- Joined

- Jan 20, 2016

- Messages

- 1,011

My old, tired, used air compressor has almost quit compressing air. So time for a rebuild. Thought a few pictures along the way might be interesting.

The compressor is an Emglo model DU. Rated somewhere around 18 CFM @ 125 psi. It has only been operating at about 1/4 of that since I bought it 4 years ago, so needing a rebuild isn't a surprise. In fact what is a surprise is that I haven't had to do it before now.

My findings: Out of 4 valves in the valve plates 1 is completely gone, 1 was just floating in space and the spring for one is in 3 pieces. 2 piston rings are frozen and collapsed on the pistons, one cylinder has a pretty good score, and the unloader valve is crusty.

All that and it was still working, abet taking longer and longer to fill the tank to 110 psi!

Since I don't really need the entire capacity that this thing is capable of when in tip-top shape I'm going to cut a few corners to save a few bucks. Where I should replace the bad cylinder and a couple of pistons I'm just going to hone the cylinders and re-establish ring clearance with a jewelers file (they don't make oversized pistons). I was planning on replacing the rod bearings and crank bearings but there aren't any rod bearings! No obvious play in the rod big or little ends. And the crank feels good so I'm going to take a chance and just leave the bottom end alone.

A gasket, ring, valve and air filter kit is available for about $220. I can always take it back apart later if I decide to replace something I'm not doing now.

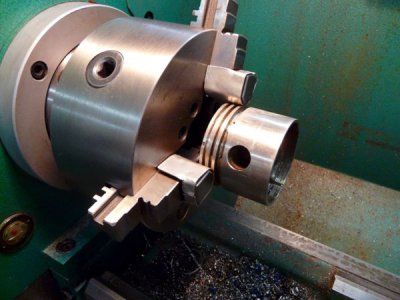

Pics;

The compressor is an Emglo model DU. Rated somewhere around 18 CFM @ 125 psi. It has only been operating at about 1/4 of that since I bought it 4 years ago, so needing a rebuild isn't a surprise. In fact what is a surprise is that I haven't had to do it before now.

My findings: Out of 4 valves in the valve plates 1 is completely gone, 1 was just floating in space and the spring for one is in 3 pieces. 2 piston rings are frozen and collapsed on the pistons, one cylinder has a pretty good score, and the unloader valve is crusty.

All that and it was still working, abet taking longer and longer to fill the tank to 110 psi!

Since I don't really need the entire capacity that this thing is capable of when in tip-top shape I'm going to cut a few corners to save a few bucks. Where I should replace the bad cylinder and a couple of pistons I'm just going to hone the cylinders and re-establish ring clearance with a jewelers file (they don't make oversized pistons). I was planning on replacing the rod bearings and crank bearings but there aren't any rod bearings! No obvious play in the rod big or little ends. And the crank feels good so I'm going to take a chance and just leave the bottom end alone.

A gasket, ring, valve and air filter kit is available for about $220. I can always take it back apart later if I decide to replace something I'm not doing now.

Pics;