- Joined

- Aug 1, 2022

- Messages

- 137

I’ve a year into this project off and on but I’m at the point where I have something to show for my efforts.

It started with a YT video where some guy replaced a couple of pulleys on his HF bandsaw and cut some thin sheet metal. Excited by this, I then went out and found a green HF bandsaw for the price of a 1/2” Taiwanese endmill.

After getting it home and basically rebuilding the whole thing (bearings, tires, nuts/screws, blocks, etc.), I then really started doing my homework on this… yeah, should have been the first step. I then found out that it’s not as easy as the YT video makes it to be.

Undeterred, I took my time finding the bits and pieces needed. The main drivetrain pieces were: a 10:1 gear reducer, a c-face mount motor, a 14” pulley and a 2-6” stepped pulley.

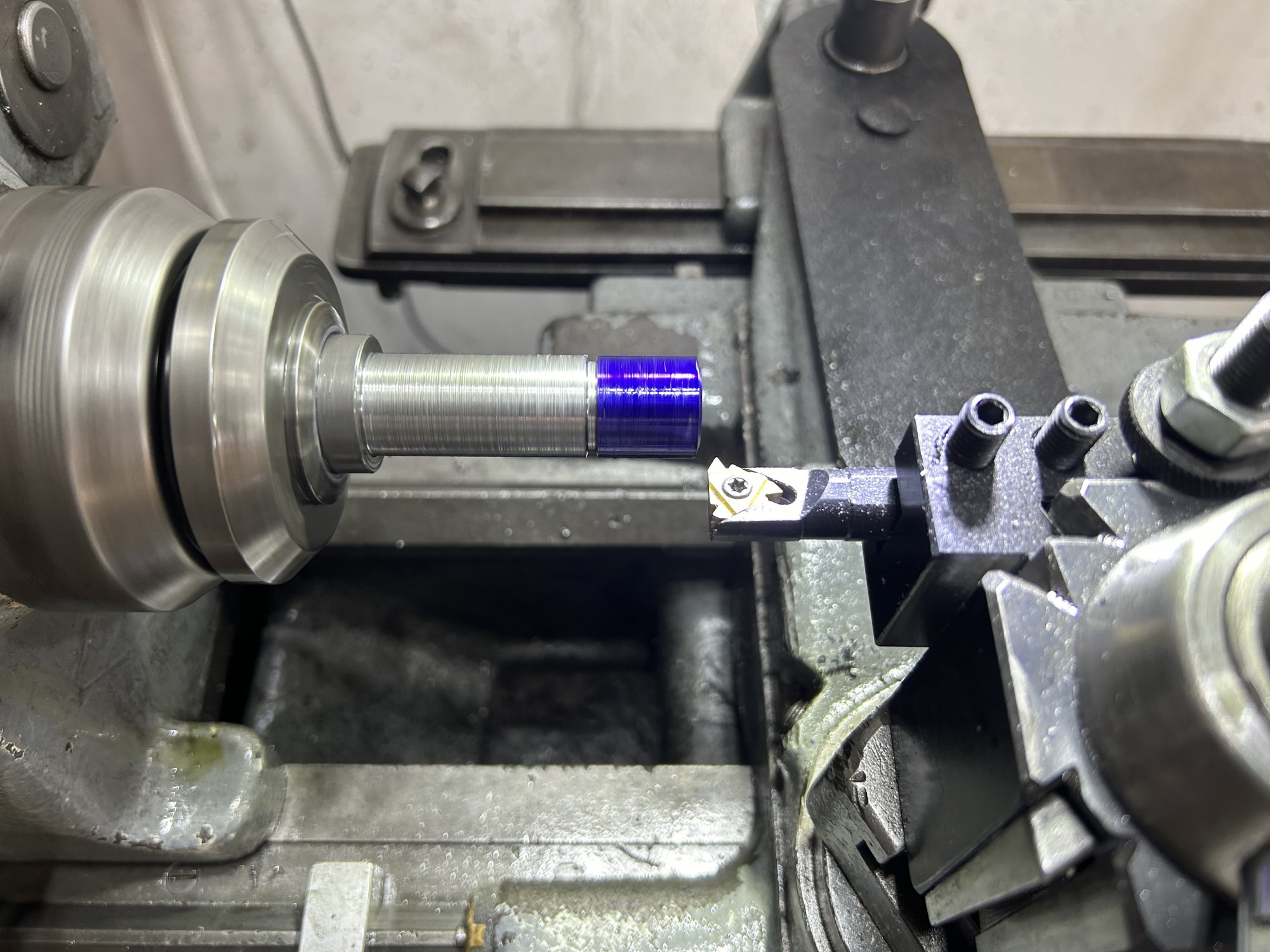

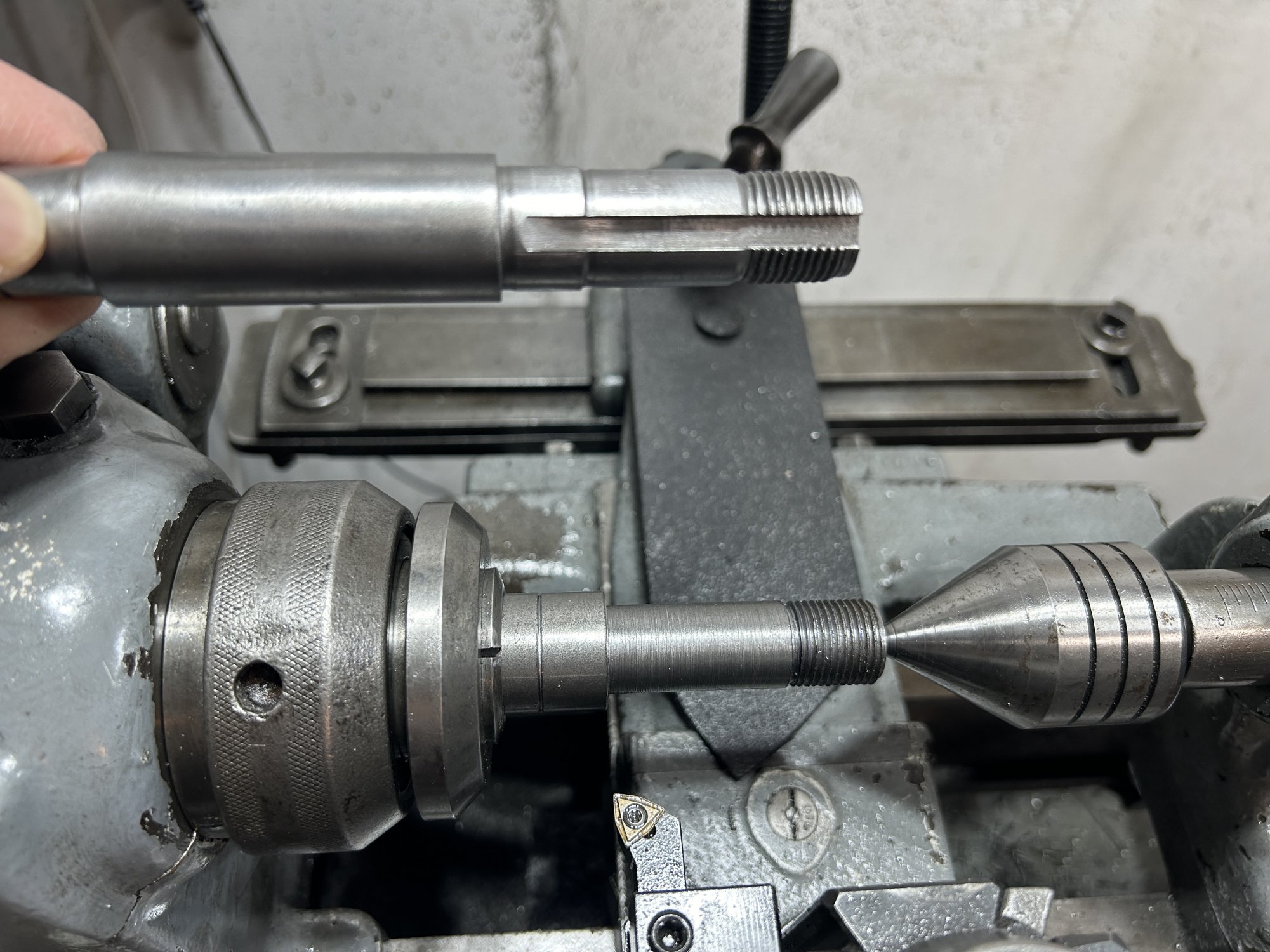

With these pieces, I made a new base to mount the motor and gear reducer. I also machined a shaft for the reducer, assorted motor/pulley shaft adapters and motor shaft keys of various adapted sizes (i.e. 3/16” on one end and 1/4” at the other end).

Just as I was putting everything together, I found another video of eliminating the deflection in the frame by welding a piece of mild steel to the cast iron frame for reinforcement. Got myself some 55 Ni electrodes and learned to weld on cast iron.

