- Joined

- May 15, 2019

- Messages

- 6

Dear machinists,

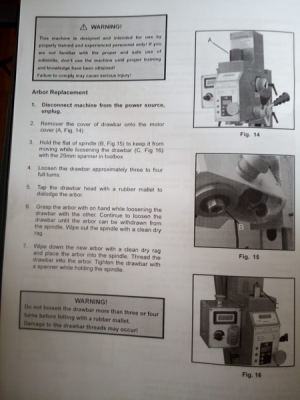

I am new in this forum. Actually, I am mill and lathe hobbyist. Recently I bought my first millIing machine, a WARCO 14 VS MILL. Because I am a beginner in milling and turning, I have started to buy a lot of end mills, different kind of, new and used end mills. I tried to extract 2MT B16 tapped 10mm arbor provided by the manufacturer in order to insert a new MT2 end mill. Surprise! It is stuck! I tried handbook procedure, but unsuccessfully.

This is the reason to write for help on this side.

I need help! Dear machinists, please send me your method to extract stuck arbor.

Thank you for reading my post.

I am new in this forum. Actually, I am mill and lathe hobbyist. Recently I bought my first millIing machine, a WARCO 14 VS MILL. Because I am a beginner in milling and turning, I have started to buy a lot of end mills, different kind of, new and used end mills. I tried to extract 2MT B16 tapped 10mm arbor provided by the manufacturer in order to insert a new MT2 end mill. Surprise! It is stuck! I tried handbook procedure, but unsuccessfully.

This is the reason to write for help on this side.

I need help! Dear machinists, please send me your method to extract stuck arbor.

Thank you for reading my post.