-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any recommendations on electrical control troubleshooter in Northeast Texas?

- Thread starter taltexan

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,313

What type of problems? Maybe we can help from here

Thanks for the reply

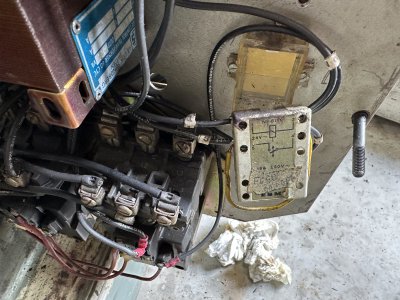

Problem 1…..rapids will not work with button. Button is the green one in photo. One Contactor for rapids and one for feed. Both contactors work manually. Feed and rapids motor runs in same direction counterclockwise. Push button is good.

Problem 2……Feed button does not work without spindle running and doesn’t latch when pushed in. With spindle running and feed button pushed in it’s in the rapid mode instead of feed mode.

Spindle buttons work as they should. They change spindle directions and latch until stop button is pushed.

Problem 1…..rapids will not work with button. Button is the green one in photo. One Contactor for rapids and one for feed. Both contactors work manually. Feed and rapids motor runs in same direction counterclockwise. Push button is good.

Problem 2……Feed button does not work without spindle running and doesn’t latch when pushed in. With spindle running and feed button pushed in it’s in the rapid mode instead of feed mode.

Spindle buttons work as they should. They change spindle directions and latch until stop button is pushed.

When you press the button, the contactor doesn’t pull in? If so, there are really only a few possibilities:

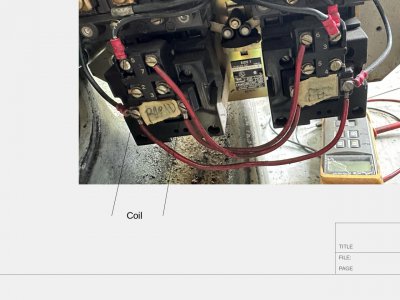

1) No voltage is getting to the contactor coil - Measure it and see.

2) If voltage is present, coil may be open. Measure it and see (powered off).

3) If coil measures OK, and voltage measures OK, contactor armature may be sticky.

1) No voltage is getting to the contactor coil - Measure it and see.

2) If voltage is present, coil may be open. Measure it and see (powered off).

3) If coil measures OK, and voltage measures OK, contactor armature may be sticky.

- Joined

- Apr 30, 2015

- Messages

- 11,313

I've been studying the material you posted- both problems would make sense if one of the contactors was not energizing

Having some alligator clips or clip leads for your meter would be very helpful at this point, since you could clip on, then watch the meter

while you press buttons. First tests should be with power off, just testing for continuity:

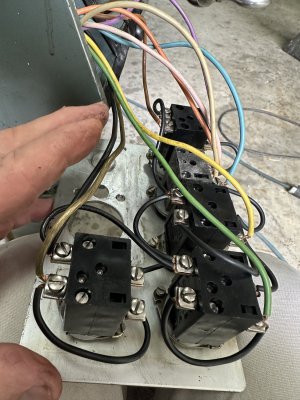

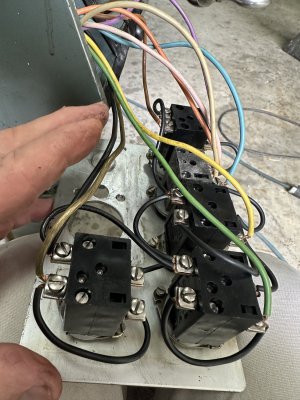

All of the contactor coils should be checked for continuity- for each coil remove wires from one of the two terminals before checking to avoid false readings. Each coil should read somewhere in the neighborhood of 100 ohms (if they draw .25 amp @ 24 volt) or so- they could measure

as low as 50 ohms if they draw half an amp each

I'll post a pic showing the coil terminals--- 5 and 7 are the normally closed contacts for the left unit, 6 and 3 for the right I believe

Having some alligator clips or clip leads for your meter would be very helpful at this point, since you could clip on, then watch the meter

while you press buttons. First tests should be with power off, just testing for continuity:

All of the contactor coils should be checked for continuity- for each coil remove wires from one of the two terminals before checking to avoid false readings. Each coil should read somewhere in the neighborhood of 100 ohms (if they draw .25 amp @ 24 volt) or so- they could measure

as low as 50 ohms if they draw half an amp each

I'll post a pic showing the coil terminals--- 5 and 7 are the normally closed contacts for the left unit, 6 and 3 for the right I believe

Last edited:

- Joined

- Apr 30, 2015

- Messages

- 11,313

Which model Abene is this? VHF-3? Are these problems new or pre-existing? Has the wiring been messed with by a previous owner?

