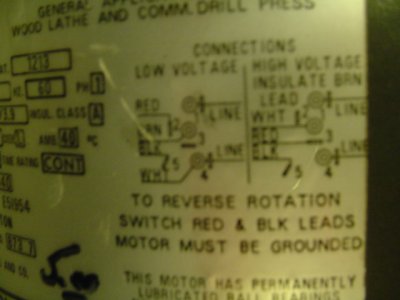

A year or two ago, I acquired an old (1952?), beat up, disgusting looking Atlas 1010 benchtop drill press. I tore it all down and cleaned it up and painted it. It looks like new. I found a multi step pulley for the motor and only had to make a bushing to get it to fit the original motor. Now that I have the whole thing back together, I need to hook up a new power cord. EEK! There are three terminals on the motor. I have a pair of wires coming from the on/off switch and a pair of wires for the line cord. I am an electrical engineer by trade and I could easily figure this out if I took the motor apart to see where the wires went inside the motor. I really don't want to bugger up the paint job on the motor by tearing it apart again. I have tried to use an ohm meter but that is no help as there are meter reading between all of the terminals.

If anyone has an an Atlas 1010 drill press, I would appreciate knowing how the power is hooked up.

Thanks,

Earl

If anyone has an an Atlas 1010 drill press, I would appreciate knowing how the power is hooked up.

Thanks,

Earl