- Joined

- Jul 16, 2013

- Messages

- 43

So I was with a client a week ago and wile walking around his yard I saw a piece of Angle Iron with some stuff that was on its way to the Scrap Yard, I could not resist and politely asked if I could buy the piece from him he just smiled ( knowing my passion for shop work ) and gave it to me.

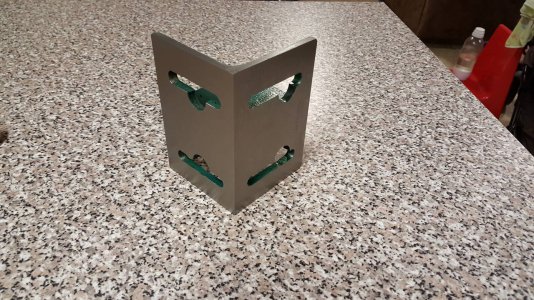

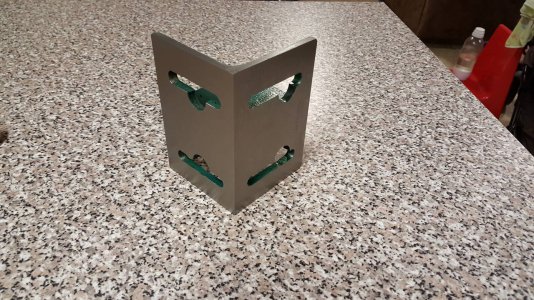

It was not pretty but quite sturdy with dimensions of 95 mm x 95 mm and 10 mm thick. So I decided to build a angle plate from it on my Alba A1 Shaper.

I really love working with the shaper as it has this soothing rocking sound and the way the metal curls while you hear the shearing noise brings me at piece after a long stressful week.

I am not going to give a tutorial on how to make a angle plate as there is a huge amount of stuff out there on how to square a angle plate. I will however note that using two cylinders is by far the best way getting close to square.

Now for the eye candy for those who would just like to see the picks

First setup I tried did not work well as I could not hold the work piece proper and there was some shifting

Then I used two Cylinders and that gave me a much better hold.

Now unfortunately I got so involved with the work that I did not take more pictures but it took a couple of passes and some measuring to get the work piece as square as what I could measure it. It seems to be about 0.05 - 0.1 mm over the 95 mm but I will admit that I only have a small 25 mm thick granite plate and I have no idea how accurate or level it is. If I use my master square I can barely see any light go through on the far edge and apparently that is quite good.

Here is the finished angle plate:

Oh yes I did weld a extra piece at the back to make it a bit more rigid.

I also love the finish that the Shaper produces and here is some closeups ..

Now to find a project that I use this plate on ........

Best Regards

Paul

South Africa

It was not pretty but quite sturdy with dimensions of 95 mm x 95 mm and 10 mm thick. So I decided to build a angle plate from it on my Alba A1 Shaper.

I really love working with the shaper as it has this soothing rocking sound and the way the metal curls while you hear the shearing noise brings me at piece after a long stressful week.

I am not going to give a tutorial on how to make a angle plate as there is a huge amount of stuff out there on how to square a angle plate. I will however note that using two cylinders is by far the best way getting close to square.

Now for the eye candy for those who would just like to see the picks

First setup I tried did not work well as I could not hold the work piece proper and there was some shifting

Then I used two Cylinders and that gave me a much better hold.

Now unfortunately I got so involved with the work that I did not take more pictures but it took a couple of passes and some measuring to get the work piece as square as what I could measure it. It seems to be about 0.05 - 0.1 mm over the 95 mm but I will admit that I only have a small 25 mm thick granite plate and I have no idea how accurate or level it is. If I use my master square I can barely see any light go through on the far edge and apparently that is quite good.

Here is the finished angle plate:

Oh yes I did weld a extra piece at the back to make it a bit more rigid.

I also love the finish that the Shaper produces and here is some closeups ..

Now to find a project that I use this plate on ........

Best Regards

Paul

South Africa