- Joined

- Apr 30, 2015

- Messages

- 11,302

You could do a light press fit with epoxy or loctite, it will stay put

-Mark

-Mark

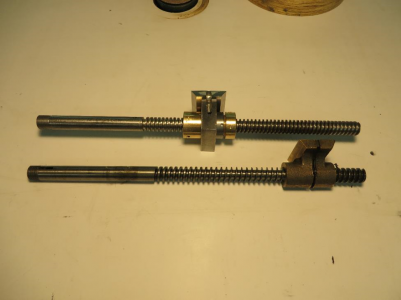

Kurt vises are not acme thread.

In use acme threads have lower friction than 60 degree threads and acme work better in the presence of debris or dust.

Russ

Remember, since this is going to be a leadscrew for a vise, you're going to need LEFT HAND threaded versions of both.

Left hand would be standard, but if you can live with your vise going "the wrong way" when you try to use it, then you can use RIGHT HAND threads