-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Asroba/meyer & Burger UW1

- Thread starter MattM

- Start date

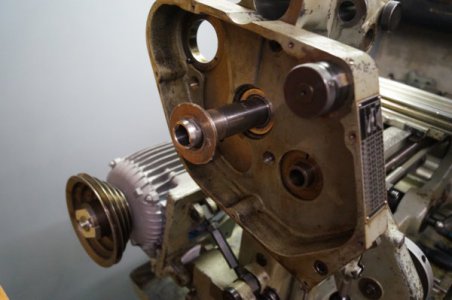

Been working on this @#!#% machine for hours. Heat, Kroil, leverage, impact, cursing, nothing is working. Am I missing something? Is there something other than threads holding the bull gear on? Damn, wish I had a schematic .

'bout ready to sell it for scrap. Any offers above scrap?

What really bugs me about this is that I have rebuilt many machines and have never had close to this much trouble removing a part; even on 100 year old rusty farm equipment and there is not a spot of rust on this piece.

Talk me off the ledge.

It is the large gear that drives the spindle.

'bout ready to sell it for scrap. Any offers above scrap?

What really bugs me about this is that I have rebuilt many machines and have never had close to this much trouble removing a part; even on 100 year old rusty farm equipment and there is not a spot of rust on this piece.

Talk me off the ledge.

Wich one you mean with "bull gear"? Do you have pictures?

It is the large gear that drives the spindle.

Spray it with oil, cover it with a plastic bag so your garage doesn't stink too bad, and then ignore it until next weekend. Frustration will lead to breaking things and you aren't going to find replacement parts. Other people have taken the bearings out, so wait until you find someone who can guide you.

- Joined

- Oct 7, 2017

- Messages

- 16

Hello Matt

I hope i can help you a little bit...

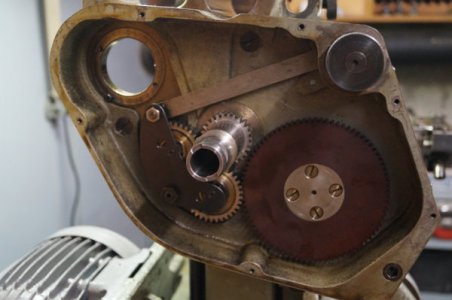

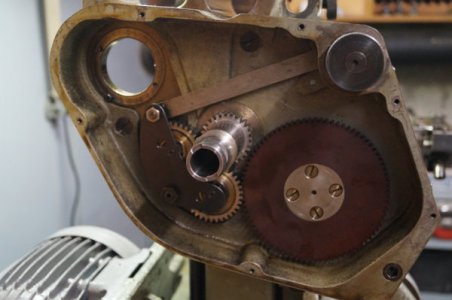

First, you have to loose this litle allen screw in this locknut. Then you can loosen the locknut.

Then you can pull off the Bullgear and the piece on which the locknut was on it together!

Theres no thread on the Bullgear, it is just a feader key on the shaft. The feader key you can press of with an M3 screw, after the Bullgear is down.

PDF from the drawing of spindle

I hope i can help you a little bit...

First, you have to loose this litle allen screw in this locknut. Then you can loosen the locknut.

Then you can pull off the Bullgear and the piece on which the locknut was on it together!

Theres no thread on the Bullgear, it is just a feader key on the shaft. The feader key you can press of with an M3 screw, after the Bullgear is down.

PDF from the drawing of spindle

Attachments

- Joined

- Oct 7, 2017

- Messages

- 16

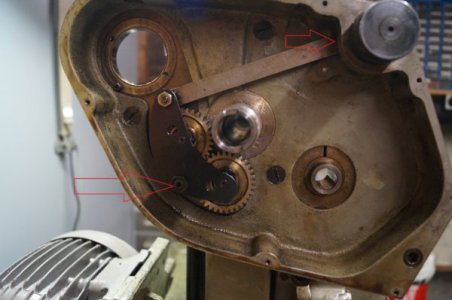

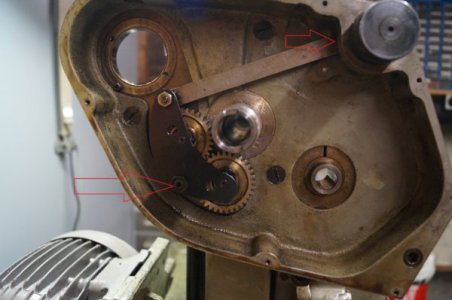

After you got that, you have to remove the "Wendeherz" (i dont know the name on english) an the litle gear on the right side.

