-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are these chucks as lousy as their low price leads me to believe?

- Thread starter Senna

- Start date

- Joined

- Aug 18, 2013

- Messages

- 31

Why spend the 200 bux on ChiCom garbage?

For the same money I just found a lightly used Burnerd at Lost Creek Machine and Blueball Machinery had similar for a good price.

As long as they haven't been abused or crashed I would rather deal with the nuances a used chuck would have.

For the same money I just found a lightly used Burnerd at Lost Creek Machine and Blueball Machinery had similar for a good price.

As long as they haven't been abused or crashed I would rather deal with the nuances a used chuck would have.

- Joined

- Nov 27, 2012

- Messages

- 7,858

Well I got the chuck today, typical China quality...well I've had China chucks they were better out the box. The one I received does not open & close very well out the box. It's very tight & "gritty". Well of course it is, the damn scroll & jaws are covered in grit & tiny shavings! Like any Asian import chuck I've had I always completely disassemble them, clean, & deburr before using.

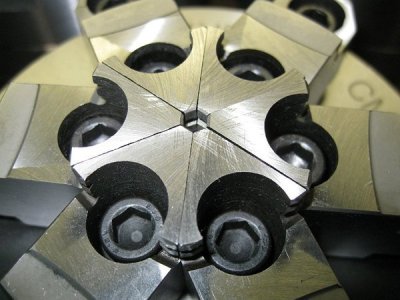

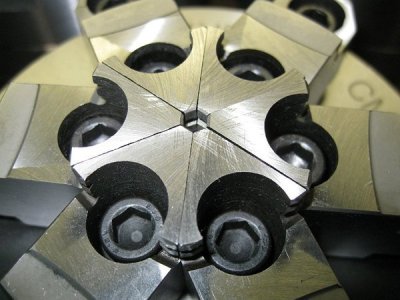

As I suspected it is 6.25", well 160mm/6.3" to be exact just like my Bison. The through hole is 1.75" which I didn't think it would be. The jaws are able to grip down to 3/16", my Bison 6-jaw only gets down to 3/8".

Here's something that I don't see often, the pinion faces have a bare machined finished (no functional importance of course).

The one I got the jaws don't mesh near as well as my Bison, you can see the two jaws in the lower right corner is even worse. Not sure if it was a grinding issue or if it's because of all that crap inside of it. Hopefully it does clean up & goes away.

Since I bought this to use on a rotary table I have no way of measuring run out since I don't have a backplate for it & I won't be making one for the lathe. My 3 jaw that came with the lathe is 6" so the backplate is too small.

I decided to try something, not something I would trust as there's too much error involved but it gave me a rough measurement with what I had on hand.

I chucked up a piece of Thomson shafting that I use for checking runout in the 4-jaw & indicated. Was going to try clamping the 6-jaw on the end.

Not sure why but I was getting weird readings so I decided to try the same with my Bison which worked better.

I estimate about just under .002" runout, measuring the register on the back & the body was about the same. The register is not machined very smooth. Crappy phillips screws holding the back cover & set screws for the pinion but no surprise there. Typical cheap tiny chuck key which I always just toss in a box anyway. They did include a microfiber cloth with machining related pics on it for cleaning, never seen that before.

So my thoughts on a quick evaluation, typical you get what you pay for with Asian import stuff. Will I keep it? Yes. Would I buy it again knowing what I know now? Probably not, but with some work it might turn out to be a decent chuck, good enough for me to use on the rotary table anyway. We'll see after I spend some time on it to go through & clean up everything, I'm a bit scared to see what it looks like inside.

The Fuerda/Gator semi steel 6-jaw would be a much better buy for a couple hundred more & it's adjustable.

As I suspected it is 6.25", well 160mm/6.3" to be exact just like my Bison. The through hole is 1.75" which I didn't think it would be. The jaws are able to grip down to 3/16", my Bison 6-jaw only gets down to 3/8".