As you probably know, those contactors are not only vintage, they're antiques

And the 24 volt coil versions are rarer than the 110 volt version

It might be possible to swap parts- either coils or contacts- I'm not real familiar with this old stuff but I did see some

used units for sale on Ebay with 110 volt coils.

Probably, the best long term solution would be to either upgrade to newer contactors or convert the machine to VFD

Either one would require a knowledgeable electrical buddy to do some reverse-engineering and re-wiring

As you probably know, those contactors are not only vintage, they're antiques

And the 24 volt coil versions are rarer than the 110 volt version

It might be possible to swap parts- either coils or contacts- I'm not real familiar with this old stuff but I did see some

used units for sale on Ebay with 110 volt coils.

Probably, the best long term solution would be to either upgrade to newer contactors or convert the machine to VFD

Either one would require a knowledgeable electrical buddy to do some reverse-engineering and re-wiring

Last edited:

It’s a VFH3. I just bought it and it was delivered with the issues. The AB contactors are 24v control, wired 240 3 phase. I have 480 so I’m running thru a step down transformer. I would upgrade but I’m still hunting for a knowledgeable person to start.

- Joined

- Apr 30, 2015

- Messages

- 11,313

I think you'd be better served by trying to find a local whiz kid who is willing to spend some time on it- it's a bit more than I want

to try to tackle from this end- we could be getting into hundreds of posts

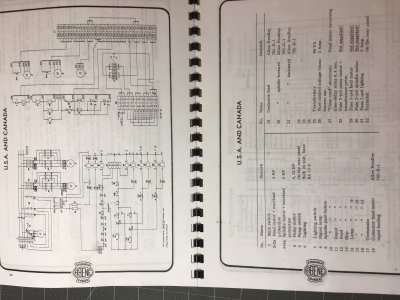

That little relay is supposed to be a 0.4 second time delay according to the parts list. I don't know if it's a close after delay or open after delay

Just one of many things I don't know about how the machine is supposed to work-

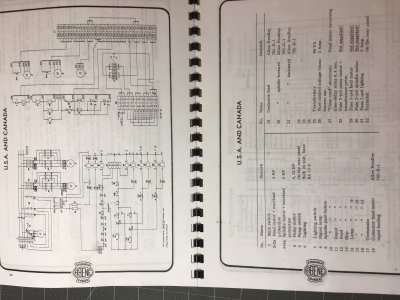

Also, it looks to me like there are a pair of contactors for each motor. The pair on one side is forward and reverse for rapids, and the pair

on the other side is for the feed, forward and reverse. I think. Each pair's coil is cross-connected to enable only one to energize at a time. (fail-safe) For example, you can see on the schematic 20 and 21 are cross-connected with the opposing NC contacts. All industrial systems have this

feature to prevent putting a direct short on the power line.

Anyhow, if I was troubleshooting it myself I would first:

1) Check all coils and normally closed contacts for continuity

2) Check and retighten all the screws on the big terminal strip

3) Put the proper time delay relay in place (or determine if the Omron you have can be used temporarily, and how that circuit works)

4) While doing all that I would learn all the button functions (I've never touched an Abene before)

5) Check all the pushbuttons for continuity

Then, if I still had not found the problem, I would have to start doing point to point tracing with and without power. Bit of a job, impossible

to tell how long it would take. Ten minutes or ten hours

to try to tackle from this end- we could be getting into hundreds of posts

That little relay is supposed to be a 0.4 second time delay according to the parts list. I don't know if it's a close after delay or open after delay

Just one of many things I don't know about how the machine is supposed to work-

Also, it looks to me like there are a pair of contactors for each motor. The pair on one side is forward and reverse for rapids, and the pair

on the other side is for the feed, forward and reverse. I think. Each pair's coil is cross-connected to enable only one to energize at a time. (fail-safe) For example, you can see on the schematic 20 and 21 are cross-connected with the opposing NC contacts. All industrial systems have this

feature to prevent putting a direct short on the power line.

Anyhow, if I was troubleshooting it myself I would first:

1) Check all coils and normally closed contacts for continuity

2) Check and retighten all the screws on the big terminal strip

3) Put the proper time delay relay in place (or determine if the Omron you have can be used temporarily, and how that circuit works)

4) While doing all that I would learn all the button functions (I've never touched an Abene before)

5) Check all the pushbuttons for continuity

Then, if I still had not found the problem, I would have to start doing point to point tracing with and without power. Bit of a job, impossible

to tell how long it would take. Ten minutes or ten hours

Last edited:

- Joined

- Dec 18, 2022

- Messages

- 1,675

An Hour North of Tyler? Sulphur Springs?I’ve got two milling machines that have electrical issues. I have the schematics on both machines. Machines are manual, one has a pendant. I’m located about an hour North of Tyler. Thanks

Ahhhh Just noticed Quitman, Home of Sissy Spacek....