-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas 618 feed handle

- Thread starter TechNova

- Start date

- Joined

- Sep 5, 2013

- Messages

- 3,212

I was suspecting as much. I have two of these machines and unless one takes great care in removing the handle it is easily damaged to the point that re-peening will not work and a screw into the end would be a logical alternative. That said, it also gives you the freedom to choose whatever size you want as a replacement so you could still make something work, just not as clean as the original method.

- Joined

- Apr 30, 2015

- Messages

- 11,376

If the parts are really mangled you should replace one or both. Then, an alternative to peening the shaft would be to either:

1) Drill and tap a hole in the shaft for a screw and washer OR

2) Drill and tap the handle itself for a couple setscrews at 90 degrees (the method I would probably use)

-Mark

If you elected to do (1) I would use a coarse thread like 10-24 since the shaft is zamak alloy

1) Drill and tap a hole in the shaft for a screw and washer OR

2) Drill and tap the handle itself for a couple setscrews at 90 degrees (the method I would probably use)

-Mark

If you elected to do (1) I would use a coarse thread like 10-24 since the shaft is zamak alloy

- Joined

- Dec 25, 2011

- Messages

- 10,525

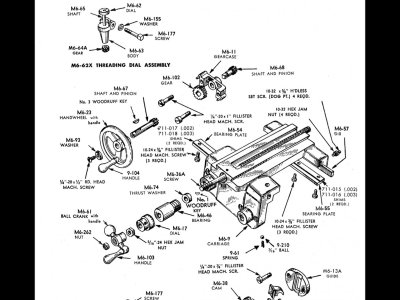

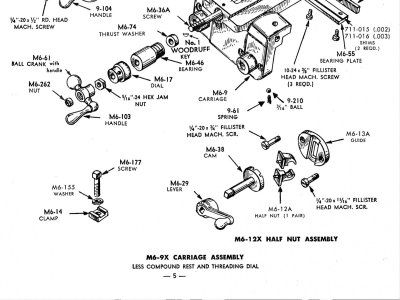

This is not a good candidate for two screws @ 90 deg. because it is critical that the front of the lever be firmly against the shoulder on M6-38 Scroll. The long and short of it is that the designers of the 6" machines did not intend for the scroll and lever to be reusable after original installation. The at least later production of the Atlas 10" and Craftsman 12" through 101.07403 have a #8-32 oval-head machine screw retaining the lever to the scroll so that both parts are reusable. I do not have drawings and dimensions of the 6" scroll shaft but at the expense of probably a new lever, one could convert the various 6" models to be reusable but I do not know whether one would be able to use a #6-40 machine screw or would have to make do with a #4-36 or #4-40.

- Joined

- Apr 30, 2015

- Messages

- 11,376

The peening technique is so totally dependent on the skill of the operator I hesitate to recommend it

IMO setscrews couldn't be much worse than some butchery I've seen

IMO setscrews couldn't be much worse than some butchery I've seen