- Joined

- Nov 6, 2012

- Messages

- 127

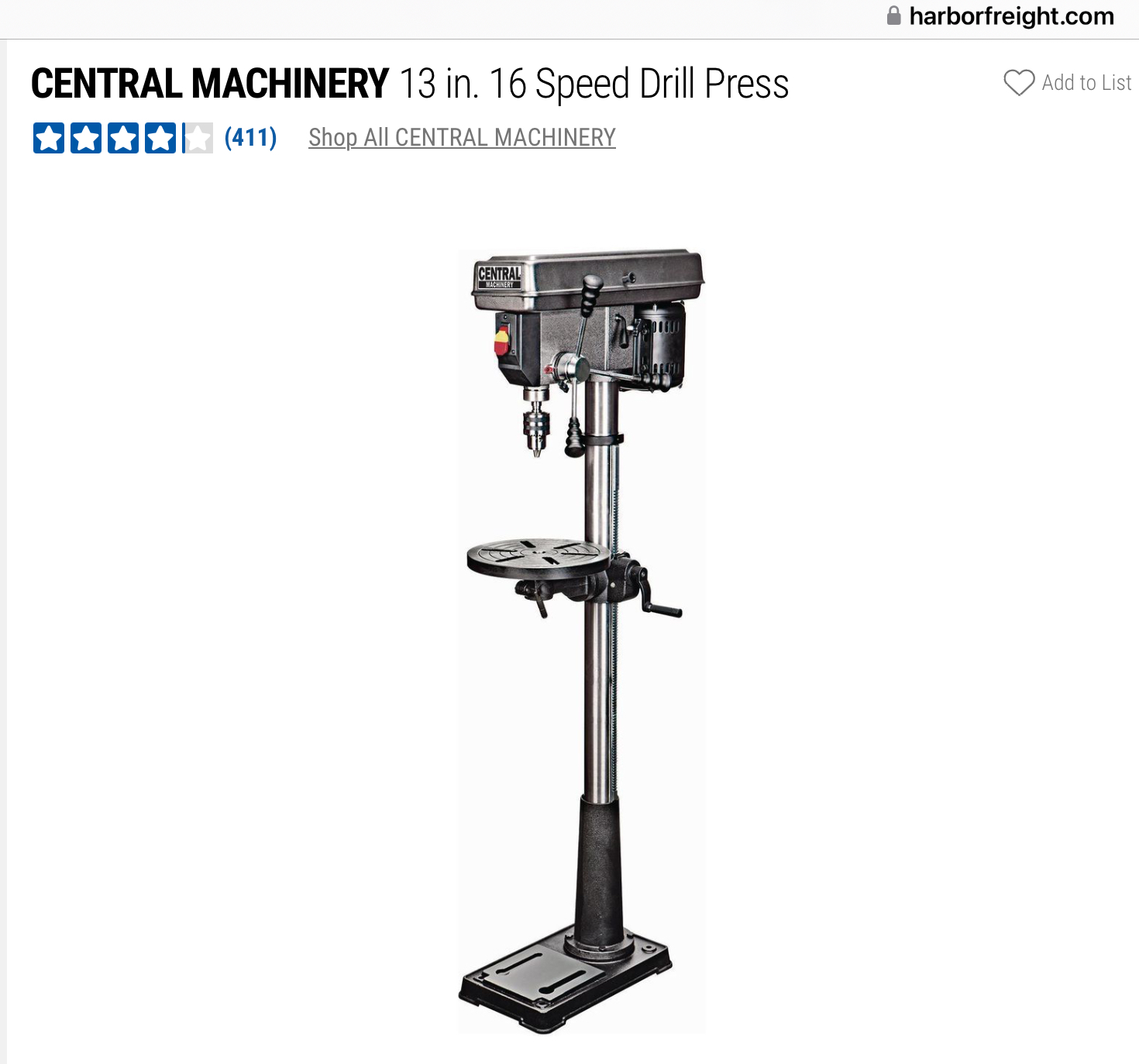

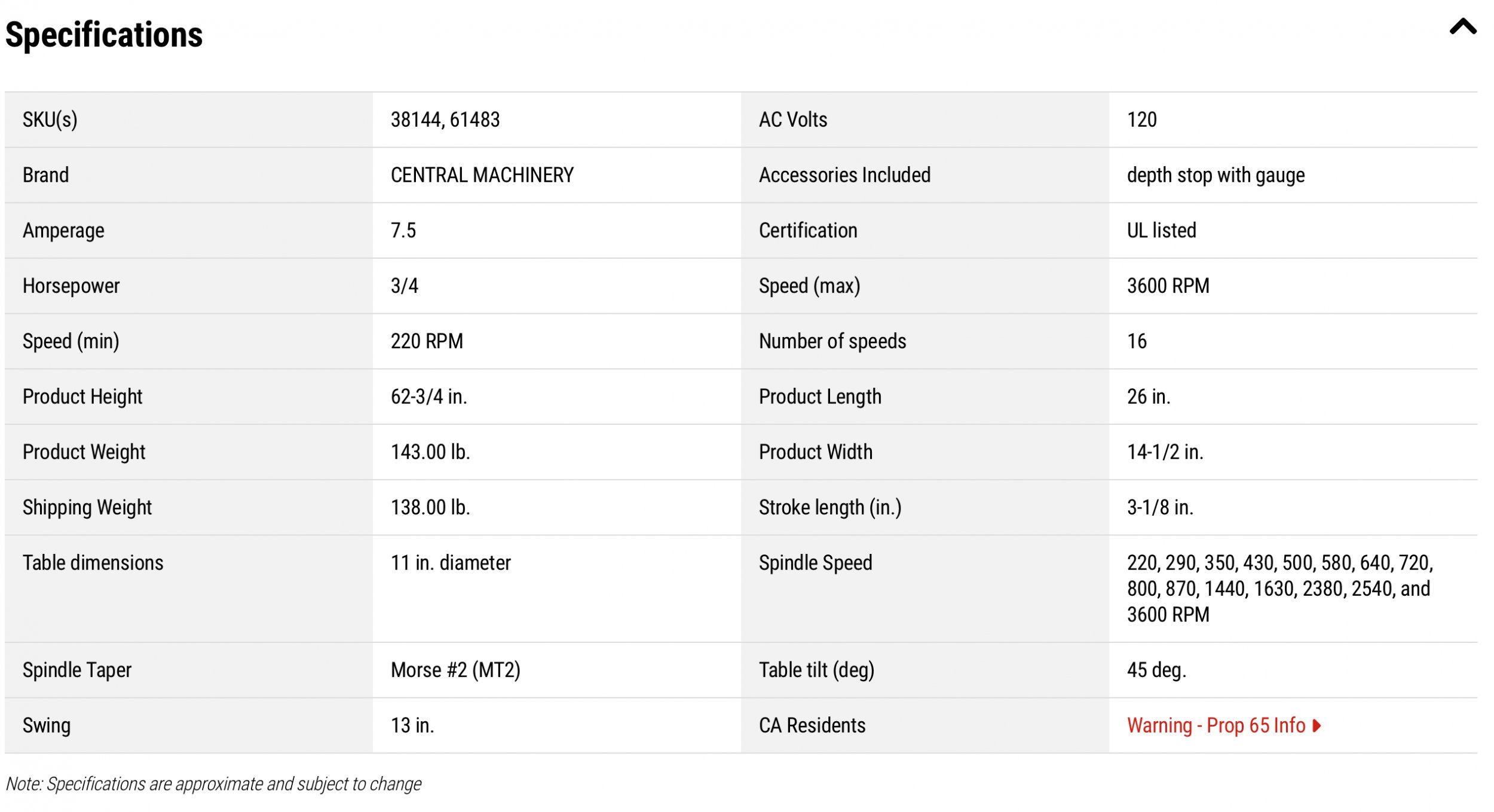

What makes for an adequate hobbyist Drill Press to add to a LMS Mini Mill and Mini Lathe? I’ll start with a budget example from Harbor Freight, on clearance for $209. Where would the machine be limiting or inadequate? I have no particular aspirations in mind - just making tooling and fixtures, small engine models, etc. I’d like to buy “adequate” first and upgrade if needed, but not regret a bad purchase.

www.harborfreight.com

www.harborfreight.com

13 in. 16 Speed Drill Press

Amazing deals on this 13In 16 Speed Drill Press at Harbor Freight. Quality tools & low prices.