- Joined

- Sep 10, 2013

- Messages

- 595

Hi

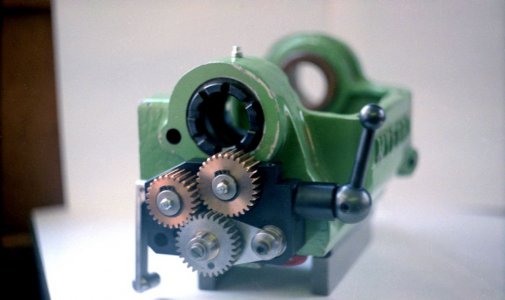

I have been studying the Meeks dog clutch. I saw a video of Jim Schroeder's G0602 lathe cutting single point threads and he made it look like a piece of cake. G Meeks designed a single dog transmission to add to a lathe and which has movable bidirectional trips that shift the lathe and lead screw in to neutral. so it can be reversed for next threading pass. I would like to make one for my Clausing 100 mkIII. What really makes this all work so well is a quick retractable tool that move the cutter back .150 or so, so you can reverse the lead screw back to the start. You can see it here http://www.hobby-machinist.com/showthread.php?t=20806 If anyone has done one or would like too, let me know. If you have better idea for the clausing I would like to here it. I know it has a tumbler but I'm worried about breaking a gear reversing it while it is running.

Thanks

CH

I have been studying the Meeks dog clutch. I saw a video of Jim Schroeder's G0602 lathe cutting single point threads and he made it look like a piece of cake. G Meeks designed a single dog transmission to add to a lathe and which has movable bidirectional trips that shift the lathe and lead screw in to neutral. so it can be reversed for next threading pass. I would like to make one for my Clausing 100 mkIII. What really makes this all work so well is a quick retractable tool that move the cutter back .150 or so, so you can reverse the lead screw back to the start. You can see it here http://www.hobby-machinist.com/showthread.php?t=20806 If anyone has done one or would like too, let me know. If you have better idea for the clausing I would like to here it. I know it has a tumbler but I'm worried about breaking a gear reversing it while it is running.

Thanks

CH