Here's something that I don't see often, the pinion faces have a bare machined finished (no functional importance of course).

The one I got the jaws don't mesh near as well as my Bison, you can see the two jaws in the lower right corner is even worse. Not sure if it was a grinding issue or if it's because of all that crap inside of it. Hopefully it does clean up & goes away.

Since I bought this to use on a rotary table I have no way of measuring run out since I don't have a backplate for it & I won't be making one for the lathe. My 3 jaw that came with the lathe is 6" so the backplate is too small.

I decided to try something, not something I would trust as there's too much error involved but it gave me a rough measurement with what I had on hand.

I chucked up a piece of Thomson shafting that I use for checking runout in the 4-jaw & indicated. Was going to try clamping the 6-jaw on the end.

Not sure why but I was getting weird readings so I decided to try the same with my Bison which worked better.

I estimate about just under .002" runout, measuring the register on the back & the body was about the same. The register is not machined very smooth. Crappy phillips screws holding the back cover & set screws for the pinion but no surprise there. Typical cheap tiny chuck key which I always just toss in a box anyway. They did include a microfiber cloth with machining related pics on it for cleaning, never seen that before.

So my thoughts on a quick evaluation, typical you get what you pay for with Asian import stuff. Will I keep it? Yes. Would I buy it again knowing what I know now? Probably not, but with some work it might turn out to be a decent chuck, good enough for me to use on the rotary table anyway. We'll see after I spend some time on it to go through & clean up everything, I'm a bit scared to see what it looks like inside.

The Fuerda/Gator semi steel 6-jaw would be a much better buy for a couple hundred more & it's adjustable.

- Joined

- Nov 16, 2012

- Messages

- 5,596

Good review DZ.

All in all, the chuck seems OK but the real test will be after you clean it up. Please do me a favor and run at different speeds and check balance. The backplate may need to be rotated to find the sweet spot (if it has one).

Ray

All in all, the chuck seems OK but the real test will be after you clean it up. Please do me a favor and run at different speeds and check balance. The backplate may need to be rotated to find the sweet spot (if it has one).

Ray

- Joined

- Nov 16, 2012

- Messages

- 5,596

Also interested in how it cleans-up... No hurry now, DZ... No pressure coming from me :lmao:.

Anyhow, I'd never expect a Chevy Cavalier to perform like a Corvette but then again, the 250% price difference is about the same differential of a Gator 6 jaw. If you calculate the price difference for every thousandth inch of runout difference, I wonder what the ratio is. Looking at it in those terms, I think you got a good deal -especially if you get the TIR down around 0.001 or 0.002 without too much struggle. That's about as good as you'll get from most scroll chucks. It might cost you a couple hours but you'll keep 500 bucks in your wallet.

Ray

Anyhow, I'd never expect a Chevy Cavalier to perform like a Corvette but then again, the 250% price difference is about the same differential of a Gator 6 jaw. If you calculate the price difference for every thousandth inch of runout difference, I wonder what the ratio is. Looking at it in those terms, I think you got a good deal -especially if you get the TIR down around 0.001 or 0.002 without too much struggle. That's about as good as you'll get from most scroll chucks. It might cost you a couple hours but you'll keep 500 bucks in your wallet.

Ray

- Joined

- Nov 27, 2012

- Messages

- 7,858

Spent like 4-5 hrs cleaning up the chuck today, longer than I have ever spent on an import chuck before. Lots of burrs & crap inside. Some of the burrs did not affect anything but I figure I might as well clean them up while I was at it. Took some pics to share.

Here's the back of the chuck. They used philips screws which I hate & one of them is stripped, not threaded in all the way.

They didn't bother to clean up the casting.

Here's what it looked like on the inside. Lots of fine debris mixed in the grease, looks like cast iron dust.

