I recently picked up a set of 9/16" to 1 1/6" annular cutters as well as some other sizes I needed for ongoing projects. I wanted to use these cutters both in my lathe and mill so I set out to buy a couple holders for them. A quick search showed that most guys use a 3/4" collet in the mill and an adapter in the lathe's tail stock.

I originally bought an Accusize branded MT3 adapter for the lathe from amazon. I've bought other tooling from this brand and they were all decent quality at a good price.

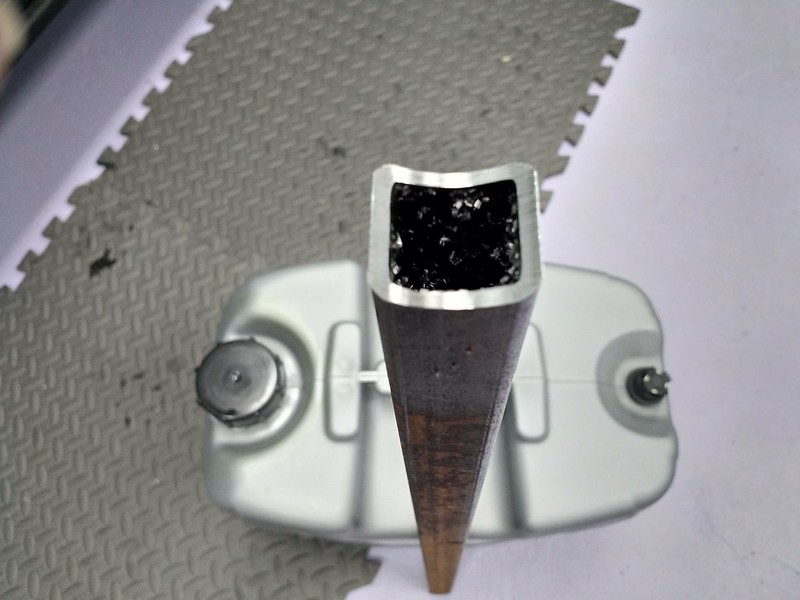

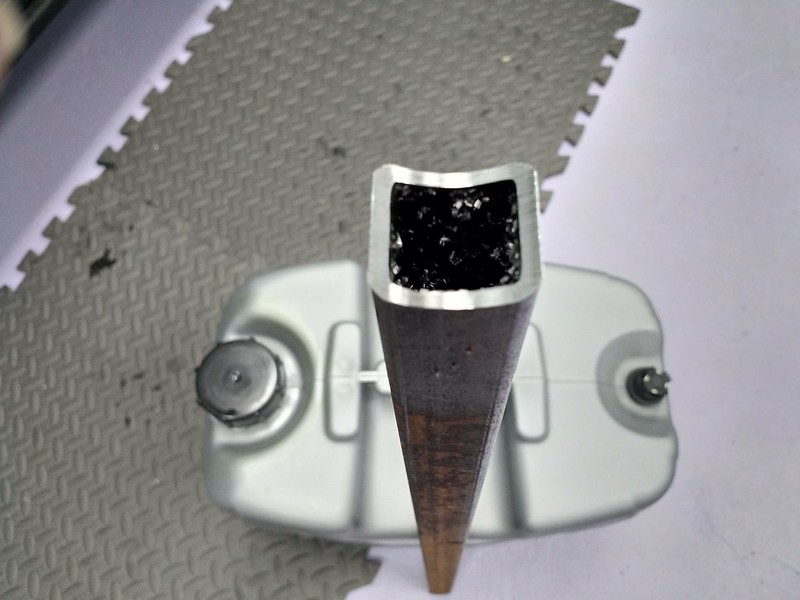

However I was rather disappointed when I received my annular cutter holder from them. First of the cutters were very loose in the holders' bore. A quick measurement with some calipers showed that the bore was .758", the shanks of the cutters were .749". Secondly the finish of the tool look like it was done with someones teeth. I think this part was cast then the critical surfaces were machined.

Shank of Accusize MT3 annular cutter holder.

So I did a bit more searching and eventually found HOUGEN 12,000 Series arbors for machine tools. I ordered their MT3 arbor which was only $22 more than the Accusize equivalent and quite a few steps up in quality. My cutters fit into this arbor as they should, a nice close slide fit. The bore on this holder was .75". It also looks like it is machined from solid stock instead of cast.

I was so happy with the Hougen MT3 Holder that I ordered their R8 arbor for the mill. However my drawbar bottomed out with this arbor so I machined a .3" spacer that fits between the drawbar hex and the top of the spindle, this took care of that problem.

Going left to right is the Accusize MT3, Hougen MT3 and Hougen R8. The groves in the Hougen arbors are to fit a coolant collar to them.

1 1/2" cutter setup in the mill for notching some 30mm square tubing. I ran this cutter at 200 RPM and hand feed with the Knee to get a feel for it.

Quite a nice cut!

Check out the fit up for welding.

Chevy

I originally bought an Accusize branded MT3 adapter for the lathe from amazon. I've bought other tooling from this brand and they were all decent quality at a good price.

However I was rather disappointed when I received my annular cutter holder from them. First of the cutters were very loose in the holders' bore. A quick measurement with some calipers showed that the bore was .758", the shanks of the cutters were .749". Secondly the finish of the tool look like it was done with someones teeth. I think this part was cast then the critical surfaces were machined.

Shank of Accusize MT3 annular cutter holder.

So I did a bit more searching and eventually found HOUGEN 12,000 Series arbors for machine tools. I ordered their MT3 arbor which was only $22 more than the Accusize equivalent and quite a few steps up in quality. My cutters fit into this arbor as they should, a nice close slide fit. The bore on this holder was .75". It also looks like it is machined from solid stock instead of cast.

I was so happy with the Hougen MT3 Holder that I ordered their R8 arbor for the mill. However my drawbar bottomed out with this arbor so I machined a .3" spacer that fits between the drawbar hex and the top of the spindle, this took care of that problem.

Going left to right is the Accusize MT3, Hougen MT3 and Hougen R8. The groves in the Hougen arbors are to fit a coolant collar to them.

1 1/2" cutter setup in the mill for notching some 30mm square tubing. I ran this cutter at 200 RPM and hand feed with the Knee to get a feel for it.

Quite a nice cut!

Check out the fit up for welding.

Chevy