- Joined

- Oct 15, 2020

- Messages

- 208

Gentlemen,

Today I finished a backing-plate adapter-plate so as to attach an 8" 3 jaw to my new 1030. Years ago, my sweetie (before she was my sweetie) saw that I was looking for a backing plate for my Midi-lathe (on the wood side) and decided to surprise me with a new chuck - she did not know that the Midi-lathe cannot handle an 8" chuck, so I ended up with it as the first bit of my machine lab - I did not have the heart to sell it, and Ebay is mean to low-volume sellers (not to mention shipping as a regular guy is stupid expensive). Anywho, I found a big-'ol cookie of scrapbinium (some kind of mild steel) and broke more carbide inserts than I'd like to admit... It took 3 days, and produced 15 gallons of blue, purple, yellow, and shiny stringy bits of steel...

Anyways, back to the story:

Many moons passed, I got me a granite and blocks, then a height-gauge, mics, approxometers, etc.... Soon enough, I had metrology enough to be sad that I had nothing to metrolize. No machines, no cutters, no materials (save for a bunch of garbage/scrap that people looked at me weird for having - till they saw the strange things I make with it).

The days and the years passed as my stash hid from the dust under plastic and in boxes, then my sweetie became my sweetie and we ran away together (with some help from the FHA ). Now I had a new shop-like environment, and the empty spaces where machines would go became even worse than simply looking at my unused granite with a sigh. The waiting was intolerable!

). Now I had a new shop-like environment, and the empty spaces where machines would go became even worse than simply looking at my unused granite with a sigh. The waiting was intolerable!

The day came when I looked at my books and it was actually possible... the day had come! IT WAS HERE!

I could do it - with help from a few years of doing credity-things - I could actually have my own machines and cutters and shiny things to cut!

With great apprehension, I gathered the goodies into digital carts and gave them the magic numbers that would make me a debt slave for a time. It's more than half paid off already.

After so many years, I had found PM (AKA QMT) by chance on Ebay - then I went to that particular horse's mouth and made the purchase. Then the corona came and ruined everything! But, PM made it happen for me

Shipping and receiving and stocking are a problem, demand and supply and angry things in east-Asia. They sent me Milly (the 727-V) without the DRO, then sent my DRO later to install, and gave me a small refund for the trouble. I actually had fun figuring out the DRO - maybe someday I can get it to control a dividing head, but that's a different thread.

Some pieces-parts on Milly were below the snuff, so PM sent me new ones that were up to snuff.

I watched on a container-boat tracking website for 6 weeks as Lizzy (the 1030 lathe) crawled across the Pacific at an average speed of 15mph - then, right as she got through the Panama, a freaking hurricane hit and tracking was lost!

Randomly, the boat (COSCO Hope... I still recall) showed up in New York and in a few weeks, I was cussing at my neighbor's engine hoist as I got her up on her stands....

Some weird thing had happened in my order and I was sent 2 turning-tool kits, so I sent one back and the threading-tool kit replacement is already in the mail to me. A change-gear hub was broken, so PM agreed to send a new one without any complaints. Also, the spring on one of the ball-oilers gave up the ghost and PM did not hesitate to declare they would send a replacement along with the others...

Through this whole adventure, I have been nervous and less than my friendly self. I don't think that I was mean or anything, but I am certain that I've been noticed as a... persnickety sort.

If anyone at PM is under the impression that I am unhappy, well, let those fears be to rest!

The machines are not perfect, but they are MINE and they are a lot of machine for the price. Making the chuck-backplate-adapter-plate (the 1030 has a weird spindle thing, so I got a backplate from PM - the chuck actually has 2 backplates due to this) was at the extreme upper end of Lizzy's ability. Whatever that steel is, I could not take more than 0.020" DOC, and the size and weight of the stock kept my RPMs well under 500 as I did not want Lizzy to dance over the shop. It took 3 days mostly to remove about 0.500" from the radius, and another 0.500" from the thickness (at 0.020" per pass... you understand). As I said, I broke more inserts than seems reasonable, and I am embarrassed to say I stalled out Lizzy more than once... she took it like a champion and I just ran that big 'ol chuck up to 1000rpm (actually about 984 was as high as the rpm-reader said it was) and it was smooth as a kitten...

SO!

On account of my delight in finally having machines all my own, and because I feel like I was a little too "needy" during the course of my purchase (though, to be fair, it is one of the largest single purchases I've ever made - aside from the house that is - and there were many details that PM handled well)...

Ode to PM (AKA QMT):

I have nothing super clever to say, but I like you guys!

Keep a 110VAC Surface Grinder in Blue, because someday you know what I'll do!

