I've spent the last 24 hours debating whether to tear the whole thing apart and basically rebuild it OR to build my own design using the two good steppers, spindle and table along with an Arduino/Raspberry Pi based H bridge controlled power supply. Your brilliant post is perfectly timed for me. I'd sure read any of your updates religiously. Thanks for your hard work.

Thanks, Arlo. From your post, though, I am not sure what you are planning - do you want a full 3 axis CNC machine? If so, then the stepper driver I used in my first post might not be good enough for that. I chose it because it was cheap, and for my application there is no need for speed or much torque to speak of. If I were going to CNC a mill, where speed and torque do matter, I would use a better stepper driver, like a Gecko g540 or bigger, depending on the kind of mill you have. Also, you would probably need a full PC to run Windows/Mach3 to drive the thing as G-code interpretation and bit diddling a parallel interface is very compute intensive, beyond the capability of my Arduino, so far. (I am showing my experience, er, bias, here in that the computer could also be running Linux and LinuxCNC - but AFAIK a Raspberry Pi also doesn't have the horsepower for that, either, but I could be wrong about that since I don't follow that world much.)

Anyway, there are lots of guys that converted their mills to CNC - there are forum groups on CNCZone.com or Yahoo groups or Google groups that discuss just that.

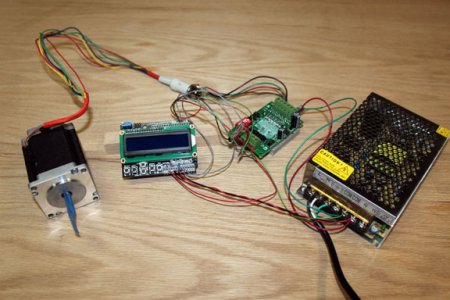

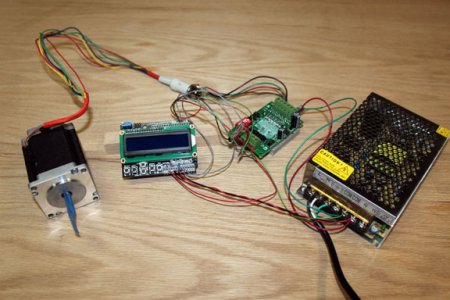

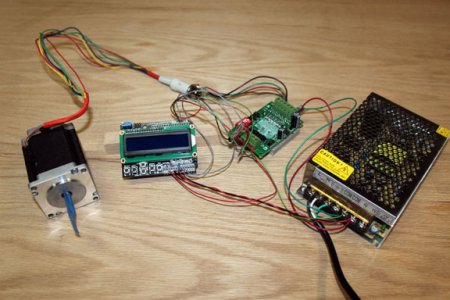

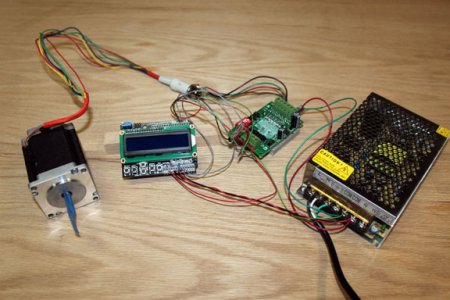

I don't want to discourage innovation here - if you really do want to try to use the setup to do something in between manual and a full CNC - kind of like a smarter power feed/DRO on each axis, then this might be a good place to start, but I would look at enhanced speed control, and some feedback for end stops and/or home positions. (I built my own power feed on my mill, shown

here, but I used a cheap gear motor, not a stepper. I guess you could swap that with this setup.)

If you did this, your out-of-pocket would be about the same as for a full Linux CNC, though, but now you need to deal with the world of CAD.