- Joined

- Oct 17, 2018

- Messages

- 922

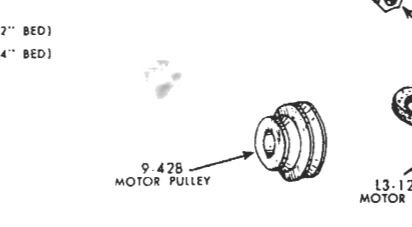

In order to easily get more speeds from my Atlas Craftsman 101.07403 I'd like to change out the single groove pulley on the motor shaft for a double groove pulley. I currently have 16 speeds ranging from 15 RPM to 714 RPM. To get more speeds, I have to unbolt and move the motor over so the single groove on the motor pulley aligns with the other, smaller groove on the spindle pulley. Having a 2 groove pulley on the motor shaft would allow me to merely change belts from one spindle pulley to the other.

I could make one or buy one. The pulley would need to be about 1.75" OD to match what I have now. These are proving hard to find. I did find a 2.25" OD one. Are they hard to make? Could I use aluminum?

This is not a stock/original motor. It has a 1/2" shaft. It has two speeds; high is twice the speed of low.

Thoughts?

I could make one or buy one. The pulley would need to be about 1.75" OD to match what I have now. These are proving hard to find. I did find a 2.25" OD one. Are they hard to make? Could I use aluminum?

This is not a stock/original motor. It has a 1/2" shaft. It has two speeds; high is twice the speed of low.

Thoughts?