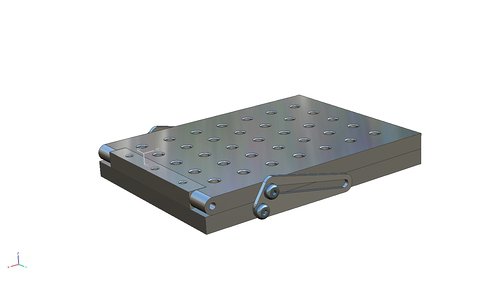

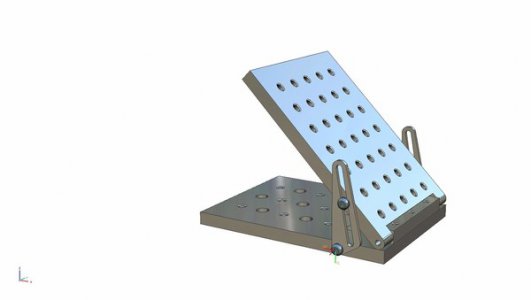

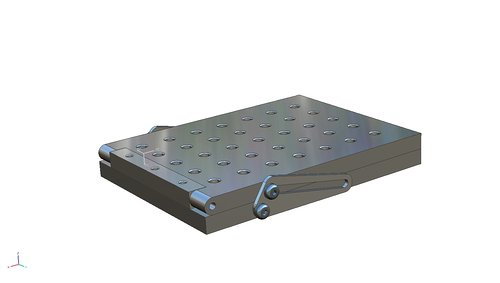

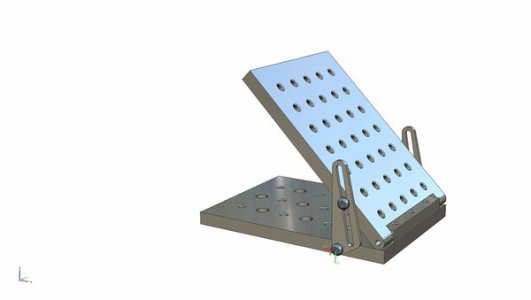

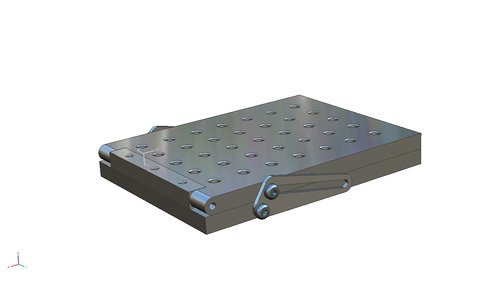

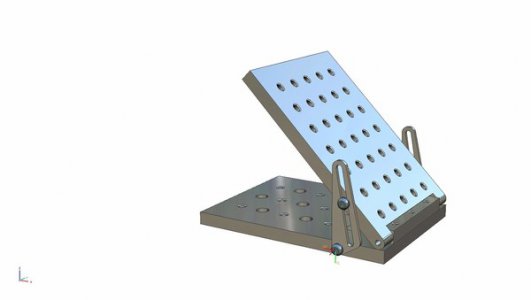

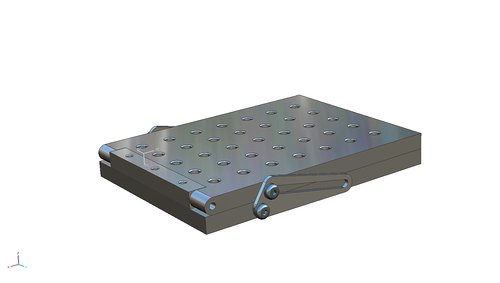

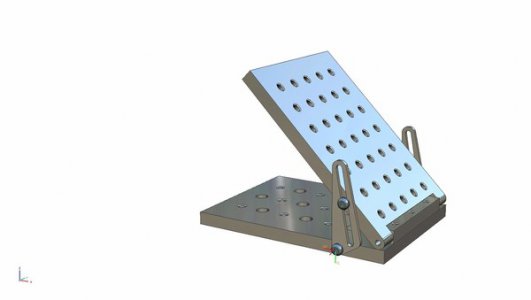

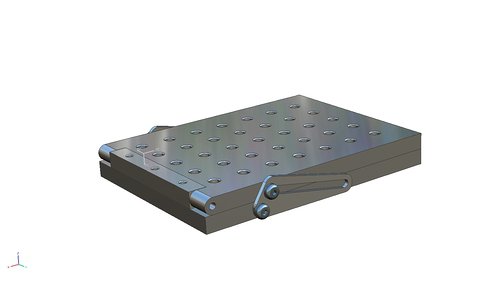

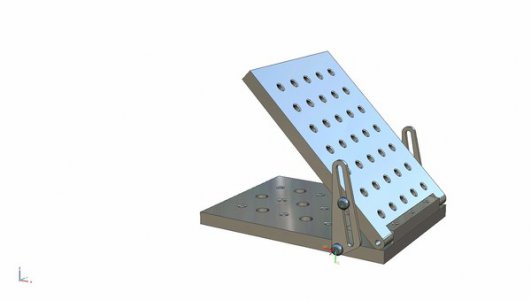

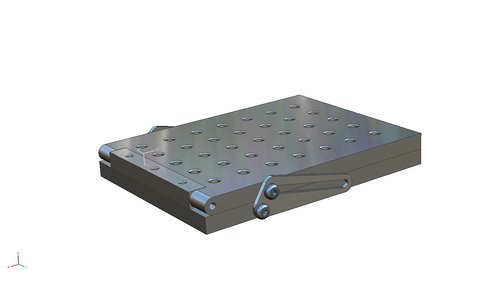

Here are some screen shots of my version of Fred Giesler's design that was in the Dec. '95 PIM. I made it a bit bigger and went with 1/2" plate instead of his 3/8th's but it is essentially his design.

My plates are 6 x 8 and I designed the side guides to allow the table to go to 90* verticle also.

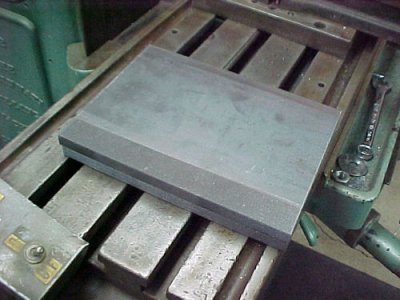

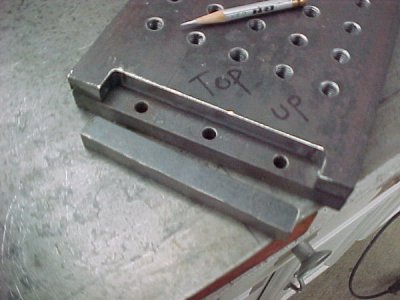

