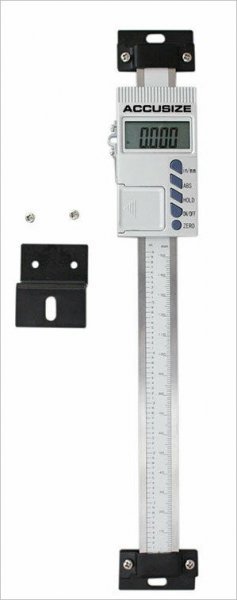

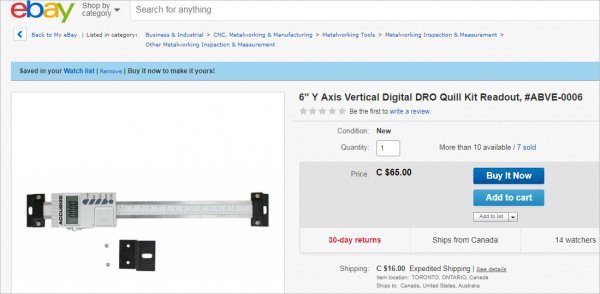

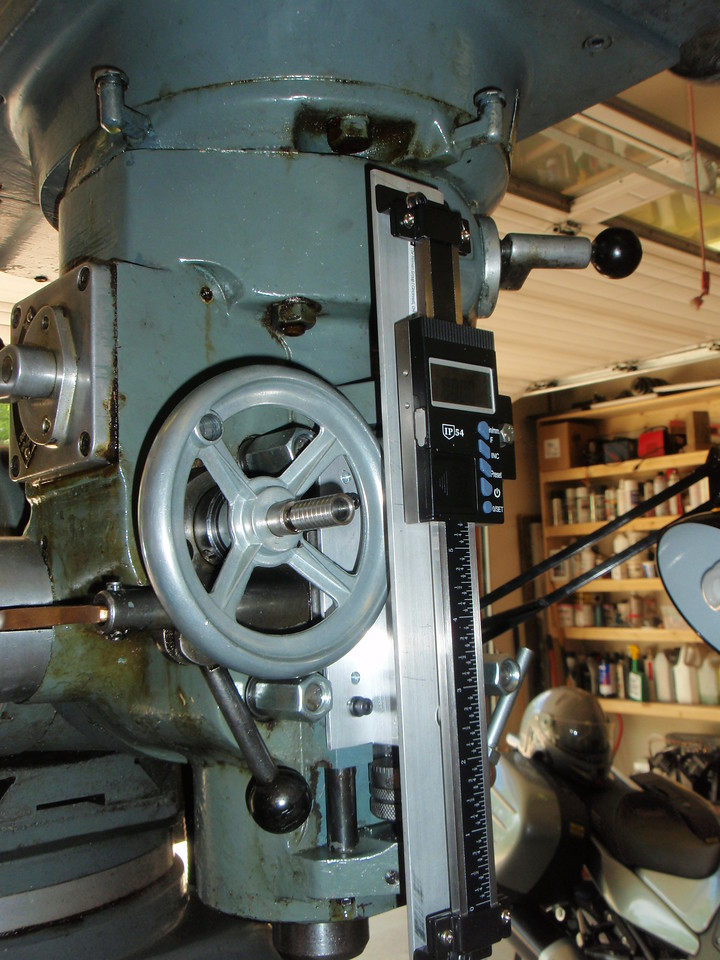

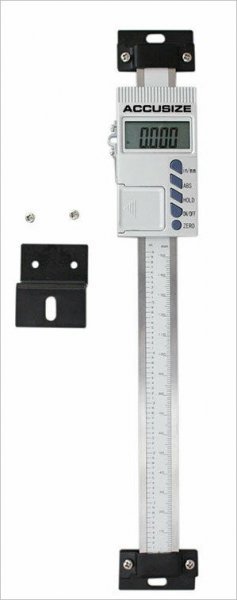

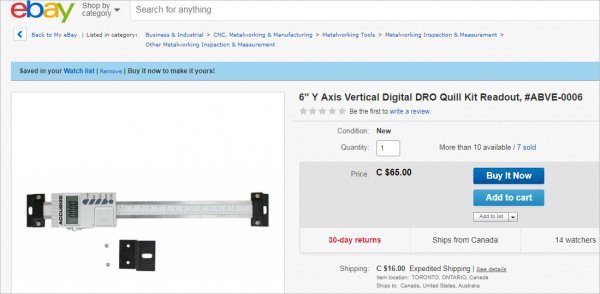

Just wondering if any of you have installed this quill DRO (or I suspect its offshore lookalikes). Are they battery gobblers like many offshore digital calipers?

https://www.ebay.ca/str/Canada-Quality-Machine-Shop?_trksid=p2047675.l2563

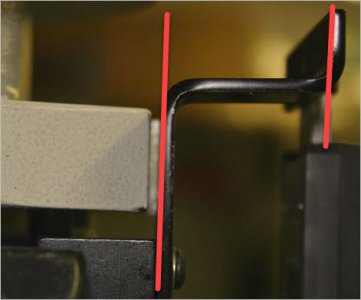

Sadly my Mitutoyo has suddenly got crazy friction sticky recently after only a few months light use. I though I was having quill issues, it felt gritty. I removed it fully expecting a chip had migrated in there. No chip. Everything appear to be normal. Yes, its a real Mitutoyo not a copy, purchased from KBC. It was installed with TLC perfectly aligned. I slid the encoder bar out of the unit, examined the brass gib strip. There are 2 sets of opposing brass screws inside. One set rides on the encoder bar but you dont see them on outside of case. I noticed some light scratches on that side of the bar. The other set pushes on removable brass gib strip & they are painted red with loctite (factory adjusted). I didn't touch either, just gave the inside it a light blow of air & re-assembled. Same deal, gritty friction. Paid to much for this to have issues & this is coming from a Mitutoyo fan boy. So I will see what can be done through warranty.

Meanwhile looking at something cheaper to replace. Or who knows if I like it might stay with it. Its something I want & need but don't use often.

https://www.ebay.ca/str/Canada-Quality-Machine-Shop?_trksid=p2047675.l2563

Sadly my Mitutoyo has suddenly got crazy friction sticky recently after only a few months light use. I though I was having quill issues, it felt gritty. I removed it fully expecting a chip had migrated in there. No chip. Everything appear to be normal. Yes, its a real Mitutoyo not a copy, purchased from KBC. It was installed with TLC perfectly aligned. I slid the encoder bar out of the unit, examined the brass gib strip. There are 2 sets of opposing brass screws inside. One set rides on the encoder bar but you dont see them on outside of case. I noticed some light scratches on that side of the bar. The other set pushes on removable brass gib strip & they are painted red with loctite (factory adjusted). I didn't touch either, just gave the inside it a light blow of air & re-assembled. Same deal, gritty friction. Paid to much for this to have issues & this is coming from a Mitutoyo fan boy. So I will see what can be done through warranty.

Meanwhile looking at something cheaper to replace. Or who knows if I like it might stay with it. Its something I want & need but don't use often.