Hopefully then, I'll be easier to do business with

Thank you Precision Matthews - I don't care what people say about me not buying South Bend or Bridgeport - I am a happy guy and you meet all of my expectations for what I thought I would get.

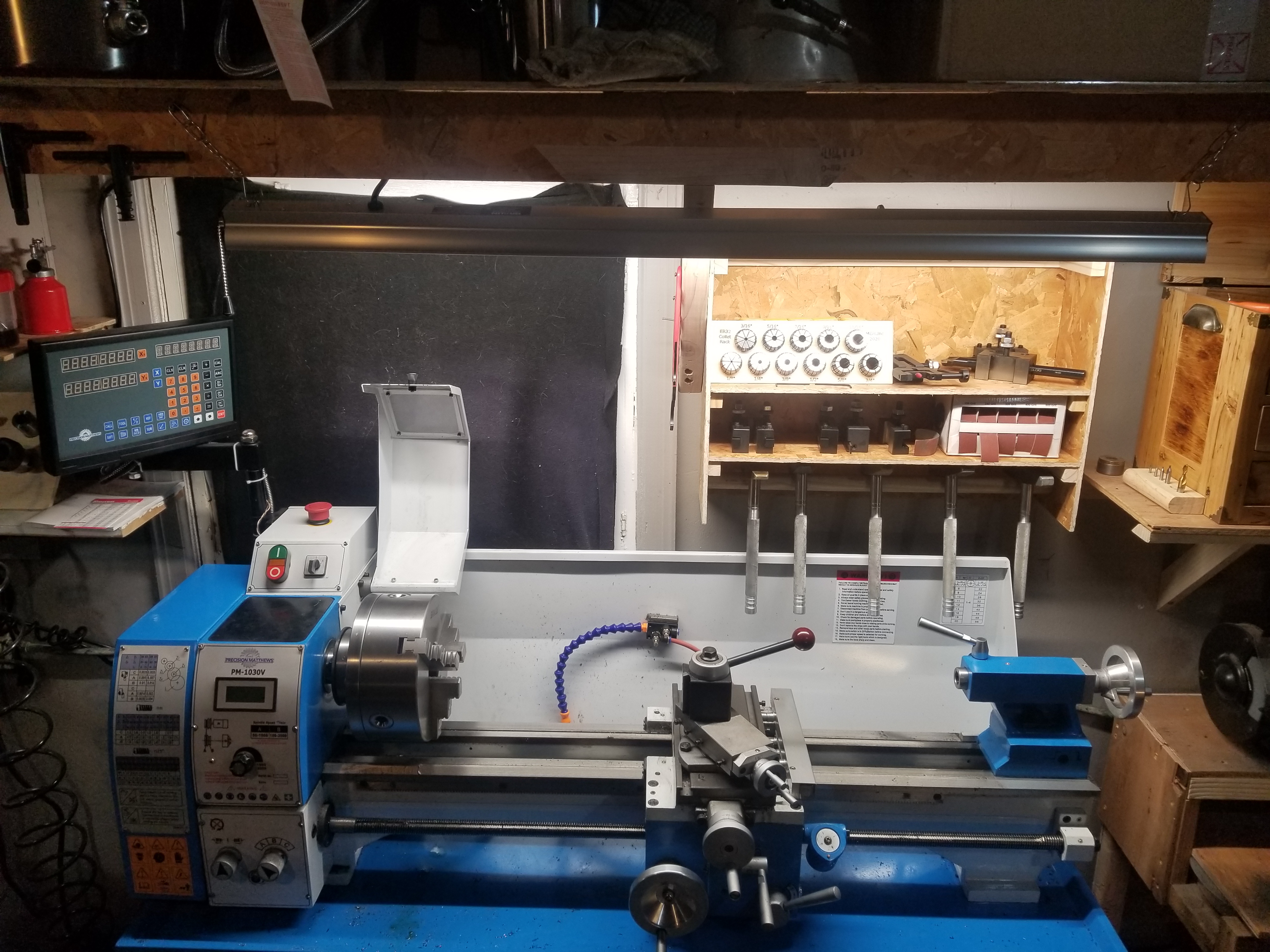

For your viewing pleasure, my 2.5-decade-in-the-making machine laboratory - Milly and Lizzy in their natural habitat... lurking and waiting to pounce on brass, aluminum, steel, copper, PTFE, Delrin......

Seriously though - keep that 110VAC surface grinder available - like seriously seriously; I can't say how irritating it would be if I had one machine that wasn't blue... I'll buy it as soon as I can get away with it! (Or, you know, you could just send it along and I'll write you a song!)

YAY!