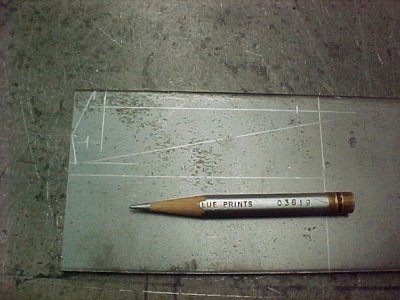

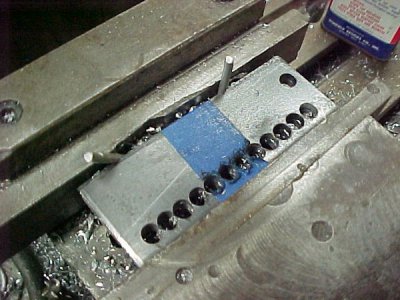

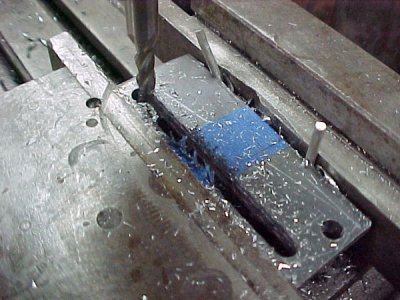

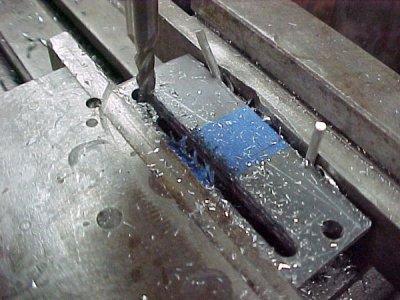

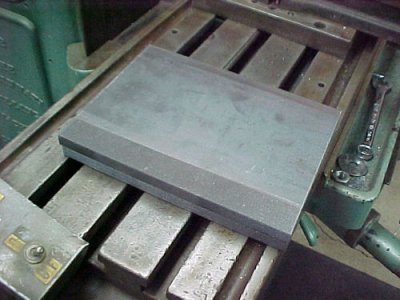

I have the plates cut to size and squared up but decided to put a DRo on the FrankenMill to make drilling the holes a little more fun rather then a chore...

Mark

Here are some screen shots of my version of Fred Giesler's design that was in the Dec. '95 PIM. I made it a bit bigger and went with 1/2" plate instead of his 3/8th's but it is essentially his design.

My plates are 6 x 8 and I designed the side guides to allow the table to go to 90* verticle also.

I have the plates cut to size and squared up but decided to put a DRo on the FrankenMill to make drilling the holes a little more fun rather then a chore...

Mark