Thanks for the discussion, I've enjoyed this! (While I was out in the shop cutting out a part - incorrectly, it turns out, but I need to take off more metal, not put some back, so it's just some enforced rework time).

I have no experience with SolidWorks, but have used AutoCAD. My first attempt at a 3D CAD program was TurboCAD, which made me give up. Just never got it into my head. Thing is, my initial use was for jewelry, but as versions went by (I started with Rhino 3), I drifted more and more to little parts for models. I've used Rhino to model my house for laying out the addition we put on, and for modeling rings.

I can sit down with Rhino and produce a model like my house from the primitive shapes (cylinders, boxes, and so on) and generally get it to do what I want. I'm sure, though, that I don't use a tenth of its capability - I've never lofted curves, except during a tutorial, and only rarely have used the fillet command. Some of Rhino's insistence that solids and surfaces are from separate universes still baffles me. All I'd really be buying 6 for would be the bug fixes and improvements to the basics.

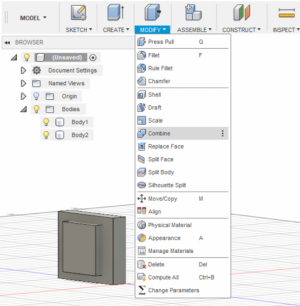

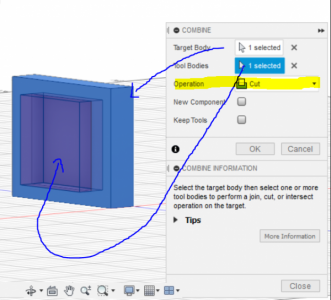

The main issue I have now is the cost. I took an early retirement offer a couple of years ago, and while there's a whole lot about retirement I love and would recommend to anyone, the reduced income isn't one of them. To replace Rhino and Deskproto, both of which could use it, I'm looking at close to $800. That could probably do my next dream job of upgrading my spindle. Fusion is the only real alternative to upgrading my software. I've worked through a handful of exercises, but just haven't had that "Ah ha!" moment.

Maybe by now there's a Fusion 360 for Rhino users tutorial out there.