Very much a beginner. As a simple project I was going to make a wheel marking gauge for woodworking. For the body of the tool I was going to cut a disc from larger brass round stock, joined to a length of thinner round stock. My question is what is the best way for a beginner to join them: pins, threads, bolts,.silver solder? Under normal use a tool like this isn't subjected to much force, but I wanted to machine it attached as of it were one solid piece, which is why I was leaning towards silver soldering. Good idea, bad idea?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice on joining larger pieces of brass

- Thread starter lungfish

- Start date

- Joined

- Mar 25, 2013

- Messages

- 4,617

Do you have a lathe? It would be pretty easy to put a screw in the center for alignment and then solder the pieces together for permanence. You could put it back in the lathe and file off the solder so it looks like one piece.

- Joined

- Apr 30, 2015

- Messages

- 11,329

You could use any of those methods or even epoxy cement like JB weld as long as there is enough surface area to bond

- Joined

- Jul 29, 2014

- Messages

- 2,737

i've really become enamored of press fits. They're trivially easy, look great, and what can be important later, are easy to undo. Pretty much have to have a lathe and some kind of press, vise or big hammer though.

- Joined

- Apr 21, 2015

- Messages

- 582

If you want to impress your friends, cut a slight chamfer around the edge of the mortise and make the pin slightly long but a tight fit into the mortise, then peen the end with a hammer. Finish by filing and sanding the protruding and peened end of the tenon and the parts will look almost welded together.

It’s worth practicing to get a feel for how much of a chamfer is required, but it’s a very satisfying result when done well and not too difficult with brass.

A flat to prevent rotation is best for a peened rivet like this, either a square/rectangular tenon or D shaped is good. Good needle files are your friend.

With a round tenon, you’ll want a press fit even before peening. Even then it may eventually work a little loose and rotate eventually.

No matter the shape of the tenon, you want a shoulder all the way around the rod with a smaller tenon, of course.

It’s worth practicing to get a feel for how much of a chamfer is required, but it’s a very satisfying result when done well and not too difficult with brass.

A flat to prevent rotation is best for a peened rivet like this, either a square/rectangular tenon or D shaped is good. Good needle files are your friend.

With a round tenon, you’ll want a press fit even before peening. Even then it may eventually work a little loose and rotate eventually.

No matter the shape of the tenon, you want a shoulder all the way around the rod with a smaller tenon, of course.

Last edited:

- Joined

- Feb 7, 2013

- Messages

- 2,487

Welcome to the forum!

One would need to heat both pieces of brass to about 1000 degrees F. in order to silver solder them together.

Warping is possible with that procedure I would think especially on the thinner piece. Riveting the pieces together

might prove to be a better solution using some AN-470 or AN-426 aircraft rivets or even drilling and tapping the

pieces together using flat head brass screws. The aircraft rivets would contrast handsomely while flush brass screws

would be hardly noticeable. The aluminum AN-470 rivets are domed and protrude while the AN-426 end up flush.

These are available hardened or in soft condition. If you use soft rivets, the assembly could easily be done by

hammering. The domed rivets need special tools to install but the flush ones can be done with just a hammer and

a bucking bar. Like most things, there is usually more than one way to accomplish something. I'm sure you will

find the method that works best for you.

One would need to heat both pieces of brass to about 1000 degrees F. in order to silver solder them together.

Warping is possible with that procedure I would think especially on the thinner piece. Riveting the pieces together

might prove to be a better solution using some AN-470 or AN-426 aircraft rivets or even drilling and tapping the

pieces together using flat head brass screws. The aircraft rivets would contrast handsomely while flush brass screws

would be hardly noticeable. The aluminum AN-470 rivets are domed and protrude while the AN-426 end up flush.

These are available hardened or in soft condition. If you use soft rivets, the assembly could easily be done by

hammering. The domed rivets need special tools to install but the flush ones can be done with just a hammer and

a bucking bar. Like most things, there is usually more than one way to accomplish something. I'm sure you will

find the method that works best for you.

- Joined

- Apr 21, 2015

- Messages

- 582

Yes, soft solder should suffice if you go the brazing route. I wouldn’t expect much warping with silver solder, though, if you can heat both parts evenly.

If it were me, I wouldn’t do any brazing or add any additional fasteners, I’d use the end of the bar itself as an integral rivet as I said.

I’m a little confused about the project though. The fence on a marking gauge is usually adjustable (with a wedge or grub screw to lock it in place on the bar once adjusted). Are you making a fixed distance gauge, or are you making the scribe pin/knife/disc itself adjustable somehow?

If it were me, I wouldn’t do any brazing or add any additional fasteners, I’d use the end of the bar itself as an integral rivet as I said.

I’m a little confused about the project though. The fence on a marking gauge is usually adjustable (with a wedge or grub screw to lock it in place on the bar once adjusted). Are you making a fixed distance gauge, or are you making the scribe pin/knife/disc itself adjustable somehow?

Last edited:

To answer the questions, I have a small lathe (grizzly g0768). Other tools I have are hand and needle files, a bench grinder, small drill press, a few taps and dies.

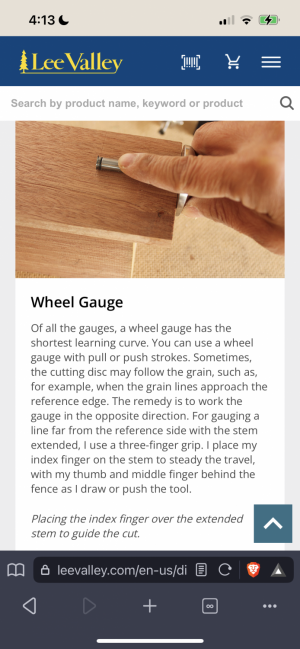

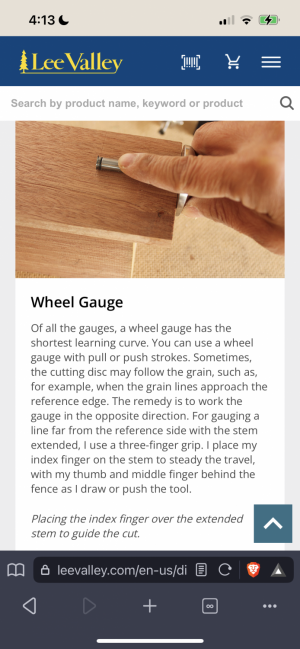

This is the fence of the gauge, and yes like the lee valley one pictured above. Once assembled, I'll put a hole through it to fit a length of drill rod, and a threaded hole for a set screw.

If I go the silver solder/brazing route, would I just sit them flush, or cut a socket for the thinner brass to seat in?

This is the fence of the gauge, and yes like the lee valley one pictured above. Once assembled, I'll put a hole through it to fit a length of drill rod, and a threaded hole for a set screw.

If I go the silver solder/brazing route, would I just sit them flush, or cut a socket for the thinner brass to seat in?

- Joined

- Feb 1, 2015

- Messages

- 9,622

This is a low impact tool. Soft soldering will be the least fussy method of joining the two pieces.