- Joined

- Jun 11, 2022

- Messages

- 5

(first post)

I recently purchased a 3950 that appears to have seen little use but needs disassembly and cleaning.

First problem so far is the split nut lever is very difficult to turn. I've removed the split nuts and the spring/ball detent and sprayed WD-40 inside. Was able to move the lever, but still very hard.

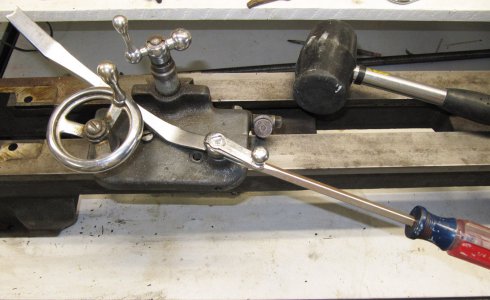

It looks like the split nut cam (part #M6-38) has a square end that the lever is pressed on and might have been peened to retain (picture attached).

I assume driving the split nut cam out is the way to go for disassembly, but perhaps someone out there has some advice to offer to avoid damage and/or some assembly advice. Bang away with a brass punch or make a pushing tool? It sure looks like a place for a threaded fastener alteration for reassembly.

Thanks in advance for any help

I recently purchased a 3950 that appears to have seen little use but needs disassembly and cleaning.

First problem so far is the split nut lever is very difficult to turn. I've removed the split nuts and the spring/ball detent and sprayed WD-40 inside. Was able to move the lever, but still very hard.

It looks like the split nut cam (part #M6-38) has a square end that the lever is pressed on and might have been peened to retain (picture attached).

I assume driving the split nut cam out is the way to go for disassembly, but perhaps someone out there has some advice to offer to avoid damage and/or some assembly advice. Bang away with a brass punch or make a pushing tool? It sure looks like a place for a threaded fastener alteration for reassembly.

Thanks in advance for any help