- Joined

- Jan 28, 2011

- Messages

- 3,492

I could not find the earlier posting, so I started this one. If the mods wish they can join them together.

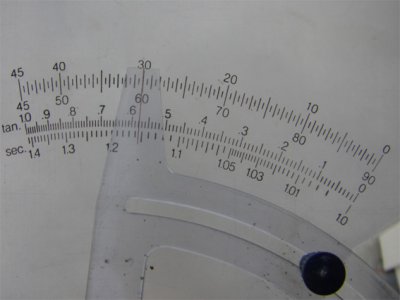

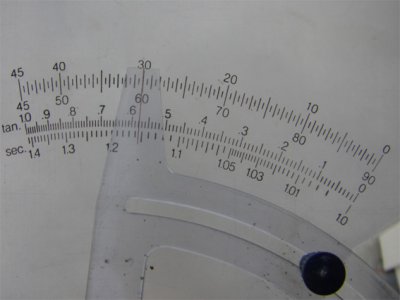

After my guerrilla milling from the weekend, mentioned in the POTD topic, I had to reset the top slide over to my usual 30 degrees. I have a problem with this lathe vs the older Atlas that I used to have, the markings are incomplete, as in they stop at 45 instead of going at least to +60. I have to still make a better mark but in the mean time I use the same Adjustable Computing Trig-scale Triangle that I have used on the table saw and on the drawing board. I include a couple pictures showing the Triangle in use and a close up of the scale.

I simply set the triangle against the chuck or face plate and then bring the top slide into near contact and adjust the slide to line up with the edge. In my case, the top slide is square to the direction of travel so there is no gap present as I move the slide back and forth, but I have seen some machines, where the slide has to have a bit of a gap either one end or the other to maintain proper relationship to the edge as it is moved along. Now that I have the top slide set at the right angle I will make a new mark that lines up with the 30 for quicker setup.

See link for example of the triangle.

http://www.draftingsteals.com/catal...djustable-computing-trig-scale-triangles.html

I hope this will be of help to other owners of these poorly marked lathes and other machinery setups as well.

Pierre

After my guerrilla milling from the weekend, mentioned in the POTD topic, I had to reset the top slide over to my usual 30 degrees. I have a problem with this lathe vs the older Atlas that I used to have, the markings are incomplete, as in they stop at 45 instead of going at least to +60. I have to still make a better mark but in the mean time I use the same Adjustable Computing Trig-scale Triangle that I have used on the table saw and on the drawing board. I include a couple pictures showing the Triangle in use and a close up of the scale.

I simply set the triangle against the chuck or face plate and then bring the top slide into near contact and adjust the slide to line up with the edge. In my case, the top slide is square to the direction of travel so there is no gap present as I move the slide back and forth, but I have seen some machines, where the slide has to have a bit of a gap either one end or the other to maintain proper relationship to the edge as it is moved along. Now that I have the top slide set at the right angle I will make a new mark that lines up with the 30 for quicker setup.

See link for example of the triangle.

http://www.draftingsteals.com/catal...djustable-computing-trig-scale-triangles.html

I hope this will be of help to other owners of these poorly marked lathes and other machinery setups as well.

Pierre