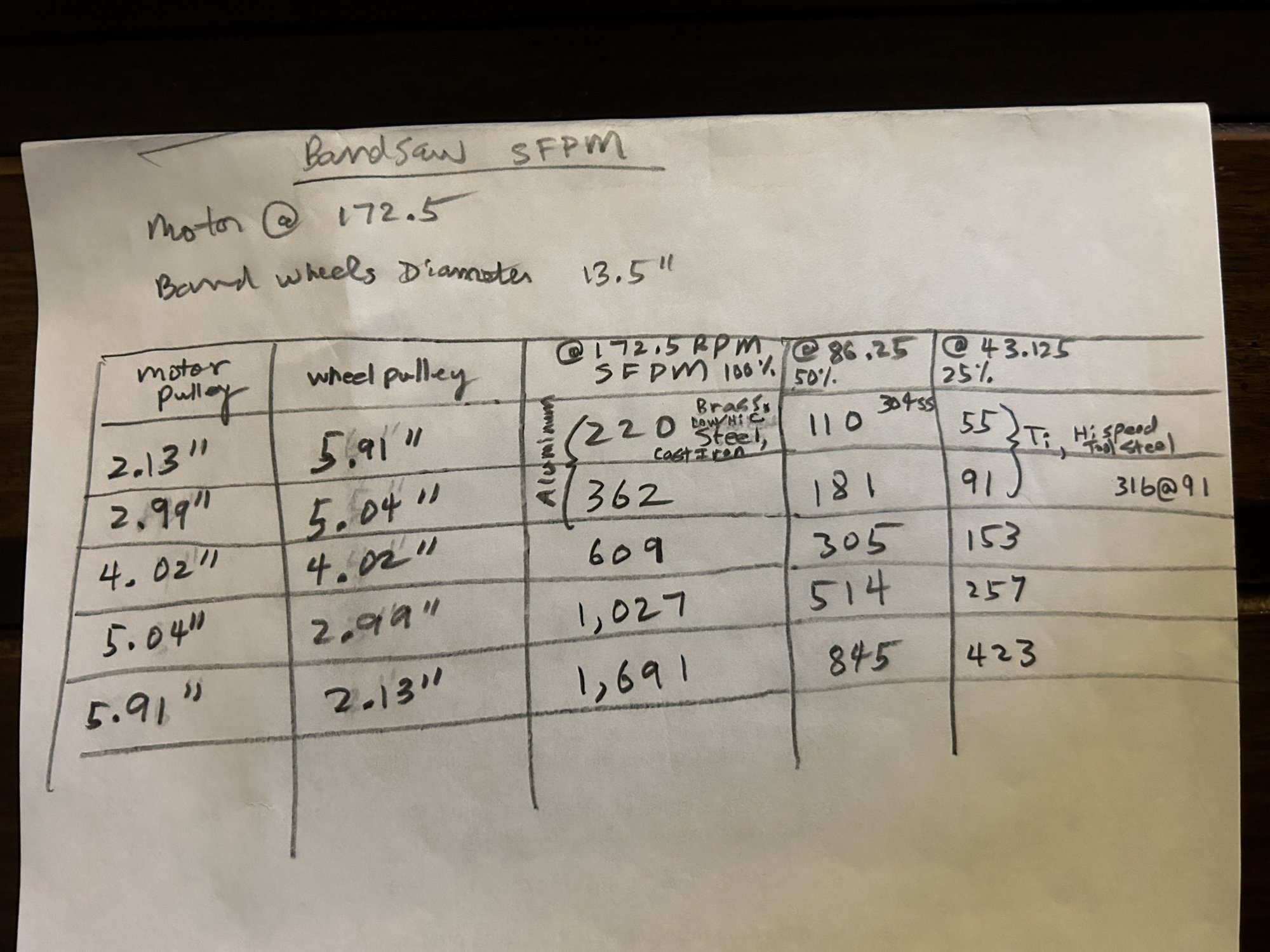

It was all coming together nicely. Wired everything up with a e-stop at knee level and a separate 110v outlet for a permanently mounted goose-neck lamp. I then put a piece of reflector on the original wood blade it came with, fired it up to take a measurement with a tach and calculated 90 SFPM with the 2” motor pulley step with the 14” saw pulley.

My latest snag came when installing a new 8/12 tpi m42 bi-metal blade. I can’t seem get the blade centered on the two wheels. That’s when I realized that the top and bottom wheels are not aligned. The bottom wheel needs to come out another 1/2” or so. So that’s where I am now. I’m turning a new shaft, so while I’m at it, I’m making it even longer on the other side to make it easier to use the other steps on the motor/reducer pulley for a total of 6 speed from 90-250 SFPM.

Once I finish the new shaft and get everything aligned, I’ll work on the finishing touches like making an enclosure for the 14” pulley and motor base out of some sheet metal I rescued from the trash.

Here are some pics of my progress. I’ll update this post as I finish.

It started with a YT video where some guy replaced a couple of pulleys on his HF bandsaw and cut some thin sheet metal. Excited by this, I then went out and found a green HF bandsaw for the price of a 1/2” Taiwanese endmill.

After getting it home and basically rebuilding the whole thing (bearings, tires, nuts/screws, blocks, etc.), I then really started doing my homework on this… yeah, should have been the first step. I then found out that it’s not as easy as the YT video makes it to be.

