- Joined

- Apr 14, 2014

- Messages

- 3,185

I've had a Rockwell 28-113 wood bandsaw sitting in the back of the shop since I bought it new in 1974. It's gotten very little use since I haven't been into woodworking for over 30 years. For the most part it's just taken up floor space and been used as a storage shelf. A couple weeks ago I decided it was time to either make it useful or send it off to someone who would.

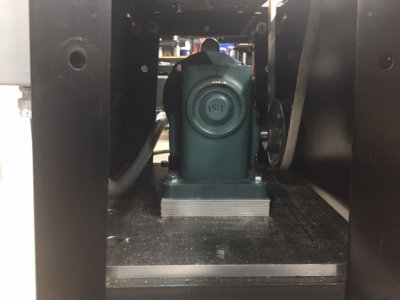

I scrounged through my stash of spare parts and came up with enough bits and pieces to convert it for cutting metal. Among the pieces and parts was a 1/2 HP TEFC motor with a 15:1 reducer, a 12" pulley, a 2.5" to 4" variable sheave, and a few other odds and ends to minimize the cost of the transition.

I finished up this morning and at least to this point have been successful. The drive slows the blade to 104 ft per minute which is the middle speed on my horizontal saw. I did a test cut on a piece of 1/4" 6061 aluminum plate and it went well. This is however an extremely light duty saw. The band wheels are plastic with rubber tires, the bearings are plain bearings, otherwise referred to as "bushings, and the only size blades it can use are 3/8" and under. I currently have a 3/8 bimetal blade on it with 10-14 tpi. It'll be interesting to see how the saw performs when used on future projects.

Here are a few pictures:

I scrounged through my stash of spare parts and came up with enough bits and pieces to convert it for cutting metal. Among the pieces and parts was a 1/2 HP TEFC motor with a 15:1 reducer, a 12" pulley, a 2.5" to 4" variable sheave, and a few other odds and ends to minimize the cost of the transition.

I finished up this morning and at least to this point have been successful. The drive slows the blade to 104 ft per minute which is the middle speed on my horizontal saw. I did a test cut on a piece of 1/4" 6061 aluminum plate and it went well. This is however an extremely light duty saw. The band wheels are plastic with rubber tires, the bearings are plain bearings, otherwise referred to as "bushings, and the only size blades it can use are 3/8" and under. I currently have a 3/8 bimetal blade on it with 10-14 tpi. It'll be interesting to see how the saw performs when used on future projects.

Here are a few pictures: