I have started on my first wobbler steam engine. I plan to install it in a RC boat running on steam. It is a double acting, 2 cylinders, and they are machined from cast iron. The bore is 3/4 and stroke is 1-1/4 inches. Pistons are brass as are the cylinder covers. The cylinders were drilled and reamed to size. My question is do I need to polish/ hone the cast cylinders? Or is the reaming enough? Thanks

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advise needed on my first Wobbler

- Thread starter todd281

- Start date

Properly reamed to size should be good.

Any machine parks can hold oil which is the seal between piston and wall.

Polish could change from round a bit and upset fit.

Priority is insuring piston is dead straight and proper fit.

Sent from my SM-G781V using Tapatalk

Any machine parks can hold oil which is the seal between piston and wall.

Polish could change from round a bit and upset fit.

Priority is insuring piston is dead straight and proper fit.

Sent from my SM-G781V using Tapatalk

Thanks for the replies. I have taken great care to ensure the cylinder is true, having bored, then faced the lower end, all without removing the cylinder from the jaws. There is less than .001 between the bore, and piston OD. The covers/heads fit well however I have some interference on the lower cover. I drilled and reamed the hole to accept the 3/16 connecting rod, but I think I may have to open that up a little. This should not be an issue, as the packing should allow for it. I am planning to use ball bearings both on the mains and the rods. I have them on hand, and have already produced the rod ends to accept them. Firstly, to get the cylinder assembly's finished and as free moving as possible. Right now, I am waiting a 4-40 tap to use for the cap screws that will hold the cylinder covers on. I will snap a few pictures and post them soon.

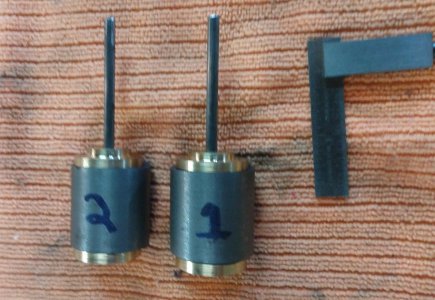

Here are some pictures as promised. Thinking ahead on this project, has brought up another question. When one mounts a wobbler cylinder, it has two ports in it that allow for the entry and exit of the steam from the cylinder. These ports, swing in an arch, and coincide with ports in the main frame. I am trying to determine the placement of the ports in the frame. It seems that steam entry, for a power stroke, should be just before TDC [or BDC] Is there a place that relates to the position of the crank, that the ports should be aligned? To say it another way. Say I have the cylinders attached to a frame, ports in the cylinders but none in the frame. Crank and journals installed. Now by rotating the crank by hand, I can determine the arch produced by the cylinder ports. However, I am unsure where, along that arch, the ports in the frame should be placed. It would seem that if it were at the extreme ends, that the piston would be midway of its travel. So hopefully someone here, understands what I am asking, and has some insight. Now off to find some graphite packing yarn. Thanks