Undeterred, I took my time finding the bits and pieces needed. The main drivetrain pieces were: a 10:1 gear reducer, a c-face mount motor, a 14” pulley and a 2-6” stepped pulley.

With these pieces, I made a new base to mount the motor and gear reducer. I also machined a shaft for the reducer, assorted motor/pulley shaft adapters and motor shaft keys of various adapted sizes (i.e. 3/16” on one end and 1/4” at the other end).

Just as I was putting everything together, I found another video of eliminating the deflection in the frame by welding a piece of mild steel to the cast iron frame for reinforcement. Got myself some 55 Ni electrodes and learned to weld on cast iron.

It was all coming together nicely. Wired everything up with a e-stop at knee level and a separate 110v outlet for a permanently mounted goose-neck lamp. I then put a piece of reflector on the original wood blade it came with, fired it up to take a measurement with a tach and calculated 90 SFPM with the 2” motor pulley step with the 14” saw pulley.

My latest snag came when installing a new 8/12 tpi m42 bi-metal blade. I can’t seem get the blade centered on the two wheels. That’s when I realized that the top and bottom wheels are not aligned. The bottom wheel needs to come out another 1/2” or so. So that’s where I am now. I’m turning a new shaft, so while I’m at it, I’m making it even longer on the other side to make it easier to use the other steps on the motor/reducer pulley for a total of 6 speed from 90-250 SFPM.

Once I finish the new shaft and get everything aligned, I’ll work on the finishing touches like making an enclosure for the 14” pulley and motor base out of some sheet metal I rescued from the trash.

Here are some pics of my progress. I’ll update this post as I finish.