HF-Start - Some notes on how it works

What I mean is - what I have understood of it so far.

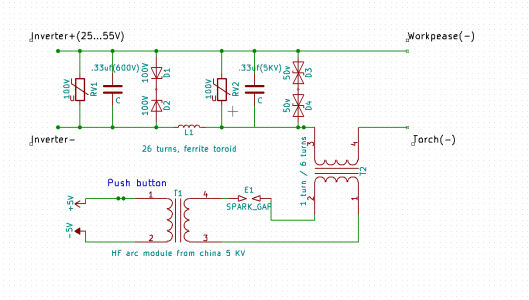

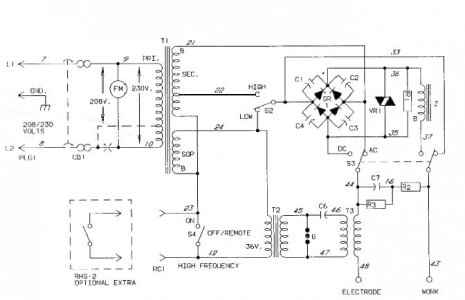

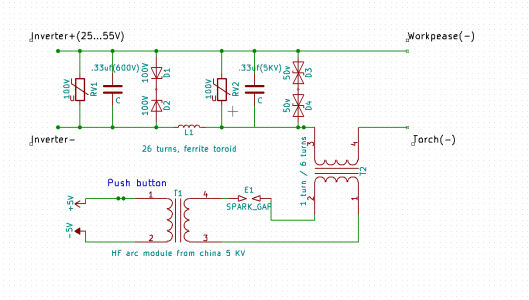

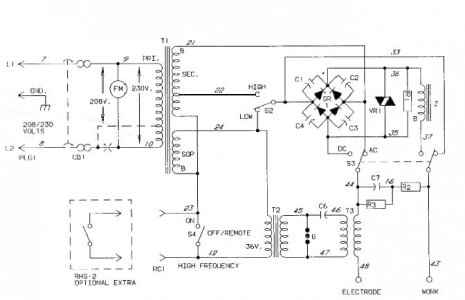

Even without being an electronics expert, consider the following typical circuit fragments. I will try a general explanation, but if electronics is not your thing, suffice to say that one circuit is all about stopping HF-start stuff from getting back and hurting the inverter electronics. Both circuits show the way HF start is added in series with whatever the welder produces, and only does it's thing briefly.

In both cases, just notice the connections to the torch, and follow one lead back. See how it encounter's a thing with

coils.

That RF coil, part of an RF transformer, is made from big fat conductors, and is the way to introduce the high frequency start

in series with the the welder voltage. It is only effectively there briefly. When not introducing radio frequency voltages, the RF coil looks like a bit of fat cable coiled up, not affecting the regular weld currents in any way.

Here is a picture of the bits..

Notice two white wires going into the coupling coil. They are for the RF resonant oscillator generating the radio-frequency voltage.

It might be air-cored, or it might have a ferrite rod up it - I can't tell.

- - - - - - - - - -

Many RF generators are the crudest possible, made exactly like the early Marconi spark transmitters for ships, using a spark gap with an induction coil. Many DIY designs just use a spark plug to provide the gap. Every splat sets the circuit ringing at radio frequency, which dies out, until the next spark. The spark seems continuous, while HF start is on, but it is really a series of separate sparks.

Notice the first circuit HF Arc Starter. All the bits to the top left are not the whole inverter, but a chunk of circuit devoted only to stopping RF and overly high voltages getting back into the inverter. D3 and D4 together will limit anything across them to 100V. Varister RV2 will short out anything over 100V.

The capacitors and inductor L1 form a low pass filter, blocking any RF. L1 needs to be made of thick stuff. The whole act is repeated upstream of L1, limiting voltage to 100V, with a belt-n-braces D1 with D2, at 200V, just in case the other fails.

The entire circuit fragment shows an extremely determined and elaborate provision to absolutely stop any high voltage shenanigans introduced by the HF coil transformer T2 from getting back into the inverter. It is a huge and deliberate protection circuit.

- - - - - - - - -

The second circuit is a "buzz box" welder circuit in it's entirety. No high tech IGBT switcher pulsed and arc current controlled waveforms here. It's just a transformer! OK then - it also has a bridge diode rectifier to deliver a DC option. The choke inductor "Z" blocks radio frequency energy getting back to hurt the bridge rectifier 4 diodes silicon rectifier "SR". Capacitors C1-C4 shunt any remaining RF. VR1 is a overvoltage protection device. C7, R2, and R3 are a snubber circuit, also to damp unwanted ringing. T3 is the gadget we are looking for. It's the series coupling RF transformer. Notice the spark gap G, and the step-up transformer T2. When the AC voltage is high enough to cause the spark to jump, the spark completes the circuit C6 and the inductance of T3, which rings at radio frequency.

So - anyone contemplating "adding" a HF start needs at least to understand exactly what they are doing, and how it works. That said, the bits are pretty cheap, perhaps amounting to 5% of a whole welder cost. I am unimpressed by all versions of "spark plug gap" oscillator I have seen so far. Those featuring a proper RF oscillator will interest me more.

In at least one YT video, the guy adds a sparkplug version to the welder, which initially messes it up, though it survives. He says it "seems to cancel" the welder. He "gets it to work" by introducing another spark gap in the lead in his handle add-on. Actually, it was "working" after a fashion, perhaps from a single little spark at the electrode. I DO NOT advise attempting anything like this. It's still too easy to damage a $800 welder this way.