Took the jaws out, completely cleaned out the scoll, pinions, & body, still had very bad binding when turning. Thought is was the scroll as it had some high spots on the front which I stoned out but it wasn't. Turns out it was one of the pinions. One of them was a 7 thou larger in dia than the other two. Threw it in the 4 jaw as it wasn't very concentric. Turned it down to size & it fixed the problem, scroll was rotating smooth now.

Chuck body all cleaned out & added a bit of oil for the scroll.

Cleaned all that unknown dirty crap they used for grease & applied some fresh Gleitmo 805 grease.

Not that it really mattered but the back plate was like 150 thou smaller than the through hole of the chuck. The chuck through hole is 1.77" so I bored the back plate to match. Just got a Starrett 670 ID attachment recently & figured I might as well try it out. I normally just use a DTI but sometimes it's quicker to just use a dial indicator.

Also gave it a chamfer to clean up the ugly casting.

Replaced those cheap philips screws with SHCSs.

There were lost of the burs on the top & master jaws, specifically on the tongue & grooves (forgot to take pics). Most of it didn't affect anything but I spent the time to debur it all. All the bolts for the top jaws are standard thread like my Fuerda 4 jaw & Bison 6 Jaw.

Here it is on my RT. My back plate will arrive tomorrow but I'm going out of town for a week so that'll have to wait.

Overall I'm happy with the way it cleaned up. Unfortunately the gaps in the jaws didn't get any better but I'm not worried about it.

Here's the back of the chuck. They used philips screws which I hate & one of them is stripped, not threaded in all the way.

They didn't bother to clean up the casting.

Here's what it looked like on the inside. Lots of fine debris mixed in the grease, looks like cast iron dust.

Took the jaws out, completely cleaned out the scoll, pinions, & body, still had very bad binding when turning. Thought is was the scroll as it had some high spots on the front which I stoned out but it wasn't. Turns out it was one of the pinions. One of them was a 7 thou larger in dia than the other two. Threw it in the 4 jaw as it wasn't very concentric. Turned it down to size & it fixed the problem, scroll was rotating smooth now.

Chuck body all cleaned out & added a bit of oil for the scroll.

Cleaned all that unknown dirty crap they used for grease & applied some fresh Gleitmo 805 grease.

Not that it really mattered but the back plate was like 150 thou smaller than the through hole of the chuck. The chuck through hole is 1.77" so I bored the back plate to match. Just got a Starrett 670 ID attachment recently & figured I might as well try it out. I normally just use a DTI but sometimes it's quicker to just use a dial indicator.

Also gave it a chamfer to clean up the ugly casting.

Replaced those cheap philips screws with SHCSs.

There were lost of the burs on the top & master jaws, specifically on the tongue & grooves (forgot to take pics). Most of it didn't affect anything but I spent the time to debur it all. All the bolts for the top jaws are standard thread like my Fuerda 4 jaw & Bison 6 Jaw.

Here it is on my RT. My back plate will arrive tomorrow but I'm going out of town for a week so that'll have to wait.

Overall I'm happy with the way it cleaned up. Unfortunately the gaps in the jaws didn't get any better but I'm not worried about it.

- Joined

- Nov 3, 2013

- Messages

- 405

Fantastic writeup DZ.

It looks pretty decent after you did the rest of the manufacturer's job for him.

And did it correctly!!!

Seems that's the price you pay for the price you pay.

Thanks a ton for taking the time to report on your experience. I appreciate it.

It looks pretty decent after you did the rest of the manufacturer's job for him.

And did it correctly!!!

Seems that's the price you pay for the price you pay.

Thanks a ton for taking the time to report on your experience. I appreciate it.

- Joined

- Nov 27, 2012

- Messages

- 7,858

Fantastic writeup DZ.

It looks pretty decent after you did the rest of the manufacturer's job for him.

And did it correctly!!!

Seems that's the price you pay for the price you pay.

Thanks a ton for taking the time to report on your experience. I appreciate it.

No problem, it was fun, & I'm glad it was worthwhile. Thanks!