- Joined

- Feb 1, 2015

- Messages

- 9,607

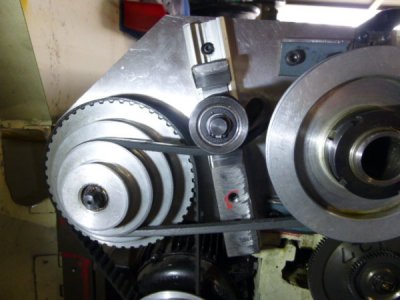

My Grizzly G0602 lathe is generally a pleasure to use. However, there is one particularly annoying shortcoming. The OEM idler is located in a diagonal slot above the belt and adjusting consists of loosening a nut on the back side of the bracket plate sliding the stud to an appropriate position and tightening the nut while maintaining tension on the belt and preventing the stud from moving in the slot.

My solution was to move the pivot point for the idler bracket to a position about 2.6" down from the top of the bracket plate and 2" from the diagonal edge of the plate. I drilled a 17/32" hole for the stud.

The second part was to make a longer idler bracket, increasing the center to center distance from 45mm to 70mm which increased the amount of adjustment available and better positioned the idler on the belt. I used a piece of 5/8" stock, milled to .620" thick by 1.20" wide by 3.95" long. The two holes were tapped for M10 x1.5mm.

Most of my machining is done with the three lowest speeds. If I need to use one of the three higher speeds, I can swing the new bracket out of the way and reinstall the OEM bracket in the slot.

My solution was to move the pivot point for the idler bracket to a position about 2.6" down from the top of the bracket plate and 2" from the diagonal edge of the plate. I drilled a 17/32" hole for the stud.

The second part was to make a longer idler bracket, increasing the center to center distance from 45mm to 70mm which increased the amount of adjustment available and better positioned the idler on the belt. I used a piece of 5/8" stock, milled to .620" thick by 1.20" wide by 3.95" long. The two holes were tapped for M10 x1.5mm.

Most of my machining is done with the three lowest speeds. If I need to use one of the three higher speeds, I can swing the new bracket out of the way and reinstall the OEM bracket in the slot.