Today I finished a backing-plate adapter-plate so as to attach an 8" 3 jaw to my new 1030. Years ago, my sweetie (before she was my sweetie) saw that I was looking for a backing plate for my Midi-lathe (on the wood side) and decided to surprise me with a new chuck - she did not know that the Midi-lathe cannot handle an 8" chuck, so I ended up with it as the first bit of my machine lab - I did not have the heart to sell it, and Ebay is mean to low-volume sellers (not to mention shipping as a regular guy is stupid expensive). Anywho, I found a big-'ol cookie of scrapbinium (some kind of mild steel) and broke more carbide inserts than I'd like to admit... It took 3 days, and produced 15 gallons of blue, purple, yellow, and shiny stringy bits of steel...

Anyways, back to the story:

Many moons passed, I got me a granite and blocks, then a height-gauge, mics, approxometers, etc.... Soon enough, I had metrology enough to be sad that I had nothing to metrolize. No machines, no cutters, no materials (save for a bunch of garbage/scrap that people looked at me weird for having - till they saw the strange things I make with it).

The days and the years passed as my stash hid from the dust under plastic and in boxes, then my sweetie became my sweetie and we ran away together (with some help from the FHA

The day came when I looked at my books and it was actually possible... the day had come! IT WAS HERE!

I could do it - with help from a few years of doing credity-things - I could actually have my own machines and cutters and shiny things to cut!

With great apprehension, I gathered the goodies into digital carts and gave them the magic numbers that would make me a debt slave for a time. It's more than half paid off already.

After so many years, I had found PM (AKA QMT) by chance on Ebay - then I went to that particular horse's mouth and made the purchase. Then the corona came and ruined everything! But, PM made it happen for me

Shipping and receiving and stocking are a problem, demand and supply and angry things in east-Asia. They sent me Milly (the 727-V) without the DRO, then sent my DRO later to install, and gave me a small refund for the trouble. I actually had fun figuring out the DRO - maybe someday I can get it to control a dividing head, but that's a different thread.

Some pieces-parts on Milly were below the snuff, so PM sent me new ones that were up to snuff.

I watched on a container-boat tracking website for 6 weeks as Lizzy (the 1030 lathe) crawled across the Pacific at an average speed of 15mph - then, right as she got through the Panama, a freaking hurricane hit and tracking was lost!

Randomly, the boat (COSCO Hope... I still recall) showed up in New York and in a few weeks, I was cussing at my neighbor's engine hoist as I got her up on her stands....

Some weird thing had happened in my order and I was sent 2 turning-tool kits, so I sent one back and the threading-tool kit replacement is already in the mail to me. A change-gear hub was broken, so PM agreed to send a new one without any complaints. Also, the spring on one of the ball-oilers gave up the ghost and PM did not hesitate to declare they would send a replacement along with the others...

Through this whole adventure, I have been nervous and less than my friendly self. I don't think that I was mean or anything, but I am certain that I've been noticed as a... persnickety sort.

If anyone at PM is under the impression that I am unhappy, well, let those fears be to rest!

The machines are not perfect, but they are MINE and they are a lot of machine for the price. Making the chuck-backplate-adapter-plate (the 1030 has a weird spindle thing, so I got a backplate from PM - the chuck actually has 2 backplates due to this) was at the extreme upper end of Lizzy's ability. Whatever that steel is, I could not take more than 0.020" DOC, and the size and weight of the stock kept my RPMs well under 500 as I did not want Lizzy to dance over the shop. It took 3 days mostly to remove about 0.500" from the radius, and another 0.500" from the thickness (at 0.020" per pass... you understand). As I said, I broke more inserts than seems reasonable, and I am embarrassed to say I stalled out Lizzy more than once... she took it like a champion and I just ran that big 'ol chuck up to 1000rpm (actually about 984 was as high as the rpm-reader said it was) and it was smooth as a kitten...

SO!

On account of my delight in finally having machines all my own, and because I feel like I was a little too "needy" during the course of my purchase (though, to be fair, it is one of the largest single purchases I've ever made - aside from the house that is - and there were many details that PM handled well)...

Ode to PM (AKA QMT):

I have nothing super clever to say, but I like you guys!

Keep a 110VAC Surface Grinder in Blue, because someday you know what I'll do!

Hopefully then, I'll be easier to do business with

Thank you Precision Matthews - I don't care what people say about me not buying South Bend or Bridgeport - I am a happy guy and you meet all of my expectations for what I thought I would get.

For your viewing pleasure, my 2.5-decade-in-the-making machine laboratory - Milly and Lizzy in their natural habitat... lurking and waiting to pounce on brass, aluminum, steel, copper, PTFE, Delrin......

Seriously though - keep that 110VAC surface grinder available - like seriously seriously; I can't say how irritating it would be if I had one machine that wasn't blue... I'll buy it as soon as I can get away with it! (Or, you know, you could just send it along and I'll write you a song!)

YAY!