- Joined

- Mar 12, 2021

- Messages

- 63

Hello,

Was doing some prep work for the big move of pm-932v to the basement (de-palleting) and also had to pull the table.

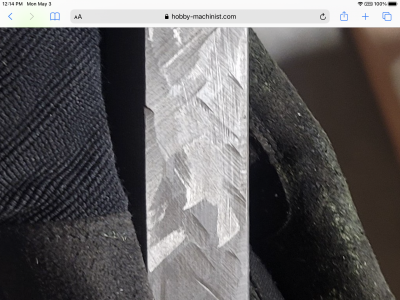

Being a new to this kind of machinery I had a question about the gib, pictured is my x axis gib. And that is the face that mates to the male side of the dovetail on the table. The side facing the other way so to the front side of the saddle is just smooth with two marks from the x axis locks. And the narrow top and bottom faces are lightly ribbed

Now I know scraping is a thing and I understand that concept this just seemed quite rough/aggresive which just had me curious If this is right/expected or if gibs are normally scrapped. I feel like it must be scraped or some attempt at something akin to scraping given the haphazard orientations but just didn't quite look as much like what I had seen when reading about scraping.

I can try and get a better image showing more detail as it seems pretty pronounced.

I haven't checked it for flatness yet waiting for my stone to hopefully show up, but I guess my bandsaw table should give me a rough idea.

Was doing some prep work for the big move of pm-932v to the basement (de-palleting) and also had to pull the table.

Being a new to this kind of machinery I had a question about the gib, pictured is my x axis gib. And that is the face that mates to the male side of the dovetail on the table. The side facing the other way so to the front side of the saddle is just smooth with two marks from the x axis locks. And the narrow top and bottom faces are lightly ribbed

Now I know scraping is a thing and I understand that concept this just seemed quite rough/aggresive which just had me curious If this is right/expected or if gibs are normally scrapped. I feel like it must be scraped or some attempt at something akin to scraping given the haphazard orientations but just didn't quite look as much like what I had seen when reading about scraping.

I can try and get a better image showing more detail as it seems pretty pronounced.

I haven't checked it for flatness yet waiting for my stone to hopefully show up, but I guess my bandsaw table should give me a rough idea.