The "Wendeherz" you can remove by this nuts (with the red arrow). The little gear you can pull by hand without loosing something (if i remember correctly) But watch out, there are loose needle roller bearings on it. You can loose theese very fast, if you pull the gear out. Dont aske me from where I know that...

The "Wendeherz" you can remove by this nuts (with the red arrow). The little gear you can pull by hand without loosing something (if i remember correctly) But watch out, there are loose needle roller bearings on it. You can loose theese very fast, if you pull the gear out. Dont aske me from where I know that...

- Joined

- Oct 7, 2017

- Messages

- 16

Last edited:

Spray it with oil, cover it with a plastic bag so your garage doesn't stink too bad, and then ignore it until next weekend. Frustration will lead to breaking things and you aren't going to find replacement parts. Other people have taken the bearings out, so wait until you find someone who can guide you.

Very good advice. I have been spraying it with Kroil for over a week. That's not a garage, it's my shop. The sweet smell of machine oil hangs heavy most of the time.

I'm thinking on making a special tool that I can attach an impact wrench to.

Micron---You said the magic words, "No thread on the bullgear". How I can stop trying to unscrew it.

I did remove the small gear up and to the left. In the pic it is just sitting loosely in place. It is not hindering the removal of the bullgear in any way. I also tried once before to remove the gear with a gear puller. I'm going to try again straightaway. Stand by.

You have been a great help. Thank you. If you are ever in this territory I'll you a pint or a bottle of our wine.---Matt

I did remove the small gear up and to the left. In the pic it is just sitting loosely in place. It is not hindering the removal of the bullgear in any way. I also tried once before to remove the gear with a gear puller. I'm going to try again straightaway. Stand by.

You have been a great help. Thank you. If you are ever in this territory I'll you a pint or a bottle of our wine.---Matt

Success. Thanks to Mikcron 91. Mikron make that two (or more) pints.

I notice that is a phenolic gear and three teeth are broken. I guess there is little to no chance of finding a replacement. Is it worth it to make one or should I just live with the broken teeth?

I notice that is a phenolic gear and three teeth are broken. I guess there is little to no chance of finding a replacement. Is it worth it to make one or should I just live with the broken teeth?

After digging further into this beast I have taken a decision to sell or part it out. I don't have the time or inclination to do this restoration. I'll leave it to someone else. Price is very negotiable. Trades?

With that being said here is what is wrong with it: three broken teeth on the bullgear, a broken tooth on a small metal (idler?) gear, a broken tooth on another phenolic gear which looks to be the lead screw gear, a broken cast iron piece on the compound looks like it would be easy for anyone her to fabricate out of aluminum. No guarantees other things are not wrong with it.

Pictures will be forthcoming but might take awhile. Lot of pics and I want to clean it up before presenting. We are leaving for a 10 day vacation Friday.

If anyone is close by and wants to stop by and take a look PM or give me a call.

With that being said here is what is wrong with it: three broken teeth on the bullgear, a broken tooth on a small metal (idler?) gear, a broken tooth on another phenolic gear which looks to be the lead screw gear, a broken cast iron piece on the compound looks like it would be easy for anyone her to fabricate out of aluminum. No guarantees other things are not wrong with it.

Pictures will be forthcoming but might take awhile. Lot of pics and I want to clean it up before presenting. We are leaving for a 10 day vacation Friday.

If anyone is close by and wants to stop by and take a look PM or give me a call.