- Joined

- Mar 10, 2012

- Messages

- 125

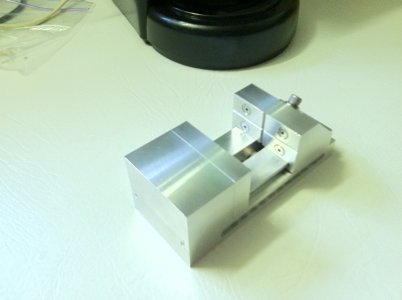

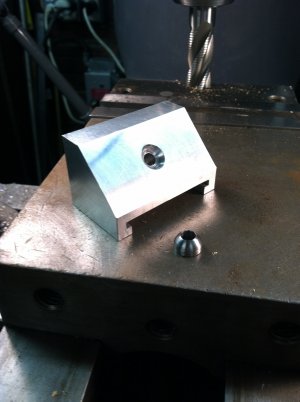

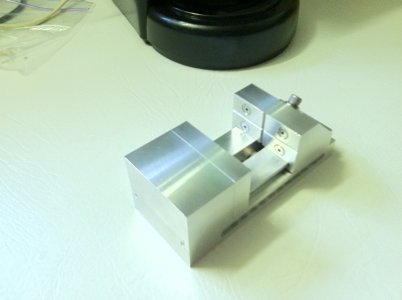

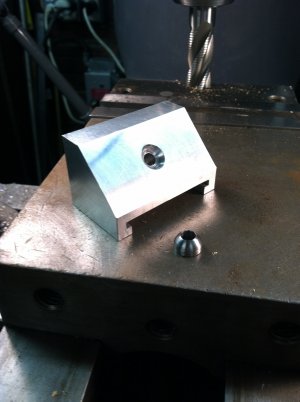

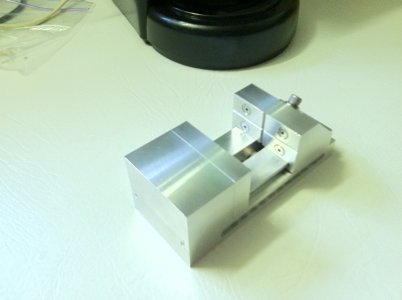

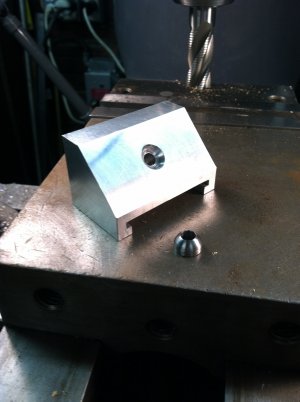

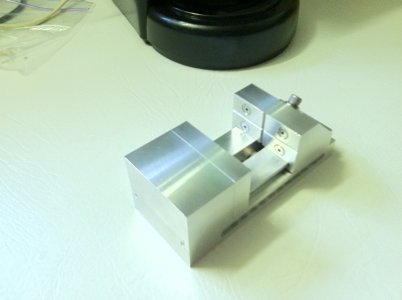

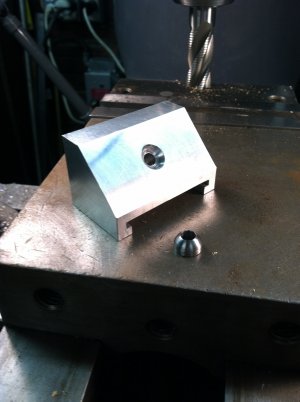

Aftera bout with pneumonia earlier this summer, I decided it was time to get back inthe saddle and finish a project I had started on a small machinist's vise. I started out a plan I saw by Dean Williams but after playing with it for a whileI tinkered with the dimensions a bit. I also decided to slot the base and jaws.I cut the half round washer for the draw screw out of stainless with my home made ball turner.

I screwed up one set of jaws getting the slotting right but finally got them to fit closely in the base. Then I tried a couple of different sizes of draw screw anchors. I ended up with the brass one pictured that I turned out of 3/4 inch stock. That allow the anchor to stay in the x axis slot in the base when loosened enough to disengage from the y axis half round slots. Milling off the bottom of the anchor allows it drop out of the half slot, and slide along in the x axis slot without dragging beneath the vise bottom.

Next,I sliced jaw faces off the "mistake" jaws I mentioned earlier, and drilled, countersunk, and slotted them. Then I drilled and tapped the jaws to accept the faces (two 1/4-20s in the fixed and, and four 8/32s in the moveable one)

I also cut 90 degree grooves in the faces to help hold roundstock. Since the faces were cut from the mistakes they don't fit flush with the base, but cosmetics aside, they work well enough. I ran a face cutter over all the surfaces to clean it up, and I'm fairly pleased with the results.

I screwed up one set of jaws getting the slotting right but finally got them to fit closely in the base. Then I tried a couple of different sizes of draw screw anchors. I ended up with the brass one pictured that I turned out of 3/4 inch stock. That allow the anchor to stay in the x axis slot in the base when loosened enough to disengage from the y axis half round slots. Milling off the bottom of the anchor allows it drop out of the half slot, and slide along in the x axis slot without dragging beneath the vise bottom.

Next,I sliced jaw faces off the "mistake" jaws I mentioned earlier, and drilled, countersunk, and slotted them. Then I drilled and tapped the jaws to accept the faces (two 1/4-20s in the fixed and, and four 8/32s in the moveable one)

I also cut 90 degree grooves in the faces to help hold roundstock. Since the faces were cut from the mistakes they don't fit flush with the base, but cosmetics aside, they work well enough. I ran a face cutter over all the surfaces to clean it up, and I'm fairly pleased with the results.