- Joined

- Dec 23, 2020

- Messages

- 59

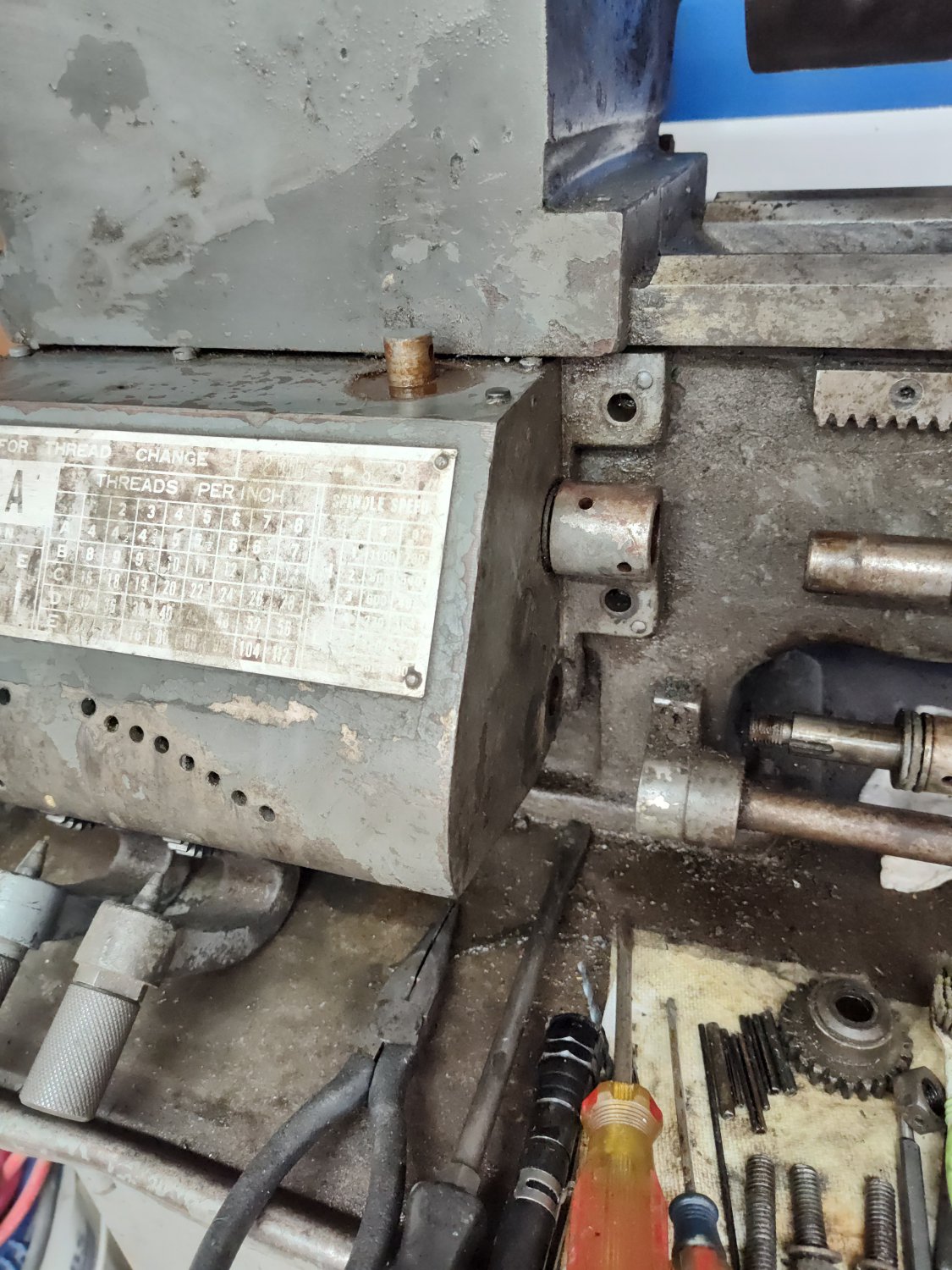

I've started disassembly of my Samson (Tida) 5aa to clean it up. There are two pins on the gearbox casting that are keeping it from coming off. I've tried prying them out with the casting but am being moderately gentle for fear of breaking the casting (the top lid casting and the motor cover casting are already broken from the prior owner!)

Anyone know if I should be able to pry these off or whether I need to grind the heads off (and then use them as alignment pins when reassembling)? Or is there another way to get them out?

Extra picture for perspective

Anyone know if I should be able to pry these off or whether I need to grind the heads off (and then use them as alignment pins when reassembling)? Or is there another way to get them out?

Extra picture for perspective