- Joined

- May 10, 2012

- Messages

- 995

I decided some time ago that I wanted an RV of some sort. After some thought, I decided on a truck camper. There is a small problem, though. Truck campers (and specifically the one I bought) look something like this:

And my truck looks like this:

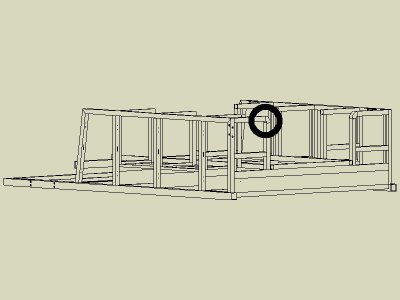

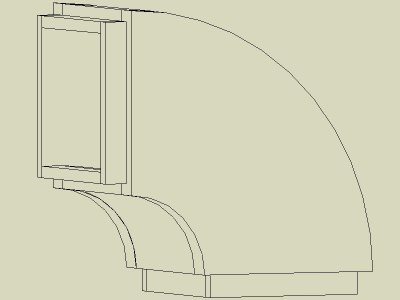

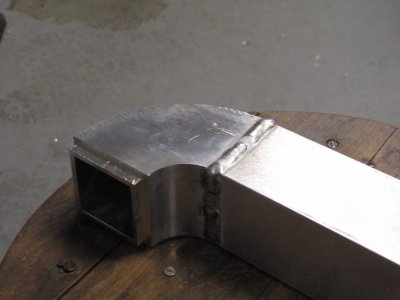

Which called for a solution, the one I came up with will look like this when it's done:

This subframe will allow the camper to go all the way to the front of the 10 ft bed, as well as supporting and attaching the camper to the bed through the stake pockets. It also provides quite a bit more storage where the wheel well holes are on the camper. More to follow, wife wants me to go somewhere now.

And my truck looks like this:

Which called for a solution, the one I came up with will look like this when it's done:

This subframe will allow the camper to go all the way to the front of the 10 ft bed, as well as supporting and attaching the camper to the bed through the stake pockets. It also provides quite a bit more storage where the wheel well holes are on the camper. More to follow, wife wants me to go somewhere now.