- Joined

- Jan 2, 2020

- Messages

- 10

Yeah!!

Just finished the wiring, must have done it right. My Cincinnati mill is alive after sitting in my shop for a year. As my "handle" says, I'm greener than a July cornfield and this is my first non introduction post concerning at least being able to make chips and my first mill.

The only paperwork that I have is my receipt and I'm wondering first of all how to ID my machine and order or download some information on it. Hope you guys let me "lean" on you for a while, that is with your collective knowledge and maybe incan get me on my feet.

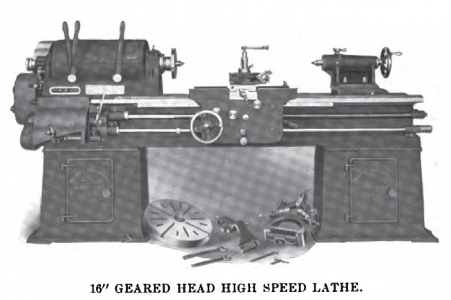

I also have an old (<1912) Prentice Bros. Lathe that now has power and is "alive".

Been waiting for this day for a long time, now I don't know what to do .

.

Edit-better level it up, there's a very slight "rock" to it sitting on the concrete. What's the best footing for it? Leave it on the 'crate and shim it, or something like conveyor belting?

Just finished the wiring, must have done it right. My Cincinnati mill is alive after sitting in my shop for a year. As my "handle" says, I'm greener than a July cornfield and this is my first non introduction post concerning at least being able to make chips and my first mill.

The only paperwork that I have is my receipt and I'm wondering first of all how to ID my machine and order or download some information on it. Hope you guys let me "lean" on you for a while, that is with your collective knowledge and maybe incan get me on my feet.

I also have an old (<1912) Prentice Bros. Lathe that now has power and is "alive".

Been waiting for this day for a long time, now I don't know what to do

Edit-better level it up, there's a very slight "rock" to it sitting on the concrete. What's the best footing for it? Leave it on the 'crate and shim it, or something like conveyor belting?