- Joined

- Dec 18, 2019

- Messages

- 6,464

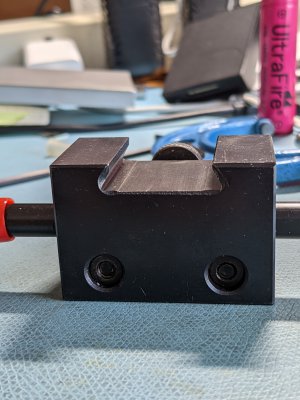

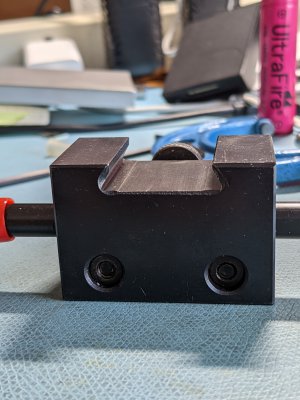

A while back I got a Circle Machine carbide boring bar, but I don't have a boring bar holder for it. I do have a cheapo OXA boring bar holder, and it is passable for steel bars. However, the stock OXA boring bar holders are NOT recommended for carbide bars due to their clamping mechanism. They use little small blocks that put extremely high local forces on the bar, which can cause carbide bar breakage. Recommended boring bar holders clamp the entire bar along the whole part and are more rigid. So I want to make a boring bar holder.

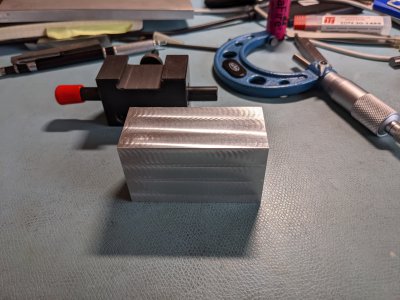

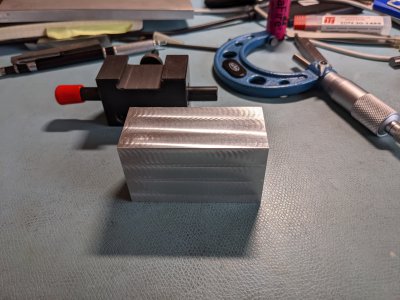

Have squared up a block of 7075 aluminum to the approximate dimensions 30 x 39 x 67 mm. This holder is for a 1/2" bar. Looking at how to measure dovetails. In my Machinery's Handbook there is a paragraph on measuring dovetails. I understand how to measure a male dovetail using two dowel pins and an outside micrometer. The part I want to make is the female piece. I don't understand how to measure the dimension y accurately. Is there some kind of tool I can use to fit to the dovetail and dowels and then measure that with an outside micrometer? What is it called? For the dowel pins, I measure 0.260" from the top of the dovetail to the machined lower dovetail surface, is a 0.250" dowel ok, or go a little smaller? The lower machined surface is about 0.160" wide before it steps down as a relief.

Have squared up a block of 7075 aluminum to the approximate dimensions 30 x 39 x 67 mm. This holder is for a 1/2" bar. Looking at how to measure dovetails. In my Machinery's Handbook there is a paragraph on measuring dovetails. I understand how to measure a male dovetail using two dowel pins and an outside micrometer. The part I want to make is the female piece. I don't understand how to measure the dimension y accurately. Is there some kind of tool I can use to fit to the dovetail and dowels and then measure that with an outside micrometer? What is it called? For the dowel pins, I measure 0.260" from the top of the dovetail to the machined lower dovetail surface, is a 0.250" dowel ok, or go a little smaller? The lower machined surface is about 0.160" wide before it steps down as a relief.